1. The principle of heating spraying

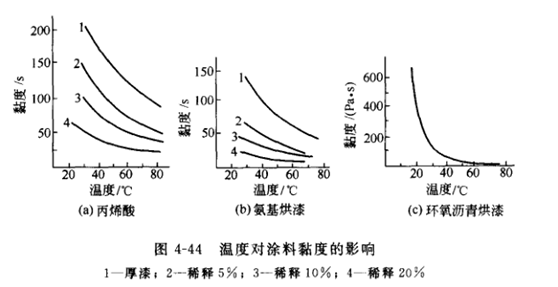

Heated spraying is a process in which the paint is heated and kept at a relatively high temperature to greatly reduce the viscosity of the paint, and then atomized by air spraying, high-pressure airless spraying or electrostatic spraying. All coatings undergo significant changes in both kinematic and dynamic viscosity when heated to elevated temperatures. From the viscosity-temperature curves of various coatings in Figure 4-44, it can be seen that since the ambient temperature of spraying construction in different seasons is often changed, the viscosity of the same dilution degree of coatings also changes, which will bring adverse effects to the spraying process. Therefore, adjusting the temperature by heating can not only reduce the viscosity of the coating, but also ensure the stability of the viscosity, so that the coating quality can be kept consistent for a long time. Since the viscosity of the paint does not decrease much with the temperature after the temperature exceeds 50°C, it is generally sufficient to heat to 50°C, and the maximum does not exceed 70°C.

2. Characteristics of heating spray

When using solvent-based coatings for spraying, in order to reduce the viscosity of the coatings, it is necessary to dilute with organic solvents. In order to achieve the viscosity required by the process, sometimes a large amount of diluent needs to be added. The thinner required to achieve the same viscosity can be greatly reduced when heated spraying is used, and generally about 30% less thinner can be used. When spraying, the solid content in the paint is greatly increased, which can bring the following benefits.

① Less or no diluent is added, which reduces the environmental pollution caused by solvent volatilization, and also reduces the expenditure caused by solvents.

②Increasing the solid content of the coating during spraying can reduce the number of spraying times, increase the thickness of the coating film, and shorten the coating cycle.

③ It can keep the viscosity of the paint constant during spraying. Due to the influence of the ambient temperature, the viscosity of the paint can remain unchanged, thus ensuring the uniform thickness and appearance of the coating film.

④It is beneficial to avoid the occurrence of sagging. Studies have shown that the temperature of the paint will drop significantly due to the volatilization of the solvent during the atomization process and the spraying process, and the higher the air pressure or hydraulic pressure during atomization, the more obvious the temperature drop. Therefore, when spraying at room temperature, the temperature of the paint mist will be below room temperature. Low temperature will further slow down the evaporation rate of the solvent in the paint, so the amount of residual solvent in the formed coating film is large and prone to sagging. If the temperature of the coating film drops below the dew point of water vapor, the water vapor will Condensation occurs on the surface of the coating film, which is not conducive to the adhesion of the sprayed coating on the workpiece and sags. In the heating spraying process, although the volatilization of the solvent in the atomization and spraying process also causes the temperature to drop, causing the solvent volatilization to slow down, but practice shows that when the coating film is formed

The temperature is still high, which is conducive to maintaining a certain volatilization speed of the solvent. The low solvent content in the coating film also reduces the possibility of water vapor condensation, so the coating is not easy to sag, so heating spraying is conducive to improving the coating. The leveling of the film improves the gloss of the coating film.

⑤Due to the reduction in the amount of solvent used, the hydraulic pressure used in high-pressure airless spraying is reduced, which reduces the splash and rebound of paint mist, and improves the utilization rate of paint.

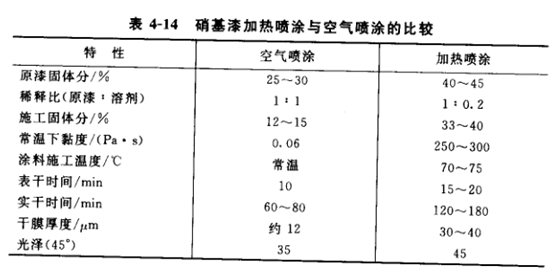

The advantages of heating spraying applied to quick-drying coatings such as nitro lacquer are obvious. As shown in Table 4-14, when the nitro paint is sprayed with heated air, the solid content of the paint is increased, the dilution ratio is reduced (the amount of solvent added is reduced), the viscosity is reduced, the film thickness is increased, and the gloss is improved. However, it should be noted that heating spraying is not suitable for spraying construction of poor thermal stability coatings such as water-based paints and two-component coatings.