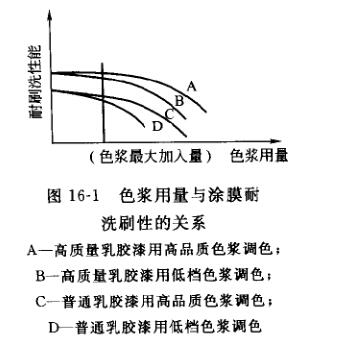

The use of high-performance colorants for coloring has little effect on the performance of latex paints when the maximum dosage is not exceeded. However, the use of low-grade color paste, or improper use of color paste may have a great negative impact on the performance of latex paint. The water resistance, scrub resistance, alkali resistance, gloss and other properties of the latex paint are reduced, and the original qualified base paint becomes an unqualified product after being formulated into a color paint. This relationship affects the scrubability.

The use of high-performance colorants for coloring has little effect on the performance of latex paints when the maximum dosage is not exceeded. However, the use of low-grade color paste, or improper use of color paste may have a great negative impact on the performance of latex paint. The water resistance, scrub resistance, alkali resistance, gloss and other properties of the latex paint are reduced, and the original qualified base paint becomes an unqualified product after being formulated into a color paint. This relationship affects the scrubability.

A - high-quality latex paint is toned with high-quality color; B - high-quality latex paint is toned with low-grade colorant; C - ordinary latex paint is toned with high-quality colorant;

A low-grade color paste for ordinary latex paint has a particularly serious impact on medium and low-grade latex paint. Figure 16-1 shows the effect of different quality color paste additions on the scrub resistance of different quality latex paints.

Low-grade colorants use a large amount of ethylene glycol as a humectant, which is highly hydrophilic. Ordinary latex paints use inexpensive wetting and dispersing agents to disperse and stabilize pigments. High-grade color paste uses propylene glycol as humectant and high-quality dispersant to disperse and stabilize pigments. Ethylene glycol has stronger water absorption than propylene glycol, and its volatilization rate is slow during the coating drying and film forming process, especially under low temperature and high humidity conditions. In addition, ethylene glycol is not environmentally friendly. Because the dispersion effect is not as good as that of high-crystalline dispersants, the dosage is relatively large, and wetting and dispersing agents have certain hydrophilicity, which will remain in the coating film for a long time, affecting the water resistance, scrub resistance and alkali resistance of the coating film. .

Another reason for the poor performance of the paint film is the improper selection of the base paint. As mentioned earlier, when white latex paint is used to adjust medium-color latex paint, or when translucent base paint is used to adjust dark-colored latex paint, the amount of color paste will increase exponentially. When the maximum addition of color paste is exceeded, the quality of the paint will be seriously affected, and the content of hydrophilic substances in the final coating film will be greatly increased, and the water resistance and scrub resistance of the coating film will be significantly reduced.

Solution: According to the depth of the required color, choose white latex paint, translucent base paint and varnish with different titanium dioxide content for color matching, and the amount of color paste should not exceed its maximum amount.