Defelsko manufactures hand-held, non-destructive ultrasonic Thickness Gauges designed for the non-destructive measurement of dry film thickness of coatings on plastics. Many industries currently use this non-destructive technique for quality monitoring programs.

Two models for measurements on plastic substrates:

1. PosiTector 200 B1 (standard type) is economical and commonly used to measure the thickness of the total coating system.

2. PosiTector 200 B3 (advanced type) can simultaneously measure the total coating thickness and the independent thickness measurement of up to 3 layers in a multi-coating system. It is also capable of outputting plots that facilitate detailed analysis of coatings.

Application 1: Measuring Total Thickness

Some plastic coating systems are applied in layers to achieve their desired purpose. PosiTector 200 B1 is a very satisfactory method for situations where the user only needs to know the final total coating thickness.

The PosiTector 200 is designed for use in measuring most ready-to-use plastic coating applications. With a measuring range of 13 to 1000 microns (0.5 to 40 mils), it is a satisfactory instrument for measuring the thickness of total coating systems. It requires no calibration adjustments for most tests, has mil/micron unit switching, and has a large, thick, impact-resistant polycarbonate display.

For those familiar with magnetic coating Thickness Gauges, using an ultrasonic coating Thickness Gauge is not only simple but intuitive. The measurement method is simple and non-destructive.

Application 2: Measuring Rough Coated Surfaces

Coatings on rough surfaces are challenging for any measurement method, and ultrasonic testing is no exception. The positector 200 Thickness Gauge is designed to handle these situations.

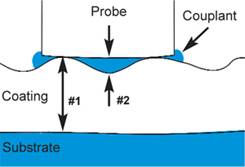

At the microscopic level, the thickness can vary (see Figure 2). Accurate thickness measurements are best obtained by taking multiple measurements at the same general location and then averaging the several test results.

Figure 1 Measuring a rough surface Figure 2 Couplant fills the gap between the probe and the substrate coating

On rough surfaces the positector 200 usually measures the thickness from the top of the coating peak to the substrate. The distance shown in Figure 2.

The couplant fills the gap between the probe and the coating to assist the penetration of the ultrasonic wear into the coating.

Severe roughness will cause the gage to display a low thickness value (distance #2). This is because the echo is stronger from the couplant/coating interface than the coating/substrate interface. The PosiTector 200 has a unique user adjustable set range feature to ignore rough echoes.

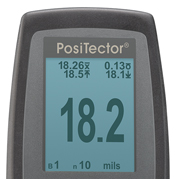

For these applications, the storage mode of the PosiTector 200 provides assistance. When memory is on, the PosiTector 200 counts and displays the number of measurement readings, the mean, standard deviation, and highest and lowest readings of those readings (see Figure 3). Using the provided couplant works better than water on rough surfaces.

Figure 3 To obtain accurate measured thickness values on rough surfaces, PosiTector 200's memory mode is used to calculate the average value of the measurements

Application 3: Measuring the thickness of individual layers in multi-layer applications

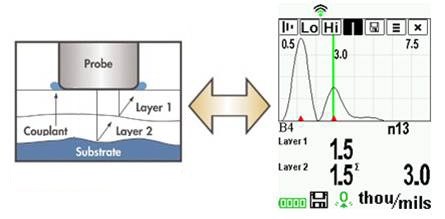

The PosiTector 200 B3 measures both the total coating thickness and individual thickness measurements of up to 3 layers in multi-coat systems. It is also capable of outputting plots that facilitate detailed analysis of coatings.

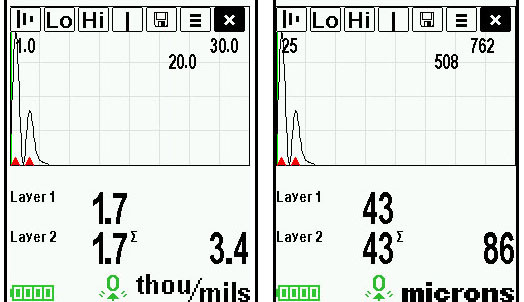

Figure 4

In the example above, Layer 1 is 1.5 mils thick. Layer 2 was 1.5 mil thick. Total thickness is 3 mils. The graphic LCD shows two "peaks", representing the two material interfaces. A two-step process was performed to condition the instrument for multicoat testing.

Application 4: Measurement of automotive plastics

A large number of plastic parts are currently used in the interior and exterior of automobiles. Often these plastic parts are painted for aesthetics and protection.

Measuring interior components such as dashboards, door panels, airbags, steering wheels, etc. is difficult for two reasons. First, many components are too small or complex in shape for the PosiTector 200 probe to access properly. Second, some parts are either too thinly coated or too rough to measure consistently. The gage is more accurate on smooth, flat, solid surfaces with coating thicknesses of 13 microns (0.5 mils) and above.

If the PosiTector 200 probe is able to touch the measuring surface again, external components such as bumpers, mirror housings, side cladding etc. can be measured. The Thickness Gauge is capable of measuring the total thickness of large logarithmic applications and can measure the total individual layer thickness of some multi-layer systems.

The automotive paint system consists of several coats. The basic positector 200 B1 model is capable of measuring these total coating thicknesses.

Adhesion promoter and primer layers in automotive applications are often too thin for individual measurements with the more advanced PosiTector 200 B3. Therefore, the instrument combines their thickness with the base coating thickness to produce an overall result. The top clear cover coat is measured separately.

Figure 5 is a typical result of PosiTector 200 B3 measuring automotive exterior plastics. The graph on the left shows demerits measured in imperial units (mils). The graph on the right uses equivalent measurements in metric units (microns). Although the coating system consists of 4 layers, the instrument measures the thickness of the first three layers (adhesion promoter, primer, primer) together to a value of 1.7 mils (43 microns). The final bottom clear coat alone was measured at 1.7 mils (43 microns). The total coating system thickness was 3.4 mils (86 microns).

Such results are useful when final clear coat thickness is important for coating determination. Auto detailing professionals take advantage of this feature to see how much clear coat remains while polishing. Painters use this feature to ensure consistent coating thickness.

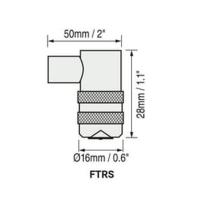

The ultrasonic probes discussed in this article are 8 mm (0.3 in) diameter flat measuring surfaces that should be fully in contact with the coated plastic for good measurement results. Measuring surfaces requires averaging multiple readings to get a meaningful result.

Remarks: This article comes from Defelsko and is professionally translated by NBCHAO Mall. The source must be indicated when the translation is reproduced.