1 Introduction

1 Introduction

The high-speed dispersing mixer is composed of a body, a dispersing stirring shaft, a dispersing disc or a dispersing paddle, a dispersing cylinder, a transmission system, etc. Figure 7-1 is a schematic diagram thereof. The body is usually stationary. There are fixed and liftable dispersing stirring shafts, as well as single-shaft and double-shaft. Small high-speed dispersing mixers generally use single shafts, and there are also biaxial ones, while medium and large high-speed dispersing mixers often use dual shafts. A typical dispersing disc is shown in Figure 7-2. In CHINA, most of the dispersing discs are made of steel, but abroad, discs made of engineering plastics are gradually increasing. The dispersion cylinder is a cylindrical container made of stainless steel, and the bottom should be dish-shaped or arc-shaped to prevent the formation of dead ends. Dispersion cylinders are divided into two types: fixed type and mobile type. The mobile type is used for small high-speed dispersing mixers, and some people call them cylinders. The fixed type is used for medium and large high-speed dispersing mixers with a volume of 10m³ or greater. The transmission system is divided into single speed, double speed and continuously variable speed. Single-speed can only be used for high-speed dispersion or stirring, while double-speed can be used for both high-speed dispersion and stirring. The stepless speed change is more flexible, it can be used for high-speed dispersion and stirring, and it can deal with various situations.

2. Advantages and disadvantages

The high-speed dispersing and stirring machine has the following advantages.

① Low investment, simple structure, convenient operation and easy maintenance.

②Double-speed and steplessly variable high-speed dispersing mixers carry out the processes of dispersing, blending and mixing in one machine, which simplifies the process flow.

③High efficiency, dispersing and stirring generally only need 10~20 minutes to complete, and the operation cost is low.

④Because of the simple structure, it is easy to clean.

Therefore, high-speed dispersing mixers are widely used in latex paint production.

Its disadvantages are low shear stress and weak grinding ability, so it is only suitable for pigments and fillers that are easier to disperse.

3. Selection

In latex paint production enterprises, high-speed dispersion mixer is a key equipment. Its capacity determines the size of the enterprise and the selection of other equipment. Therefore, the basis for the selection of high-speed dispersing mixer is the scale of the factory, taking into account other factors, such as color matching, batch size, capital, safety factor, etc.

4. Operation

In the production of latex paint, high-speed dispersing mixers are generally used for mixing, dispersing and paint mixing operations at the same time.

Add water first, and the amount of water is suitable to meet the solid content of 65%~70% during pulping, depending on the viscosity of the pigment and filler slurry. If the viscosity is too high, it is difficult to stir and disperse; if the viscosity is too low, the shear force is not enough, and it is difficult to disperse. Then add wetting dispersant, defoamer and thickener, etc., and mix evenly at low speed.

At an appropriate speed, add the pigments and fillers to the vortex, starting with the finer pigments and fillers, followed by the coarser ones. The so-called suitable speed is the speed that can bring the pigment and filler into the slurry quickly without bringing in air. With the addition of pigments and fillers, the viscosity increases, and the speed can also increase.

After adding pigments and fillers, increase the speed until the edge speed of the dispersing disc is 20~25m/s, and disperse for about 15 minutes at this high speed, depending on the fineness required. The rotational speed should not be too high to prevent the formation of turbulent flow and affect the dispersion. The dispersion time should not be too long, lest the temperature rise too high and reduce the dispersion efficiency. Then reduce the speed to complete the paint.

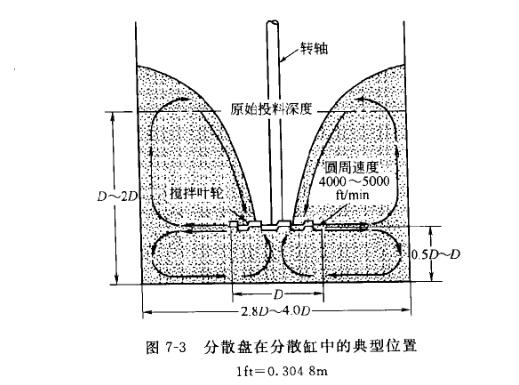

When the high-speed dispersing mixer is dispersing pigments and fillers, the typical position of the dispersing disc in the dispersing cylinder is shown in Figure 7-3. Dimensions in the figure are expressed in disc diameter. This given geometry is quite satisfactory in practical applications. In actual operation, due to the change in the actual number of people loaded, the dispersing disc also needs to be lifted up and down.

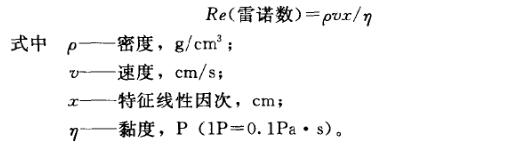

For the speed of high-speed dispersing mixer when dispersing pigments and fillers, because laminar flow is used for dispersion and turbulent flow is used for mixing, the flow of pigment and filler slurry generated by the rotating speed needs to be laminar flow. For flow in ducts and similar circular ducts, the critical Reynolds number is around 2000. When the Reynolds number is less than 2000, it is laminar flow; when it is greater than 2000, it turns into turbulent flow. The equation for the Reynolds number is as follows

In piping systems, the characteristic linear dimension is the pipe diameter. Some people think that for high-speed dispersing mixers, this characteristic linear factor is the distance from the bottom of the dispersing cylinder to the dispersing disc.

Assuming that the density of the pigment and filler slurry is 2g/cm³, the diameter of the dispersion disc is 33cm, the linear velocity of the dispersion disc is 2000cm/s (rotational speed is about 1160r/min), and the critical Reynolds number is about 2000, then the pigment and filler slurry The viscosity is at least 66P (6.6Pa·s). This also shows that when pulping, a higher solid content should be used and a thickener should be added at the same time.

1 Introduction

1 Introduction