1 Review and status quo of research and development of laboratory centrifuges in my country

(1) Laboratory centrifuges are necessary equipment for scientific research and production in biology, medicine, agronomy, bioengineering, biopharmaceutical and other industries. Relevant departments in our country have always attached great importance to the development of centrifuges. Centrifuges were once one of the 23 large-scale scientific instruments under the control of the State Science and Technology Commission, and were included in the national scientific and technological research projects twice.

CHINA's cumulative sum of funds and manpower investment in centrifuge research and development is the highest in the world. There have been some international good innovations in the field of laboratory centrifuges, especially ultra-high-speed centrifuges, but they have not been industrialized. At present, my country The development of high-end centrifuges is slow, and almost all rely on imports.

(2) At present, my country has gradually formed laboratory centrifuge production bases in Hunan, Shanghai and Beijing. CHINA established the laboratory centrifuge industry in the 1980s, which not only broke the monopoly of foreign countries, but also produced a wide range of low-speed centrifuges, high-speed refrigerated centrifuges and large-capacity centrifuges to meet market needs. Promote the development of related scientific research and industry.

(3) Under the huge impact of the market economy, the laboratory centrifuge industry

The industry ushered in a new period of rapid development. Due to the huge impact of the market economy, state-owned enterprises have been restructured and some have gone bankrupt. During this process, since the main technical force has not been lost, they can achieve faster development in the reorganization.

At the same time, after the reform and opening up, many foreign companies are optimistic about the Chinese market. Among them, France and Italy have established high-quality compressor units in Taicang, Jiangsu, and Japan has also established a variable frequency motor production base in CHINA. Composite materials for rotors have also begun mass production in CHINA. Therefore, in recent years, domestic laboratory centrifuges have begun to experiment with new localization and upgrading, including the development of self-developed desktop centrifuges.

2 Several major domestic laboratory centrifuges

At present, there are more than 110 centrifuge manufacturers in the country, and their products have developed into four series and more than 50 varieties. New combinations are bound to start. The living space of small enterprises will continue to shrink, and the emergence of large enterprises and groups will further promote the development of my country's centrifuge industry.

2.1 Super large capacity refrigerated centrifuge

Xiangyi introduced large-capacity refrigerated centrifuges from Beckman Company of the United States. After more than ten years of hard work, Xiangyi centrifuge has achieved independent innovation, and the capacity of a separable sample is twice that of Beckman's product. Multi-level shock absorption is adopted, the frequency conversion motor drive adopts professional vector technology, and the whole host adopts multiple protection measures. The microcomputer program controls the large-screen LCD display and the fluorine-free compressor unit. Its technical level has reached the world professional level of similar models. The products have been exported to the United States, Germany, Japan, Vietnam, Mexico and other countries. Centrifuge factories such as Yingtai and Pingfan also produce similar models.

The main technical parameters:

Model (Model): L720R-3;

Maximum speed (Maxspeed): 7200r/min;

Maximum relative centrifugal force (MaxRCF): 12166×g

Temperature setting range (Temperature range): -20 ~ +40 ℃;

Timing range (Timerange): 0~23h59min;

Speed accuracy (Speedaccuracy): ±50r/min.

2.2 High-speed refrigerated centrifuge

The high-speed refrigerated centrifuge introduced by Xiangyi from Japan's TOMY Company not only realizes localization, but also realizes independent innovation. The instrument adopts automatic rotor identification system, large-screen LCD display, independent setting of host and rotor operating parameters, automatic storage, automatic calculation of rotor service life, alarm and other protection functions, fluorine-free compressor, reaching the leading position of similar models International professional level. Intech, Pingfan and Hexi have produced the same type of centrifuges mentioned above.

The main technical parameters:

Maximum speed (Maxspeed): 25000r/min;

Maximum relative centrifugal force (MaxRCF): 64800×g (24×1.5/2ml25000r/min);

Maximum capacity (MaxCapacity): 4×1000ml;

Speed accuracy (Speedaccuracy): ±30r/min.

