Electroplating is the process of plating a thin layer of other metals or alloys on the surface of certain metals using the principle of electrolysis. It is a process of using electrolysis to attach a layer of metal film to the surface of metal or other material parts to prevent Metal oxidation (such as rust), improve wear resistance, electrical conductivity, reflective properties, corrosion resistance (copper sulfate, etc.) and enhance the appearance. The outer layer of many coins is also electroplated. Since the electroplating process, bath solution, etc. cannot be controlled in absolutely consistent conditions, there will be more or less the problem of color difference.

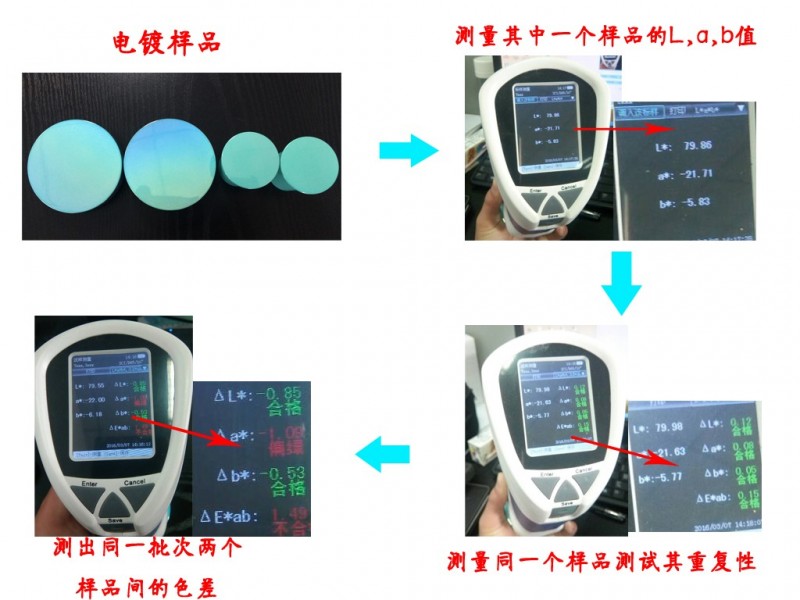

According to the customer's requirements for accuracy, etc., we use the precision color difference meter CS-210 to measure the color difference between different samples of the same batch. CS-210 has its own camera viewfinder function, which can accurately locate the measurement position and make the measurement easier!

After black-and-white calibration, two measurements were taken on a single sample to test the repeatability of the instrument. Then compare the color difference between the two samples from the same batch.

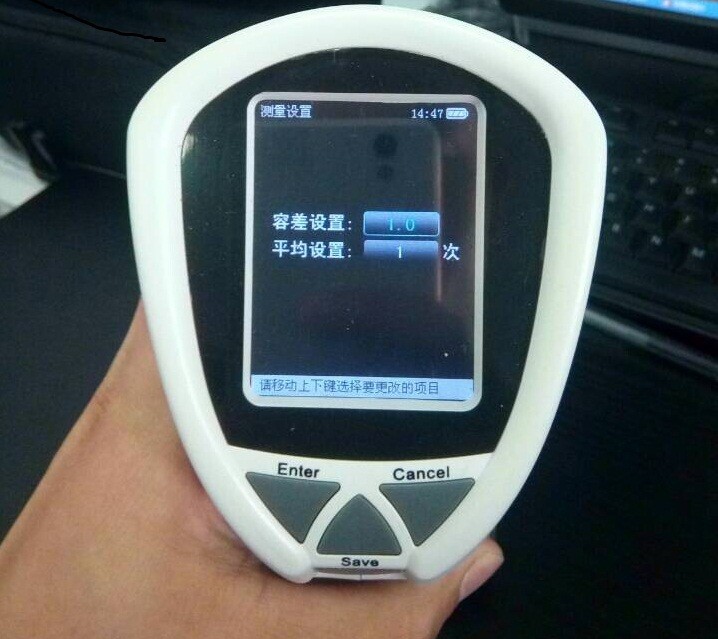

If there is a requirement for tolerance in the industry, the tolerance needs to be set.