(1) Advantages

1. The atomization is sufficient, and the appearance and decoration effect of the coating film is good

In the process of electrostatic spraying, the negatively charged paint particles after mechanical atomization repel each other and become more dispersed and more uniform, so the formed coating film is very fine and has good decorative appearance, so it is very suitable for topcoat decorative construction.

2. High paint utilization rate

Due to the attraction of the electric field, the charged paint mist is effectively adsorbed and deposited on the surface of the workpiece. Not only the adhesion rate is high, but also it is evenly distributed on the entire surface. The utilization rate of the paint can reach more than 8o%, so the paint is saved.

3. Less paint mist scattering

Compared with air spraying and high-pressure airless spraying, the flow speed of paint mist particles is slower, but the paint mist is much less scattered, so the working environment conditions are improved, which is beneficial to the health of workers.

4. High painting production efficiency

Suitable for automated mass production, the maximum speed of the electrostatic coating transport chain can reach 24m/min, which is 6 times that of manual spraying.

5. Good spraying effect on the corners of complex workpieces

Due to the tip effect of the charge, the charge density at the corners of the workpiece is high, and the deposited coating film is thick, and the coating film still has sufficient thickness after drying under the action of surface tension.

(2) Disadvantages

1. There are specific requirements for the conductivity of coatings and solvents, and the volatility of solvents

1. There are specific requirements for the conductivity of coatings and solvents, and the volatility of solvents

Sometimes in order to meet the requirements of electrostatic spraying, it is necessary to change the composition of the paint. Moreover, the workpiece to be coated needs to be a conductor, so it is mainly suitable for spraying metal workpieces with good conductivity. For non-conductors such as plastics and wood products, corresponding measures (such as soaking in special solvents or covering a layer of conductive film) are required. Only after electrostatic spraying.

2. The uniformity of the coating is greatly affected by the size and shape of the workpiece

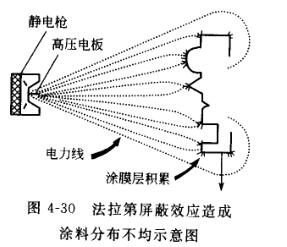

Due to the influence of electric field shielding or uneven distribution of power lines, it is difficult to guarantee the spraying quality of workpieces with complex shapes, and manual respraying is sometimes required. In electrostatic spraying, the uneven distribution of paint on the workpiece is caused by the Faraday shielding effect, as shown in Figure 4-30. There is more paint distribution on the corners, protruding parts, corner tops and sharp edges of the workpiece, but less on the concave parts.

3. There is a hidden danger of fire caused by electric sparks when working in a high-voltage electric field

There are strict regulations on safe operation in electrostatic spraying work. For example, the conveying equipment and the workpiece to be painted should always be in a good grounding state, but the paint delivery pipeline cannot be grounded when spraying conductive paint.