2.3 Desktop high-speed refrigerated centrifuge

Changsha Yingtai Instrument Co., Ltd., Changsha Pingfan Instrument Co., Ltd., Hunan Hexi Instrument Co., Ltd. and Xiangyi strive to develop desktop centrifuges, and independently develop new products of desktop refrigerated centrifuges. The desktop refrigerated centrifuge TGL20MC adopts frequency conversion motor, environmental protection fluorine-free compressor, automatic door lock and alarm system, multiple protection measures, 32-bit ARM microprocessor, large-screen LCD display, and CANRS-485 interface to realize computer and The centrifuge is networked and has the function of rotor identification. It adopts 32 sets of programs to store integral W2dt display control function and can perform step separation. In the rotation system, a spring cone is used to set and disassemble the rotor. The accuracy of the process can completely replace the imported high-end desktop centrifuges, which has brought my country's centrifuges to a new level and changed the long-term backwardness of my country's desktop centrifuges.

The main technical parameters:

Maximum speed (Maxspeed): 25000r/min;

Temperature range: -20~+40℃;

Temperature accuracy (Temperature accuracy): ±1.5°C;

Timing range (Timerange): 0~999min short-time centrifugation/continuous;

Maximum capacity (MaxCapacity): 6 x 1000ml (throw away the rotor);

Speed accuracy (Speedaccuracy): ±50r/min.

3 Technical level and gap of domestic leading products

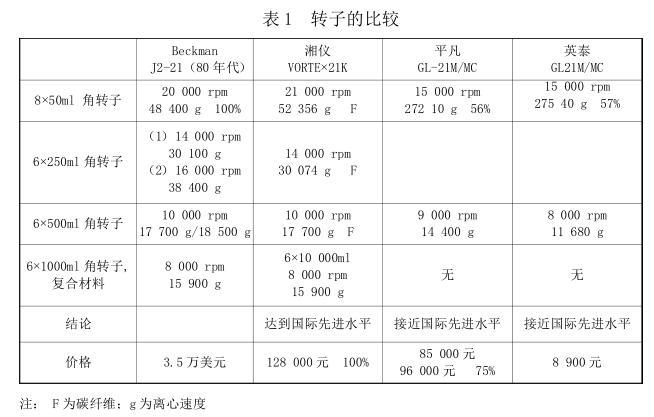

The gap between domestic products and international brands is mainly the quality and the highest index of the rotor, which require corresponding scientific and technological strength. 3.1 The index of a typical rotor of a classic high-speed refrigerated centrifuge is the key index of this centrifuge, and the comparative values of the rotors are shown in Table 1. my country's high-speed and low-speed centrifuge rotor technology is close to the world's professional level.

3.2 Comparison of rotor materials produced by domestic and foreign manufacturers

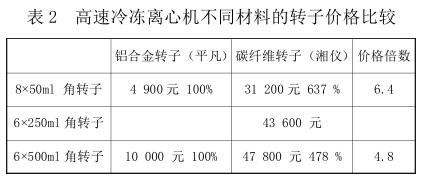

At present, the technical indicators and rotor safety performance indicators of domestically produced high-speed and low-speed centrifuge rotors have been met. Xiangyi has also developed a rotor made of carbon fiber materials. The destructive characteristics of rotors made of carbon fiber materials and other related safety studies have been conducted by Beckman Corporation of the United States. The technology is mature and it is known as a rotor that will not explode. The prices of rotors made of different materials are shown in Table 2.

目前差距是复合材料转头,无论品种、数量、价格无法满足国内需要,和国外专业水平还有较大差距。

3.3驱动部分的差距国内的企业大都采用变频电机直接驱动方式。控制系统稳定性的表现是故障少,并在逐年的积累中不断提高。

(1)差距

以英泰公司为例,有些转子的最大离心加速度尚差10%~15%,这点是我们完全可以补上的。对于那些对转子转速要求不太高的用户,国内产品可以满足需要。因此在这方面国内和世界专业水平没有太大的差距。

(2)优势

近几年,离心机的控制系统故障大幅度降低。由于离心机的设计从分立元件已过渡到集成电路,所以故障率已经相对减少。即使出故障,维修费用也比进口离心机少得多,而且维修速度快。因此,对此类品种,建议用户使用国内产品。

