Anti-drying shrinkage cracks (mudcracks) refers to the ability of the coating film to resist cracks caused by drying shrinkage. It refers to the cracks that appear during the drying process of the wet coating film, rather than the cracks that appear during the use of the film after drying.

1. Test method

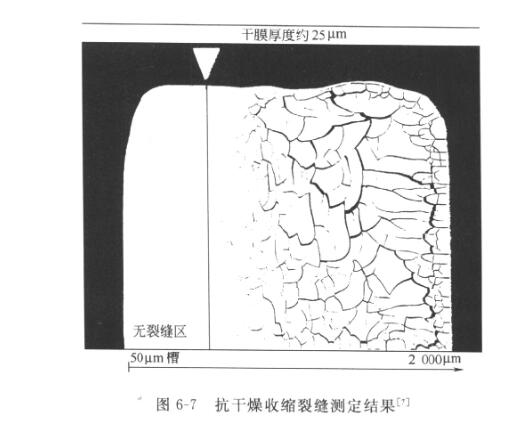

Anti-drying shrinkage cracks are usually coated with a wedge gap applicator. For example, the gap of the wedge gap applicator is from 50 to 2000 μm and the width is 156 mm. The wet film after coating is at (23 ± 2) ℃, RH -(50±5)% under the standard conditions of curing for 48h, and then observe at what thickness the dry film begins to crack. The dry film thickness at which cracking begins is the limit of the latex paint’s anti-drying shrinkage crack, called anti-drying shrinkage crack, and the unit is µm, as shown in Figure 6-7.

2. Requirements for anti-drying shrinkage cracks

For interior wall latex paint, the requirement for anti-drying shrinkage cracks is 400µm. For exterior wall latex paint, due to the poor flatness of the base layer, the requirement for anti-drying shrinkage cracks is increased to 900µm. This is Germany's anti-drying shrinkage cracking requirement for latex paint.

Since the coating film applied in my country is generally thinner than that in Germany, and the texture is not strong, the requirements for anti-drying shrinkage cracks can be appropriately relaxed. But for the latex paint applied on the relief paint, the requirement of anti-drying shrinkage cracks must not be relaxed, and it must be improved.

3. Causes of drying shrinkage cracks

Drying shrinkage cracks are caused by the drying shrinkage stress of the coating film being greater than its tensile strength. As the specific surface area of the mixture of pigments and fillers increases, the drying shrinkage stress of the coating film increases, and the possibility of drying shrinkage cracks increases. Insufficient amount of film-forming aids, too thick coating, uneven base, too fast drying, etc. may lead to drying shrinkage cracks.

4. How to improve the ability to resist drying shrinkage cracks

Due to the excessive drying shrinkage stress of the coating film, drying shrinkage cracks are caused. Therefore, all measures that can reduce the drying shrinkage stress of the coating film can improve the ability of latex paint to resist drying shrinkage cracks. Such as appropriately increasing the particle size of the filler, reducing its oil absorption, or increasing the amount of film-forming aids, using some fibrous or sheet-like fillers, etc.