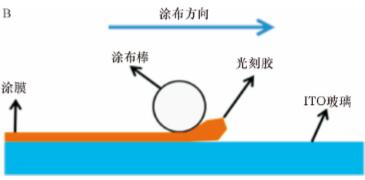

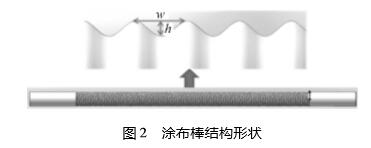

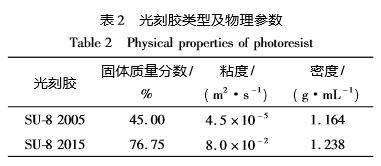

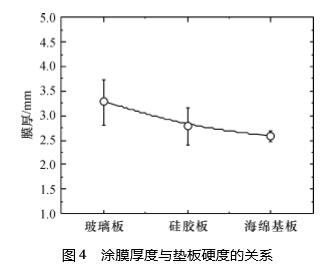

Several researchers from South CHINA Institute of Professional Optoelectronics and Color Dynamic Electronic Paper Display Technology Research Institute of South CHINA Normal University: Wei Biming, Jin Mingliang, Wu Hao, Dou Yingying, Zhou Guofu, Shui Lingling published a "big Research on Wire Bar Coating Process of Area Photoresist", which shows that high-viscosity coatings and large-area substrates can be coated by wire bar coating, and it is simple and effective.  It adopts OSP wire Bar Coater. It is found in the research of coating process that a more uniform coating film can be obtained by using a backing plate with low hardness (impression bed, north-south tide injection), and due to the support of the soft backing plate, the coating The film thickness is basically unchanged when the cloth speed is between 1.07~4.17cm/s and the backing plate height is between 5~40mm. The thickness of the coating film will vary with the viscosity of the photoresist and the size of the coating rod (North and South Chao Note: According to the introduction of the author's article, this size refers to the thickness of the wet film, that is, the larger the number of wire rods, the larger the film thickness , non-length or diameter issues) increase and thicken. In addition, the amount of glue drop has little effect on the thickness of the coating film.

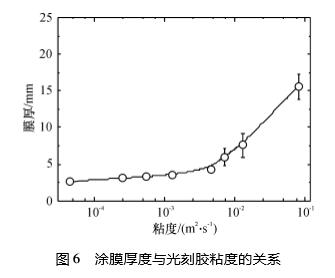

It adopts OSP wire Bar Coater. It is found in the research of coating process that a more uniform coating film can be obtained by using a backing plate with low hardness (impression bed, north-south tide injection), and due to the support of the soft backing plate, the coating The film thickness is basically unchanged when the cloth speed is between 1.07~4.17cm/s and the backing plate height is between 5~40mm. The thickness of the coating film will vary with the viscosity of the photoresist and the size of the coating rod (North and South Chao Note: According to the introduction of the author's article, this size refers to the thickness of the wet film, that is, the larger the number of wire rods, the larger the film thickness , non-length or diameter issues) increase and thicken. In addition, the amount of glue drop has little effect on the thickness of the coating film.

Studies have shown that softer pads, lower viscosity coatings and properly sized applicators are required to obtain a more uniform film. This aspect can also be confirmed by the procurement data of the Northern and Southern Tide. The use of RK impression bed has indeed been favored by more and more users who purchase coating rods.

According to the author's experience, the RK embossing bed is a hard polyester board + foam layer + rubber cushion, which is a more suitable coating platform for manual scraping. The reason is that the author uses a simple automatic film coating machine designed by himself, while the wire Bar Coater is mostly used for manual coating. Force and coating speed are subject to human interference. If the substrate is too soft, its force will be greatly affected, especially if there is a layer of covering power paper or tinplate on the coating film, the inclination or paper deformation caused by too soft is due to the uniformity of the coating film Adverse conditions.

【Original Download】

![]() Research on wire bar coating process of large area photoresist_Wei Biming.pdf

Research on wire bar coating process of large area photoresist_Wei Biming.pdf