A gear pump is a tool used to transport trace amounts of liquid, and it is a small rotary positive displacement pump. It consists of two closed spaces consisting of two gears, the pump body and the front and rear covers. When the gears rotate, the volume of the space on the side where the gears are disengaged increases from small to large, forming a vacuum to suck the liquid, and the volume of the space on the meshing side of the gears increases from small to large. The big becomes small, and the liquid is squeezed into the pipeline.

The micro ring gear pump imported from Germany is suitable for occasions with small volume or fast flow rate and high measurement accuracy, including mechanical engineering construction, such as analytical instruments, chemical process technology, pharmaceutical production, biotechnology, fuel cell and energy technology, aviation and other fields .

So many people may not know much about the technical principle of the ring gear pump, let's learn more about it.

Technical principle of micro annular gear pump

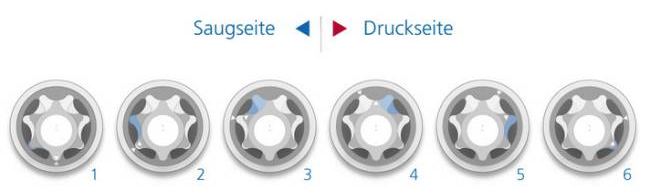

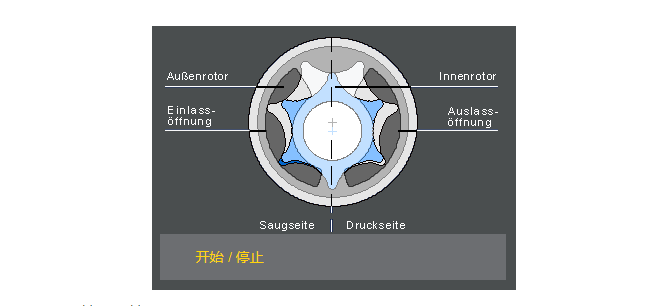

The two eccentric wheels of the micro-ring gear pump are meshed by the cycloidal pinwheel when rotating, so as to ensure that the system has several sealed pump chambers at any time. The size ratio of the meshing teeth is roughly 6/7, which can produce 6 Sealed pump chamber.

The shaft of the Micro Ring Gear Pump is connected to an internal rotor powered by a precisely controlled electric motor. The outer rotor mounts a rotatable base and is driven by the inner rotor.

With the rotation of the eccentric shaft rotor, the pump chamber space on the feed side increases and the pump chamber space on the discharge side decreases, and thus produces a homogeneous and low-pulsation flow, at the same time several identical pump chambers are produced , During operation, the delivery direction of the pump is reversible.