Paint inspection is an important means to judge the quality of paint, and how to correctly adopt and implement technical standards in the inspection directly affects the measurement results.

The technical standards of my country's coating industry are relatively complete, and the testing method standards almost cover coatings, coating films and their performance. The correct adoption and implementation of these technical standards in coating testing can not only ensure the accuracy of test results, but also provide support for research and development, production, The use of correct and effective data will also promote the healthy and standardized development of the coatings industry.

Since the 1980s, the testing method standards in the national standards have been gradually in line with international standards. The coating testing method standards were confirmed in 1989, and the original mandatory standards were generally changed to advisory standards, which reserved a large choice for standard selection. It also puts forward higher adaptability requirements for the implementation of standards. In practical activities, only when the standards are fully understood, carefully selected and strictly implemented, can the technical standards play their normative, supporting, guiding and supervisory roles.

The following is a discussion on how to correctly collect and implement standards in several links of paint testing, such as sampling, paint film preparation, state adjustment, and testing.

1 sampling

GB3186-l982 (l988) "Sampling of paint products" is one of the few mandatory standards in paint testing standards, which shows the importance of sampling for testing.

The key to sampling is to ensure the representativeness of the sample, that is to say, only a representative sample can detect the correct result. GB3186 has made regulations on the sampling of different forms of paint products, and the importance of which needs no repeating is the sampling location and the number of samples taken.

Under the condition of sufficient mixing, the sampling site should be taken from the upper, middle and lower layers. The number of samples to be taken is determined according to the number of barrels submitted for inspection (n), and the standard stipulates that it should not be less than, /j, that is, samples should be taken from the number of barrels greater than or equal to f, and the sample size should meet the needs of the test items and the need to store samples for future reference , and take enough at once.

In the actual production and acceptance, there are many cases where sampling is not paid much attention to, and there is a lot of randomness. Not only do we not take samples according to the location and quantity, but we also do different testing items and provide different samples. All testing items of coatings cannot be guaranteed from the same Obtained from samples, leading to increased uncertainty in the results.

2 paint film preparation

Paint film preparation is the first process of paint film performance testing, which is to prepare paint film on the standard test panel specified by the product (see GB/T927l-1988).

The commonly used national standards for paint film preparation are: GB/T1727-1992 "General Preparation Method of Paint Film", GB/T1765-1979 (1989) "Preparation Method of Paint Film for Determination of Humidity and Heat Resistance, Salt Spray Resistance and Weather Resistance (Artificial Acceleration) », GB/T6741-1986 "Uniform paint film preparation method (rotary paint device method)"

And GB/Tl736-1979 (1989) "preparation method of insulating paint film", HG/T3334 "preparation method of electrophoretic paint film", etc. The scope of application of the above-mentioned standards is different. Except that GB/T1736 and HG/'T3334 are respectively applicable to insulating paint and electrophoretic paint, the application scope of the other three standards must be strictly distinguished. The paint film prepared according to the provisions of GB/T1727 is used for the detection of general properties; the paint film prepared according to GB/T1765 is used for the determination of specific properties. The paint film preparation specified in GB/T16741 is one of the general paint film preparation methods, and is more used for referee testing. In addition to the clear regulations on the substrate, substrate surface treatment, coating method, curing conditions, etc., another important feature is often ignored in the preparation of paint film, which is thickness. Because the thickness of the paint film has a great influence on the test results, the prepared paint film can only be used for the test if it meets the specified thickness. The test report shall indicate the range of paint film thickness while reporting the test results.

A common irregularity is that the thickness of the paint film for mechanical properties such as impact resistance, adhesion, and flexibility is ultra-thin, while the coating is ultra-thick for weather resistance tests, so that the test results are likely to pass, but it is easy to lose the truth. and comparability. In common test reports, the corresponding part only gives the test results, but does not report the paint film thickness, so it is impossible to determine the thickness under which the test results were obtained.

3 state regulation

State regulation standards are mandatory standards.

State conditioning refers to the operation process in which the sample or test piece should be placed under the specified environmental conditions and kept for a predetermined time before the paint film test. This link has a great influence on the test results, but it is often neglected. The standard environmental conditions given by GB9278-l988 are: temperature (23i2)°C, relative humidity (50±5)% or (23±2)°C ambient humidity.

Condition adjustment is an important part of paint film preparation, so the expected time is specified in the corresponding paint film preparation method standards. According to GB/Tl727 for the preparation of paint film for general performance test, self-drying paint and drying paint are adjusted for 48h and 24h respectively, and then various performance tests are carried out; according to GB/Tl765 for performance test of paint film, self-drying paint And the adjustment time of drying paint state is 7 days and 1 day respectively.

4 Test environment

It mainly refers to the temperature and humidity environment of the test. Some testing items have very strict requirements on environmental conditions, such as paint viscosity. For the environmental conditions of the performance test of the paint film, except that the test method standard has clear provisions, the temperature and humidity of the test are the same as the state regulation in accordance with the provisions of CB9278. In the actual For non-arbitration purpose tests, the ambient temperature and humidity can be carried out under non-standard conditions, but the actual temperature and humidity range of the test environment should be indicated in the test report.

5 detection

The technical contents such as paint testing methods, data processing, and result judgment are all reflected in the corresponding testing method standards, and by strictly implementing the provisions of these standards, reliable results can be obtained. In the current technical standards, there are several method standards for many testing items at the same time. It is necessary to pay full attention to their scope of application in standard adoption and implementation to prevent misuse. The following discusses the standard selection of several common testing items.

