Defelsko PosiTector 6000涂层测厚仪是测量胶印设备的关键尺寸的称心仪器。它提供快速简单的覆盖层,包装和板厚度测量,确保良好的打印质量和较低的维护成本。

应用

胶印是一种常见的印刷技术,油墨图像从一个滚筒传递或“抵消”到另一个覆盖有胶皮(橡皮布)的滚筒。这样就将图文 从胶皮传递到印刷表面。

从胶皮传递到印刷表面。

此技术用于打印纸、装饰板、报纸、杂质、商业表单、信封、纸板箱、邮票、塑料杯和装饰金属。

一个图像从金属板有效地传递到胶皮上要求在金属和橡皮布盖滚筒之间的接触点的压力或“挤压”是一致。

这是通过在胶皮下面增加一个额外的包装材料(例如,纸或纤维)厚度来完成,以确保胶皮铺展超过滚筒。这迫使胶皮能够在接触点与金属板圆筒触碰。

另一种方式来思考,包装确保滚筒半径重叠使得滚筒总是在它们的接触点相互推动。

这种额外的厚度或重叠,称为挤压,通常是0.004至0.006英寸(4-6密耳或0.1-0.2毫米)。它对打印质量其重要性不言而喻。如果挤压力太低,图像将不能有效地转移;如果它太高,印刷点会模糊或弄脏。

这种额外的厚度或重叠,称为挤压,通常是0.004至0.006英寸(4-6密耳或0.1-0.2毫米)。它对打印质量其重要性不言而喻。如果挤压力太低,图像将不能有效地转移;如果它太高,印刷点会模糊或弄脏。

在操作时,印刷胶覆盖层和在它下面的包装材料受到恒定的压缩,逐渐减小两层的厚度。因此,关键的挤压尺寸需要定期检测,以确保有效的打印质量。

橡胶布一般持续3到6个月,这取决于印刷机的类型和印刷机的工作性质。胶皮层的厚度需要定期测量,以实现一致的打印质量,并确定胶皮什么时候需要更换。

传统的测量方法

常规的模拟式“针”工具常用于测量在使用的胶皮/包装厚度。两个针穿透到印刷层,并与包装下面的滚筒金属表面电接触。

不幸的是,穿孔的胶覆盖层会造成损坏,影响印刷质量。化学溶剂会渗透到穿刺孔,导致在胶覆盖层下膨胀的包装材料有斑点,造成图像模糊。

Defelsko解决方法

DeFelsko PosiTector 6000涂层测厚仪是用于测量在使用胶皮层、包装和板厚度的称心工具。这种手持测量仪比传统的针具有以下几个优势:

1. Since it uses the principle of magnetic induction or eddy current, it is non-destructive and will not leave any pinholes in the rubber layer.

2. The Thickness Gauge can be used on the entire drum width.

3. It can be measured regularly and easily, and the built-in statistical program can continuously update and display the average value measured on the entire surface.

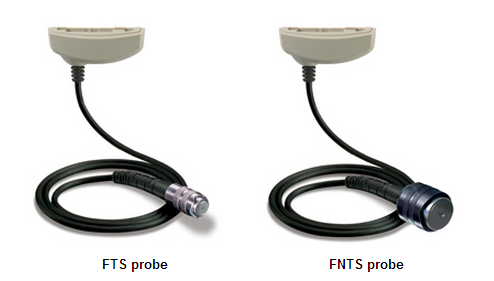

4. Probes for various applications are available, including miniature probes for hard-to-reach places.

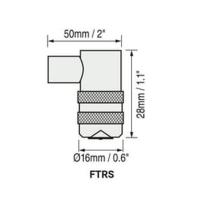

The PosiTector 6000 FTS probe is suitable for determining the thickness of blanket, packaging, and board material on steel press cylinders. If the cylinder of the offset printing machine is stainless steel or aluminum, the FNTS probe should be used.

These replaceable probes are capable of measuring thickness from 0 to 250mil (6mm) with a maximum accuracy of ±0.5mil (0.01mm) + 1% of reading.

The storage and download capabilities of the PosiTector 6000 allow operators to track overlay/package compression and wear over time and record how they are affected by different print runs and operations. Through experimentation, it is possible to use the positector 6000 to measure optimized printing conditions and better predict when the blanket needs to be replaced.

Remarks: This article comes from Defelsko and is professionally translated by NBCHAO Mall. The source must be indicated when the translation is reproduced.