In order to establish a technical support system for the standard operation and maintenance of laboratory centrifuges, explore the relationship between the correct selection of various centrifugal technologies and centrifugal rotors and accessories; analyze the application of common centrifugal parameters such as RCF, RPM, S value, and K-value. Conditions and calculation methods, functional configuration Evaluate the rationality of centrifuge rotors, adapters and centrifuge containers, reasonably select and perform pretreatment according to the physical and chemical tolerance of centrifuge container materials, formulate risk control-based operation, monitoring, maintenance, maintenance, biological Security and other technical guarantee paths. Adhere to the full technical process management from experimental application to engineering maintenance, and implement the full technical path specification management of centrifuge use and maintenance, which effectively guarantees the normal use of laboratory centrifuges.

0 Preface

Centrifugation is the use of the centrifuge to drive the centrifugal force and the difference in the sedimentation coefficient or buoyant density of the centrifuged sample material to complete the separation, concentration, extraction preparation, analysis and determination of the molecular weight and purity of biomolecules. It is a routine experimental technology, and its application covers life science, material science and other related professional experiments [1-3]. Therefore, in order to effectively play the role of centrifuges in scientific experimental research and technological innovation, it is necessary to study the interaction between centrifugal force and centrifuged samples, and standardize the technical path of operation and maintenance.

1 Selection and application of centrifugal technology

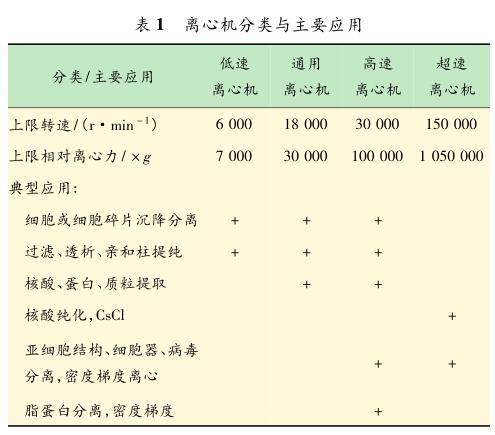

Based on relevant literature reports [4-6], according to the upper limit of the relative centrifugal force (Relative Centrifugal Force, RCF) of the centrifuge and its main application, the centrifuges commonly used in the laboratory can be roughly divided into 4 categories, as shown in Table 1.

(1) Centrifugal speed. The speed at which the rotor rotates driven by the centrifugal drive system , in r/min.

(2) Relative centrifugal force. When an object moves , a centrifugal force F=ω2r will be generated, but the centrifugal force must overcome the influence of the vertical gravity of the earth and the friction and buoyancy of the sample particles (the latter two can be ignored), so it is represented by RCF, RCF =ω2r/980, equal to the centrifugal force acting on the sample particles in the centrifugal field is equivalent to the multiple of the earth's gravity, the unit is the gravitational acceleration g, RCF=1000g is 1000 times the gravitational acceleration. The size of RCF is related to the centrifugal speed and the path (actual centrifugal radius) of the particles from the spindle in the centrifuge container, that is, RCF=1.12r(n/1000)2, so there are maximum, average and minimum RCF. Whether the sample particles can be effectively separated mainly depends on the RCF, and the maximum or average RCF is often given as the centrifugation condition in the literature. The RCF corresponding to the rated speed of the rotor can be converted through the centrifugal radius-RCF-RPM curve, but it is recommended to check the manufacturer's rotor parameter table for the exact RCF value.

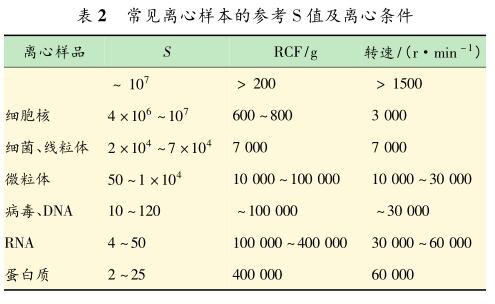

(3) Sedimentation coefficient S. It is an important physical and chemical parameter [7]. The Svedbergs value (S value = 10-13s) represents the sedimentation rate of the sample particles corresponding to the centrifugal force, and the centrifugation time (completely settled to the bottom of the container) of the sample particles with different S values The expression is t=1/Sω2·ln(rmax/rmin). See Table 2 for the S values and reference centrifuge strips of common isolated biological samples

(4) K factor value. Reflects the efficiency of the centrifugal rotor, related to its size, material and speed. The settling time of sample particles with a certain S value can be estimated by using the K value: t=K/S; the smaller the K value, the higher the centrifugal efficiency of the rotor and the shorter the time required for particle settling [8].

