DY-L series dyne pen can accurately test whether the surface tension of the plastic film reaches the value of the test pen. Let users know clearly whether the plastic film is suitable for printing, lamination or aluminizing. Effectively control quality and reduce tool delays caused by unqualified materials. And DY-L series dyne pens are not limited to plastic films, they can also test the surface tension of other flat materials.

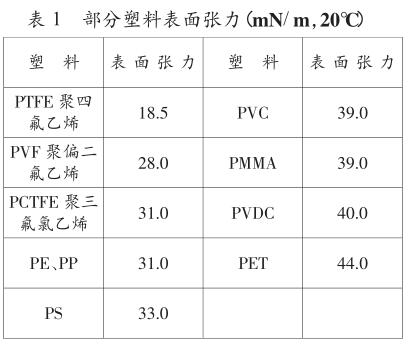

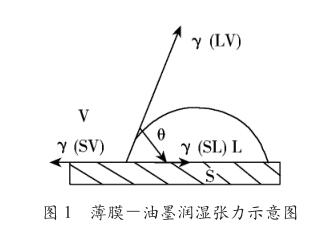

In general, thin film substrates are energy-dependent for the formation of ink droplets, coatings, and surfaces. If the energy at the surface of the substrate is lower than the surface tension of the applied test fluid, beading occurs and the drawing shrinks (as shown in Figure 1), which is called wetting. The original surface tension of most plastic substrates is relatively small, and the original surface tension of several polymers is roughly as follows:

The surface energy usually used as an ink solvent is: ethanol 22mN/m, ethyl acetate 24mN/m, and the preparation of ink needs to add resin, binder, pigment, and additives, and the surface tension is generally around 38-42 dynes . The value of the surface tension of the plastic is related to the molding temperature, cooling speed, additives and whether it is treated or not. Therefore, the BOPP film commonly used in color printing must be corona treated before printing so that the surface tension cannot be less than the surface tension of the ink, so as to achieve wetting. , as shown in Figure 1.

In the figure θ is the wetting angle. Obviously, when θ>90°, it is not wet due to the small wetting tension; when θ<90°, it is wet; and when θ=0°, it can be completely wetted. It can be seen that the surface tension of the film must be at least 38 dynes, so that the wetting angle between it and the ink is less than 90°, so that wetting can be achieved, so that the printing effect is better.

If the surface tension of the film is further increased, or if the surface tension of the ink is reduced, will the printing effect be better?

Can the so-called wetting angle be zero? To be precise, regardless of cost and physical feasibility, theoretically, such a little bit of ink will cover the entire film, and various colors will mix together, and the pattern will no longer be visible. up.

For most films, the surface tension of the film before printing requires a dyne pen between 36-40 dyne/cm. Nylon requires about 52 dyne/cm, and PET requires about 48 dyne/cm to be equipped with a dyne pen.

How to use: Make the DY-L dyne pen perpendicular to the plane of the film, apply appropriate pressure, and gently draw a line on the surface of the film (see Figure 2). Generally, three adjacent dyne pens are required.

analysis results

1. If the drawn lines are evenly distributed without any beads, it means that surface tension of the film is higher than the index marked on the Dyne pen, and it can be printed in this case.

2. If the drawn line shrinks slowly, it means that the surface tension slightly lower than the index marked on the Dyne pen. In this case, the printing effect is not good.

3. If the drawn line shrinks immediately and forms bead points, it means that the surface tension of the film is much lower than the index marked by the Dyne pen. This case cannot be printed.