As a precision instrument for product color detection, the Colorimeter is also widely used in the determination of color gloss in the tobacco industry. According to the current international standards for flue-cured tobacco, when flue-cured tobacco is graded, it is first grouped and then graded. The color of the tobacco leaves is the same type of tobacco leaves.

For a long time, the evaluation of tobacco leaves at home and abroad has been through visual sensory evaluation, but because no one has a different degree of color recognition, it is affected by the environment, emotions and visual sensitivity. error. In my country's 42-level national flue-cured tobacco grading standard, there are no quantitative standards for the color and feature description of tobacco leaves, which also greatly affects the efficiency of tobacco leaf quality grading.

Based on the above situation, instrumental detection of tobacco leaf color has become a new need and a necessary method, using a Colorimeter to measure tobacco leaves. The color difference meter uses the photoelectric integration element with specific spectral sensitivity, and uses the international common color space CIE Lab to calculate the color difference information and color difference value. This method is not only scientific, fast and effective, but also gives information that is very accurate, clear and easy to analyze. . Using the internationally accepted CIELAB color space, the specific application of the Colorimeter in color detection in tobacco leaf grading was discussed. Thus promoting the development of tobacco leaf grading from traditional manual to instrumental, from qualitative to quantitative, from empirical to theoretical.

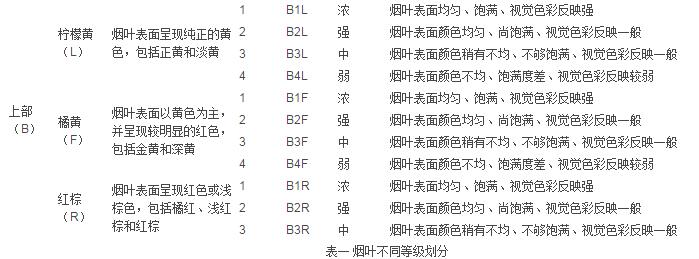

According to the standard samples formulated by GB2635-1992 flue-cured tobacco grading, tobacco leaves with upper lemon yellow (BL), upper orange (BF) and upper red brown (BR) were selected as research objects, that is, four grades of upper lemon yellow: B1L, B2L, B3L, B4L, 4 grades of orange on the upper part B1L, B2L, B3L, B4L, 3 grades of reddish brown on the upper part B1L, B2L, B3L, a total of 11 grades (see Table 1).

Among the samples of each grade, select 20 representative tobacco leaves (leaf surface is required to be flat), put them in a constant temperature and Humidity Chamber, set the relative humidity of the environment at 65%, the temperature (22±2) ℃, and the equilibration time is quite long In 24 hours; use the NH310 Colorimeter, select the color measuring diameter of 8mm, and under the condition of 8/d (8° illumination/diffuse light), firstly correct the black and white of the instrument, and then neutralize the leaf tip and leaf of each tobacco leaf. Take points at the base of the leaf for measurement; when measuring, put the tobacco leaves flat on the test bench with the front facing up to make them flatten naturally. The middle point with the edge of the leaf, try to avoid the lesions) Evenly select 3 points each, and measure 6 points on each tobacco leaf. The measured chromaticity indicators mainly include L* value (brightness value), a* value (red-green value, positive value represents redness, negative value represents greenness), b* value (yellow-blue value, positive value Represents yellowness, negative value represents blueness), C* value (saturation), h* value (hue angle) and ΔE value (total color difference value).

The color difference meter detects the color level of tobacco leaves not only quickly but also clearly and accurately, which can be said to be the product of the rapid development of science and technology. In such an era of informationization and digitization, the traditional visual estimation method cannot meet the requirements for color quality in more aspects. Therefore, the development of Colorimeters in all walks of life is an inevitable trend.

The above is the application of the Colorimeter in the detection of tobacco leaf color, hoping to provide reference for relevant personnel in the industry.