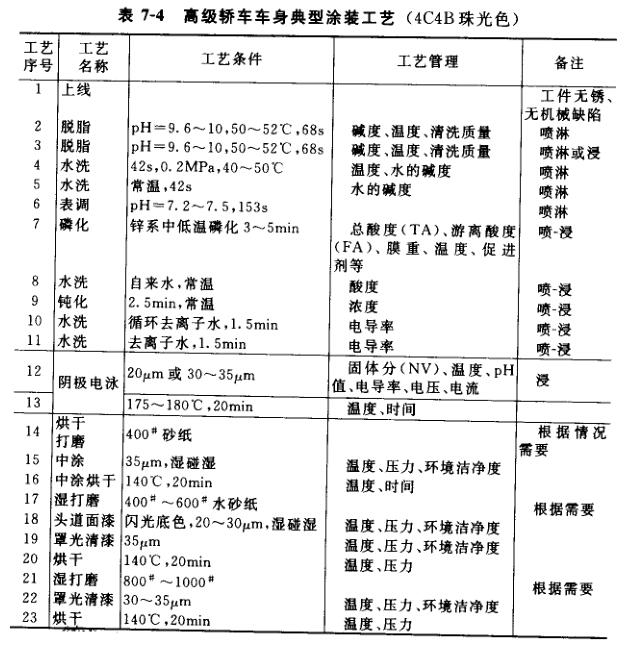

The coating of the car body is a composite coating. For the body of high-end cars with high decorative requirements, the coating system is 4C4B or even 5C5B, that is, primer, intermediate paint, topcoat and finish paint (1~2 times) for a total of 4~5 times. times and bake 4~5 times. The general car adopts 3C3B coating system, which is applied and baked primer, middle coat and top coat respectively. For trucks, jeeps and buses that have higher requirements for protection and lower requirements for decoration, the 2C2B coating system is used, that is, the primer and topcoat are applied and baked separately. Each coating has clear requirements for coatings and processes. See Table 7-4 for the coating process of limousine body.

1. Primer coating process

Automotive primer is the first paint that is directly painted on the surface of the workpiece after surface pretreatment, and is the basis of the entire coating. The requirements for the automotive primer are: it should have good adhesion to the surface of the workpiece after surface pretreatment, and its paint film needs to have excellent physical and mechanical properties and good corrosion resistance, water resistance, and chemical medium corrosion resistance It has good compatibility with intermediate paint or top coat, and has good construction performance.

Commonly used automotive primers include anodic electrophoretic primers, cathodic electrophoretic paints, solvent-based primers, water-based dipping primers, and powder coating primers. In occasions with high anti-corrosion requirements, cathodic electrophoretic coatings and solvent-based epoxy phenolic and epoxy amino primers should be used. Environmentally friendly water-based cathodic electrophoretic coatings are used for cathodic electrophoretic painting in large-scale assembly line production; in small-scale operations, due to the large investment in cathodic electrophoresis equipment and the poor stability of the bath, it will affect economic benefits, and it is better to use solvents Non-toxic epoxy baking paint, two-component epoxy primer can be used when baking conditions are not available. Therefore, the spraying process is less used in the primer process, and it is only used in small-scale production of spraying solvent-based primers. The film formers used in solvent-based primers include phenolic resins, alkyd resins, epoxy resins, epoxy-polyamide resins, and epoxy-polyurethane resins. The antirust pigments used include iron oxide red, etc. The solvent-based primer can be self-drying or drying, and the construction is simple. It can be sprayed or dipped. Air atomization spraying equipment is mainly used for spraying.

2. Intermediate coating process

The intermediate paint is a coating paint between the primer and the top coat. The main function of the intermediate coating is to improve the flatness of the primer of the coated workpiece, create a good base for the topcoat layer, improve the vividness and fullness of the topcoat layer, and improve the decoration and stone chip resistance of the entire coating. sex. Middle and high-end cars with high decorative requirements require that the coating should be as bright as a mirror, the mirror image should be clear, and the distinctness of image should be above 0.8. Middle coating process. It is required that the formed intermediate coating has good filling and leveling performance, and can eliminate small defects such as scratches on the surface of the primer to be coated. The paint and topcoat are consistent or compatible, and there will be no problems such as peeling of the coating and "biting" by the topcoat solvent. The medium coating should also have good flattening and sanding properties. After wet sanding, a flat and smooth surface can be obtained. When not sanded, it can still form a smooth and smooth surface by its own flattening property, and has good stone chipping resistance. .

Commonly used film-forming substances in automobile paint are thermosetting resins such as epoxy polyester resin, alkyd-amino resin, polyester-amino resin, etc., and sometimes self-drying resins such as nitro and acrylic modified nitro are used resin. In addition, the types of environmentally friendly coatings such as powder intermediate coatings and water-based intermediate coatings currently in use are increasing, among which solvent-based and water-based polyester and polyurethane paints have good performance. At present, in mass production, the intermediate coating has generally adopted the electrostatic spraying process.

3. Finishing process

Automobile topcoat is the last layer of paint used in the multi-layer coating of automobiles, which directly affects the decoration, weather resistance and appearance of automobiles. Coatings that can meet the requirements of automobile weather resistance and appearance decoration mainly include three categories: amino baking varnish, acrylic baking varnish and two-component aliphatic polyurethane topcoat. When no pigments are added, their varnishes or varnishes are used, and when pigments or metal powders are added, they become base paints or metallic paints. The specific varieties used are alkyd-amino baking varnish, thermosetting acrylic-amino baking varnish, two-component acrylic-polyurethane paint, etc. In addition to the natural color paint, more and more metallic effect paint and metallic flash paint are used in the top paint of the car, which makes the appearance of the car more colorful and more in line with the aesthetics of consumers. It is formed by adding aluminum powder and pearlescent pigments to the varnish. At present, in mass production, electrostatic spraying process has been widely used for topcoat.