Too much or too little resistance of the paint will affect the effect of electrostatic spraying. The coating with too much resistance has a low charging rate during the electrostatic spraying process, while the coating with good conductivity and low resistance will disappear too quickly after being charged, and the static voltage will not increase, which will also affect the spraying effect. When the conductivity of the coating is too strong, the current intensity of the system is high, and the wrapping effect of electrostatic spraying is poor, and the paint mist particles cannot fall to the back of the coated workpiece to affect the coating effect. Studies have shown that some coatings are easy to charge, and some are not easy to charge. This has a lot to do with the nature of the resin in the coating. For example, melamine resin has good conductivity, alkyd resin has certain conductivity, and epoxy resin has good conductivity. Poor electrical conductivity. The properties of the pigments and solvents in the paint also have a great influence on the conductivity of the paint.

In addition to its nature, the conductivity of pigments is also related to its particle shape. Generally, the finer the particles, the better the conductivity. Therefore, the pigments with diamond-shaped particles and spherical particles should be ground very finely. Coating factories generally do not produce coatings directly used for electrostatic spraying, but they can provide solvents added to the coatings during electrostatic spraying. Adding these solvents to ordinary coatings can make it into a coating for electrostatic spraying. Electrostatic spraying should use paint that is easy to charge, and the general resistivity is 5~50MΩ·cm is more suitable. For coatings with poor conductivity above 100MΩ·cm, it is necessary to add a polar solvent (such as diacetone alcohol) to improve the conductivity of the coating, but it should be noted that the amount added should be appropriate, adding too much will affect the covering of the coating strength and durability. For paints with too low resistivity such as water-based paints and metallic flash paints, non-polar solvents need to be added to increase its resistance.

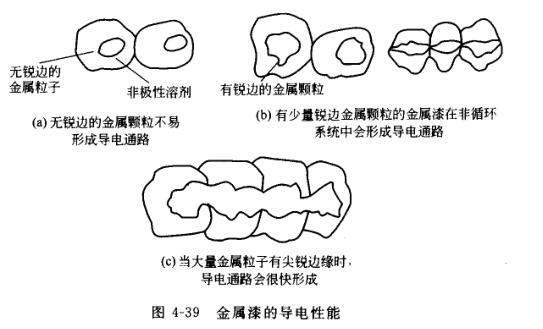

Metal powder has strong conductivity, adding non-polar solvent to separate and surround the metal powder particles can reduce its conductivity, but this separation and surrounding effect has a lot to do with the shape of the metal particles, for those without sharp corners The round particles are easier to be separated and surrounded. After the high voltage is applied, the metal powder will not be connected to form a conductive path, but if the metal particles have sharp edges and are used in a non-circulating electrostatic spraying system, it will be difficult. It is easy to break through the separation and encirclement of the solvent to form a conductive path, and the more sharp corners are, the easier it is to form a conductive path. Therefore, when using metallic paint for electrostatic spraying, not only non-polar solvents should be used, but also the circulation system should be used as much as possible, and the metal particles should be ground to remove edges and corners. Figure 4-39 shows the conductivity of the three types of metallic paints.

In addition, the paint container needs to be well insulated from the ground in order to carry out electrostatic spraying.

At present, the most widely used coating for electrostatic spraying is amino alkyd coating. Ordinary amino alkyd paint needs to adjust the resistivity to be below 100MΩ·cm before electrostatic spraying. At present, there is a diluent specially used to dilute amino alkyd coatings for electrostatic spraying in CHINA. First use it to reduce the resistivity value of the coating to 20~30MΩ·cm, and then use xylene to adjust the viscosity to an appropriate level. In addition, the requirements for the conductivity of the coating are also related to the electrostatic spraying equipment used. For example, when using a rotary (round) disc or rotary cup electrostatic coating equipment, the atomization in this system mainly depends on the interaction between particles with the same charge. Repulsion, and only the highly conductive paint is easy to charge, so adding a strong polar solvent to the paint to improve its conductivity is beneficial to improve the atomization degree of the paint. The mist particles thrown off the rotating (circular) disk or rotating cup by the coating with poor conductivity are mostly elongated. If the electrification is not good, the degree of atomization is low, and the coating will have disadvantages such as orange peel. The coating with good conductivity has a good atomization degree, and the particles become very round and more uniform in size, thus greatly improving the surface coating quality. However, in the electrostatic spraying that uses compressed air or hydraulic pressure to atomize the paint, the conductivity of the paint is too strong, which will instead make the paint mist a conductive path and reduce the voltage value at the end of the Spray Gun, so a low-polarity solvent is usually used. Practice has proved that in portable electrostatic spraying, the lower the conductivity of the paint, the better the effect of electrostatic spraying.

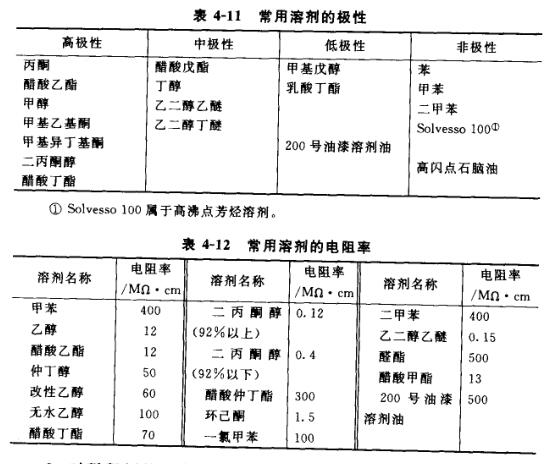

Among the solvents commonly used to change the conductivity of coatings, non-polar or weakly polar solvents are mainly mineral spirits, naphtha, fat lamps, aromatic lamps (toluene, xylene) and other lamp solvents. Among the medium-strength polar solvents are ethyl acetate, butyl acetate, cyclohexanol, polyethylene glycol diethyl ether, cyclohexanol, etc. Strong polar solvents include methanol, ethanol, methoxyethanol, isopropanol, diacetone alcohol and other alcohols, methyl ethyl ketone, methyl isobutyl ketone, acetone and other ketones, 1-nitropropane, 2-nitropropane, etc. Acid solvents such as nitro compounds and methyl acetate. The polarity of commonly used solvents for electrostatic spraying is shown in Table 4-11. The resistivity of commonly used solvents is shown in Table 4-12.