1.2 Centrifugal technology

According to the interaction mode between the centrifugal force and the centrifuged material, it can be divided into differential centrifugation and density gradient centrifugation.

1.2.1 Differential speed centrifugal

Differential speed centrifugation uses the difference in sedimentation velocity of particles with different sedimentation coefficients in the centrifuged sample components (such as various cell components), and is separated by successive sedimentation after a certain speed, a certain centrifugal force and a certain time of centrifugation. During this process, samples are often separated into two parts: sediment and supernatant. The premise is that the difference between the S values of two or several particles to be separated is large enough (at least 10 times the difference) to obtain better separation. If the difference between the S values of two or several particles is small, it is difficult to obtain good separation. The key is to accurately control the time and speed of step-by-step centrifugation. If the time is too long or the rotation speed is too high, the particles that should not settle will also settle down, affecting the separation and purification effect [9].

1.2.2 Density gradient centrifugation

Density gradient centrifugation is the centrifugal sedimentation or sedimentation equilibrium of the sample in an inert medium liquid with a density gradient, that is, the particles are distributed to the corresponding positions in the gradient liquid under a certain centrifugal force, and different zones are formed to obtain separation [10] . Density gradient centrifugation can be further divided into:

(1) Density gradient sedimentation centrifugation or differential zonal centrifugation. It is used to separate samples with different particle sizes and shapes (there is a certain difference in S value) and similar density. Gradient liquid density < sample component density, first add the sample liquid on the gradient liquid surface, under the action of centrifugal force, the particles settle at a certain speed and gradually separate in the centrifuge container to form a zone from bottom to top according to the sedimentation coefficient. The main point of operation is to set the centrifugation time accurately (the machine will stop after the maximum distance between the sample zones), and the speed reduction should not be too fast.

(2) Isopycnic centrifugation. The particles of the sample to be separated are within the density range of the density gradient liquid , and they are uniformly distributed in the sample added before centrifugation. Under the action of centrifugal force, according to the difference in buoyancy density of different particles, they either settle down or float up, and finally move along the gradient to Zones are formed at the positions of density gradients that are exactly equal to them (that is, isodensity points). The centrifugation effect depends on the difference of the buoyancy density of the particles. The larger the difference, the better the separation effect. It has nothing to do with the size and shape of the particles, but the latter two involve the equilibrium speed, time and width of the zone. Centrifugation time is generally longer than differential zonal centrifugation.

1.3 Selection of centrifugal rotor

Laboratory centrifuges are usually configured with fixed angle and horizontal rotors.

Other manufacturers can also provide drum rotors, cytocentrifuge smear devices, etc.; high-speed and above centrifuges can be equipped with vertical, near-vertical, and zonal rotors.

选择转头主要According to实验室的功能定位及其对离心技术的需求[11-12],3种主要离心技术转头选择见表3。1.3.1离心条件的转换计算当离心技术确定之后,完成某种样品的有效离心分离,常关注的离心参数是S值、RCF、离心时间。多数情况下,这些参数主要从文献中获得。存在的问题是,文献上给出的离心条件往往与所在实验室可利用离心机的性能有一定差异,如何将文献离心条件转化在本实验室离心机上使用,常用计算方法如下。

在给出T1和RCF1的情况下,According to实验室现有离心转头RCF2转换所需T2:T2=T1×RCF1/RCF2;

在给出T1和K1的情况下,According to实验室现有离心转头K2转换所需T2:T2=T1×K1/K2。获得精准计算,一定要建档管理离心机使用说明书、使用记录等技术资料[13],随时可调用参考。另转换范围控制在20%为宜,不能偏离过大,因为没有足够的离心力即便是延长离心时间也无意义。