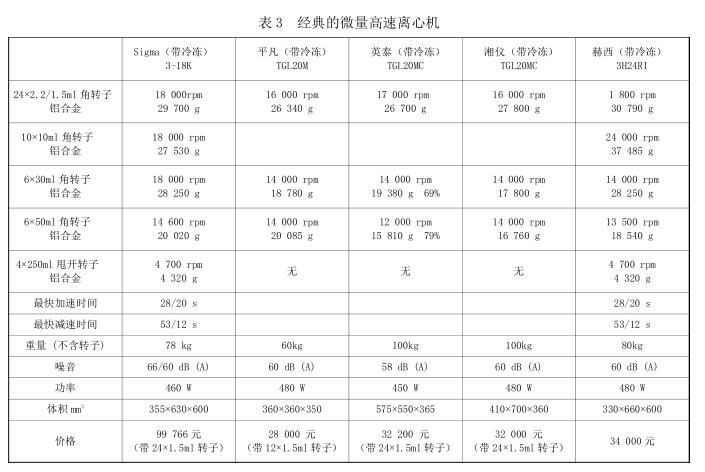

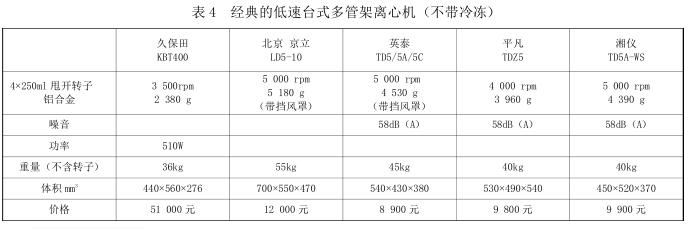

3.4国外和国内典型机型性

价比国内、外典型机型各参数对比如表3、表4所示。对于这类离心机,建议大家多用国产品。国产离心机已有40多年的历史,在产品性能、质量水平、维修服务等方面都有很大的优势。

3.5我国实验室离心机的科研水平

(1)核心技术与国际先进水平一致我国离心机关键技术研究取得了国际专业水平的成果,以下是与离心机的设计有直接关系的几项。

1)离心转子的机械安全设计

在国外文献的基础上结合国产材料的现状进行了转子的一系列机械安全性设计。为了转子在正常使用时不会“爆炸”,一要确定最高安全使用转速,二要确定在该最高转速下的允许使用时间或次数,即寿命。前者是确定允许的离心应力极限,后者是反复使用的疲劳极限。如果超过这两个极限中任何一个都很危险。

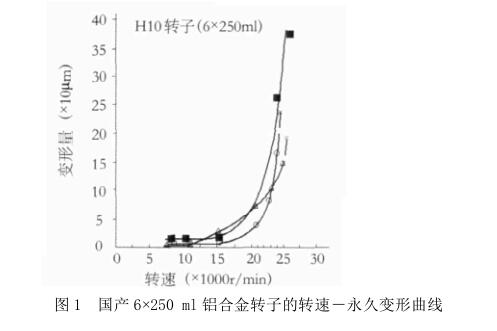

2)确定最高安全使用转速转子在受力时的变形行为与材料力学教科书中的长杆的拉伸与压缩不同要复杂得多,因此在理论指导下的实验工作是主要内容。以1980年实验的8种转子中的6×250ml铝转子为例,3个转子的长久变形拐点平均为15000r/min,“炸头”转速为约25000r/min,曲线如图1所示。由此确定最高安全使用转速为15000r/min。现在国外这种转子仍然以此为最高转速。当时使用的国产铝合金材料的性能和现在国际上使用的并没有多少区别,此类航空材料在国内外几十年前早已完善。该转子用LC4超硬铝合金锻造饼材,每个转子毛坯是单独的锻造饼材。生产厂家大都能严格按工艺要求进行,取得了一系列实验数据,所以目前国产离心机很少有“转子爆炸”事故发生。