5.1 Determination of paint film thickness

Commonly used standards for the determination of paint film thickness include GB/T1764-1979 (1989) "Determination of Paint Film Thickness", GB/T13452.2-1992 "Determination of Paint Film Thickness of Paints and Varnishes", the former comes from the standard conversion of the Ministry of Chemical Industry , the method is intuitive and simple; the latter is equivalent to ISO2808, although it does not include all the general methods of thickness measurement, but it gives a variety of applicable methods for the measurement of paint film thickness under different conditions, such as hard film, soft film , wet film, magnetic substrate, non-magnetic substrate, etc., the scope of application is accurately defined, and the technical approach for determination is also broader. In addition, there are GB/T4956 and GB/T14957. The former specifies the measurement of the thickness of the non-magnetic coating on the magnetic metal substrate - a magnetic method, and the latter specifies the measurement of the thickness of the non-conductive coating on the non-magnetic substrate - the eddy current method. , These two standards are actually the expansion and broadening of the relevant methods of GB/Tl3452.2, and the measurement principles based on them are roughly the same, except that their measurement objects are not limited to paint films. It is also applicable to ceramics, glazed porcelain, some chemical conversion coatings, etc. It should be specially reminded that the eddy current method cannot be used for coatings containing metal pigments and fillers, because the eddy current generated by the metal powder will affect the test results.

There are many methods involved in the above-mentioned standards, and the applicable conditions are different, so we should pay attention to distinguishing them when adopting and implementing the standards.

5.2 Determination of coating fineness

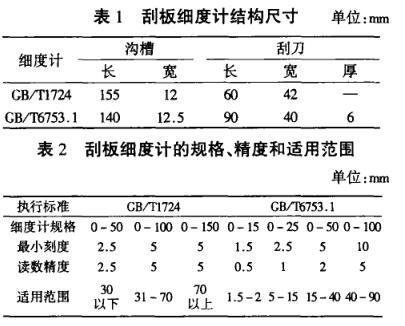

The most common and convenient way to measure the fineness of paint is the scraper Fineness Meter method. The two standards GB/T1724 "Determination of Coating Fineness" and GB/T6753.1 "Determination of Coating Grinding Fineness" both use the scraper Fineness Meter as the measurement tool, but its structure, graduation value, and measurement accuracy Judgment standards and applicable fineness ranges are different. Table 1 lists the size differences of the scraper fineness gauges of these two standards, and Table 2 lists the applicable standards of the two standards.

Two standard fineness gauges, even though the minimum scale is the same, but the reading accuracy is different, the reason is that the two standard fineness judgment methods are different. In the actual measurement, it is necessary to strictly distinguish between the two standard scraper Fineness Meters, and to correctly implement the scope of application and the judgment rules to obtain correct results, and must not be mixed.

5.3 Determination of paint film adhesion

GB/T5210 "Coating Adhesion Determination Method Pull-off Method" can quantitatively measure the adhesion, but the test procedure is complicated, especially the test preparation workload is relatively large. Generally, less is used. It is used when it is inconvenient to measure other methods (such as ultra-thick coating) or when definite mechanical data is required. Both GB/T1720 "Determination of Paint Film Adhesion" and GB/T9286 "Varnish and Paint Film Cross-cut Test" can only obtain qualitative adhesion levels. GB/T1720, that is, the circle method, has been used for a long time in the determination of paint adhesion in my country and has a wide range of applications. GB/T9286, that is, the cross-cut method can be carried out directly on the coated product, and at the same time, three grades of 0, 1, and 2 are given as passing grades. Therefore, the use of this method in the testing of coating products is on the rise. The definition in the scope chapter of the standard is often ignored, that is, "this test procedure cannot be regarded as a method of adhesion determination", and the items listed in Appendix A of the standard should be provided to make the test procedure available. material.

Regardless of the scratch-grid method or the scratch-circle method, for coatings containing flaky metal pigments and fillers such as flake aluminum powder and zinc powder, the test results may be affected by the phenomenon of "crushing powder". .

The author tested these two methods on the same sample t with different coatings, and the results are shown in Table 3.

It can be seen that for the paint with higher hardness and better adhesion, the results measured by the two methods are all very good levels. For the paint with lower hardness and weaker adhesion, there is a big difference in the grades measured by the two methods.

5.4 Determination of electrophoretic paint penetration

The measurement of electrophoretic paint penetration has not yet formed a national standard. The FAW steel pipe method was widely used earlier in the industry. In the late 1970s, the Ministry of Chemical Industry formulated two standards, HG/T3336 and HG/T3339, which are called glass tube method and steel pipe method respectively. These two standards are based on the anodic electrophoretic paint. Although they can also be used in the cathodic electrophoretic paint, it is almost impossible to judge the performance difference of the electrophoretic paint with high throwing power, because the result may show 100% throwing through. Therefore, the current domestic automobile industry recommends using the Ford box method for cathodic electrophoretic paint with high throwing power (see Issue 6, 2005 of this magazine for details).

6 Epilogue

The above discusses some experiences and understandings of standards collection and implementation from the aspects of paint testing, and shows that carefully distinguishing the characteristics and adaptability of various technical standards is a problem worthy of great attention in paint testing. Only by carefully digesting the technical standards, correctly selecting the standards, and strictly implementing the standards, can we ensure that the coating performance testing is standardized and accurate, and the confidence level can be steadily improved.