1.3.2离心容器的选择

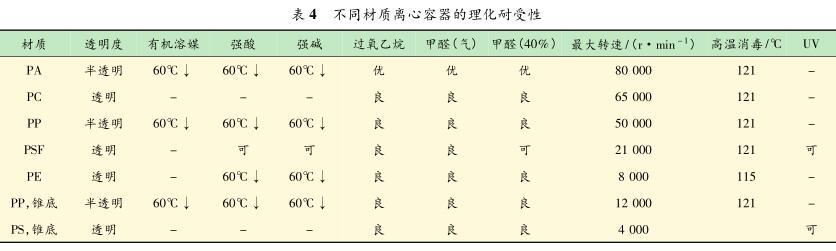

除要考虑离心容器的式样、容量外,常被忽略的是容器的物理及化学耐受性,材质不同的塑料离心管物理和化学耐受性各异,常发生由于错选材质而导致容器溶裂、破损,有机溶剂溅出腐蚀仪器事件。常用离心容器材质为多聚物(Polyallomer,PA)、聚碳酸酯(Polycarbonate,PC)、聚丙烯(Polypropylene,PP)、聚砜(Polysulfone,PSF)、聚乙烯(Polyethylene,PE)和聚苯乙烯-Polystyrene(PS),其理化耐受性见表4。

1.4主要操作注意事项

离心机的应用存在着一定的风险,应把风险评估理念贯穿与离心过程、规范操作。

(1)必要的检查与测试。检查离心容器与离心转头孔位或套筒适配性,在高速离心时,必保证离心容器与离心转头孔位适形,特别是在使用锥形底管的情况下,避免在强离心力作用下管底堆陷。

检查离心转头(特别是高速以上转头)的外观有否划痕或裂纹,According to情况决定是否停用或减速使用(至少减速额定转数的10%)。

定期核查对超速离心机驱动系统及其转头的累计使用时间,一旦超过生产厂给定的保证期要做出减速评估[14]。超速离心机的使用者要经过培训[15]、考核取得资质后方可上岗操作,更好安排专门人员负责。

检查真空泵的油水平和实际真空度;如真空路径装有HEPA滤器,要复核其使用时间。

检查离心舱内及转头或离心容器适配器件内有否离心容器碎片、残留水等异物,并清除之;复核转头和水平转头的离心(吊)桶是否安放到位。

检查离心容器有否变形、裂纹、损伤或老化现象,擦干离心容器外壁上的水迹。

检查离心容器加样量,一般原则是无盖容器不要装得过满,以免离心甩出;而在高速或超速离心时使用带有密封器件或压封盖的容器时,则常要求装满以避免在离心力作用下造成变形陷裂。可参考生产厂提供的转头及容器手册,会标明不同形状、材质离心容器在不同转速时额定加样量。

(2)离心配平。离心配平是指离心转头及吊桶的管位几何学对称重量平衡,乃至转头整体平衡,保证转头负载分布均匀;不要采取容量配平(特别是在高速以上离心),因为离心容器、加样器等会存在偏差。

检查离心转头及离心吊桶管位内有否残留有容器碎片或液体(制冷离心后,放置一定时间也可能出冷凝水),要排除这些潜在的不平衡因素。

检查水平头安装的吊桶自重是否对应配平,生产厂会在吊桶上标记重量;当装载不同容量样本一起离心时,尽量避免使用两对自重差别较大的管架。

近代离心机多装有失平衡保护功能,要严格控制偏差在额定重量以内;但良好选择是坚持在天平上精密完成一对一配平操作,避免离心驱动系统常在不平衡调整状态运行。在吊桶或管架中放置多管离心时,建议要连同吊桶或管架一起完成配平。

(3)预冷。预冷系指离心转头及其装载附件和离心舱的预冷。更好将转头先放在冰箱或冷室,进而保证转头整体预冷。离心舱和小体积转头的预冷,可以在离心前,设置欲控制温度在1000~2000r/min运转10~20min(视室温),或使用离心机预冷程序。对大体积转头,建议事先放置在冷室或冰箱内预冷。