3)确定疲劳寿命

当最高转速确定之后,还要确定最高转速在使用多少小时或多少次数内是安全的,即其使用寿命,主要是疲劳寿命。每种转子选3个,在比最高转速略高的转速时运转,以确保所得数据留有余地。在开发83000r/min国产钛合金转子时,当时国际上转子最高转速是日立公司的RP83T转子,83000r/min,以其约1.1倍的转速93000r/min旋转,运转一定次数后,测量长久变形。设计者要给出一个限度,比如10m,或80m等。长久不变形的材料是不存在的。而如果允许的变形过大,能保证的寿命则过短。在实验范围内,对日立公司RP83T转子进行了对比测量,结果显示国产转子优于日立转子。转子的安全性在90年代初超过日立公司,与当今国际水平持平。

离心机的机械安全设计中,还有其他一些内容,其中重要的是离心腔和盖的安全。离心机所配的几种转子中,最高转速转子发生“爆炸”时的危险不是较大的,这是因为它较小较轻,因此虽然转速较高,但转动惯量不是最大。在最高转速转动惯量最大的转子在其最高转速“爆炸”时威力最大。离心机的机械安全设计中的另一个内容就是转子在其最高转速“爆炸”时,碎片不得射出机外,盖也不得掀开。此数据也应在实验中确认。

(2)“九五”国家科技公关期间的成果国内关于离心机振动问题较深入的研究是在清华大学工程力学系,并与中国科学院生物物理所合作。研究课题是为提高离心机动力特性的设计水平,讨论典型离心机转子-支撑系统,进行动力特性计算。通过对转子-支撑系统的振型分析,明确各主要零部件对各阶临界转速的影响,并用实验验证计算结果,为离心机动力特性设计提供理论方法。转子温度智能补偿研究是创新的,在中科院生物物理所实验室里完成。3.6国际专业的技术—带断轴保险的离心机在国内的离心机事故中,还有在高速运转中断轴的事故。国产的和国外的离心机都发生过此类事故。打开断轴离心机盖子,可看到主轴已断,转子横躺在离心腔中,有时转子和转子盖已分开,且外边缘已被磨亮。显然,事故发生时若有人在旁,会发生人身事故。要分离的样品都撒在离心腔里,样品血本无归,还污染离心机。

笔者第一次设计了带断轴保险的离心机主轴系统。这里,把主轴的支承转子和传递扭矩的功能分开。这样,一旦发生断轴事故时,扭矩不能再带动转子,转子在摩擦力作用下逐步停转,但仍在自身的安装位置上,因此有效根除了过去因“断轴事故”所带来的那种灾难。该设计曾应用在高速冷冻离心机(1980年,图们)和低速大容量离心机上(“九五”国家科技攻关课题,1997年),而后者曾出过产品。

4发展方向和解决措施

(1) Establish the third ultracentrifuge manufacturer in the world At present, in the Chinese market, Chinese products account for more than half of the low-end product market, which can completely replace imported products, but the market share of high-end products is very small, and the ultracentrifuge market share is almost zero. Our country has the ability to select and integrate excellent scientific research to form a new enterprise. It will be a base integrating scientific research, production and personnel training, and produce a full range of centrifuges including ultra-speed centrifuges. machines and related instruments. It will be the third ultracentrifuge manufacturer in the world, and CHINA will become the third ultracentrifuge producer in the world and will gradually export.

(2) Restoration of industry associations and rectification of market order The restoration of the Laboratory Instrument Branch of the CHINA Instrument and Meter Industry Association is a good thing that everyone has been looking forward to for many years. It is hoped that it will play its due role in the rectification of market order and the construction of a fair market environment. . Industry associations to call for a boycott of bidding misconduct.

(3) Strengthen investment in scientific research projects and personnel training of ultracentrifuges. It is hoped that CHINA's ultracentrifuges will have greater development within 3 to 5 years. Strong support from relevant national departments and localities is needed, and national projects can be adopted to drive this process. But more importantly, there must be a leading unit or personnel, which requires the active response of relevant enterprises. At present, there is no postgraduate training for the centrifuge major in our country, and there is no corresponding research on scientific research topics. However, most of the originally trained researchers "go to the sea" and the research group does not exist, which greatly affects the sustainable development ability of our country. Therefore, it is urgent to strengthen the training of senior talents in centrifuge.