(4)其他。启动离心机后不能随即离开实验室,要监测运行到设定转速且平稳、无任何异常声响后方可。但使用高速、超速离心机时,建议要在位密切监测仪器运行状况。

如开启离心舱盖后转头还在余转,禁忌用手制停。

对疑有生物污染的样品,应在生物安全柜中上样,离心后也要在生物安全柜中静置待气溶胶下落后方可打开转头密封盖取样,BSL3级及以上实验室内的离心操作应参照有关生物安全操作指南[16]。

2离心机常规维护

2.1定位与调平确认安装是离心机维护与保养的基础步骤,仪器操作负责人应参加安装全过程。移动离心机位置安装后,要注意以下事项:

(1)离心机的安装位要避开阳光直晒、灰尘、通风不良、热辐射、过度振动、存在腐蚀性化学物质、洗刷池等[17];附近不应放置天平、光度计、显微镜等精密仪器。

(2)移动冷冻离心机到位后,要静置60min或更长时间(视搬运的剧烈程度)后方可开机。

(3)电源。首先要确认仪器工作电压、电流、频率、相位等技术参数,连接电源应满足仪器最大启动功率要求的115%,需要有接地[18],功耗较大的落地式高速机及超速机应另单独安装气动开关。

(4)台式离心机。安放的实验台要平整、结实、无晃动,离心机的支脚更好能与实验台的支撑柱对应;距墙壁或周边设施至少20cm,有条件的情况下可再宽余些空间,便于散热、维护和检修仪器。

(5)落地式机型。首先要评估地面或楼板的承重能力,选择在墙侧为宜;其他同台式机。

(6)使用经校准的水平测具置于离心中轴位测量360°方位的水平状况,进行离心机定位水平调整。

2.2提示维护保养措施

(1)离心舱。用软布擦拭清理离心舱,除去残留物,但注意不要伤及温度传感器;制冷离心化水后要及时擦干,保持开舱盖晾干后再关上;离心舱密封胶圈不能用有机溶剂擦拭,真空不足时要检查胶圈是否有污物或老化;发现舱壁有锈蚀,尽快采取除锈处理。

(2)使用较频繁的低速及通用离心机离心机,要定期卸下转头,清理轴杆;用毛刷清理离心轴杆的螺旋缝隙,涂润滑膏,以免垢污填塞,反复旋拧损伤螺口。停用间期,要卸下转头进行保养。

(3)离心转头。用软木棒缠绑软布或脱脂棉擦拭清理转头或管架孔位,制冷离心后要及时清除水迹。用毛刷清理转头与驱动轴拧固处的螺旋缝隙,并涂润滑膏。

(4)用软布擦去水平转头与吊桶悬挂位的污垢,涂润滑膏。

(5)检查转头、离心吊桶的密封胶圈有否老化、变形、断裂等现象,及时更换。

(6) Keep the centrifugal laboratory clean; regularly remove the dust from the cooling , especially the compressor.

(7) If the centrifuge is stopped for more than 1 month, it should be turned on and the rotor should be turned on to observe whether there is any abnormal sound and whether it can reach the rated indicators such as speed and refrigeration temperature. Rotors that have not been used for a long time should be cleaned and coated with protective agent.

(8) Check whether the centrifuge power plug and connecting socket are in poor contact or burnt, whether the power cord is aging, and deal with any problems in time.

(9) Regularly check the connection status of the vacuum pipeline and related facilities, and whether the filter is blocked.

(10) The stains on the surface of the chassis can only be cleaned with a soft cloth dipped in water or a near- neutral and non-abrasive detergent. It is forbidden to wipe the display panel and the observation window above the hatch with a dry coarse cloth or organic solvent.

3 Epilogue

Standardized use and necessary monitoring and maintenance measures are important guarantees for improving the technical efficiency of centrifuges, and every technical path must not be ignored. While implementing the centrifuge application technology guarantee system, the laboratory has strengthened the technical training for experimenters and offered elective courses for graduate students. In the past 5 years, the centrifuge failure rate has gradually decreased, and basically no paid maintenance has occurred, providing effective technical services for the school's scientific experimental research, experimental teaching, and shared services in the region.