At present, most domestic units use the ZBD Whiteness Meter manufactured by Wenzhou Instrument Factory to test the whiteness of silk fabrics. The instrument uses a 457nm violet beam to project onto the sample surface at an incident angle of 45°, and then uses a selenium photocell to receive the diffuse scattered light reflected from the sample surface in the direction perpendicular to the sample surface. The whiter the sample, the greater the luminous flux of the diffusely scattered light received by the selenium photocell, and the greater the output photocurrent. Therefore, the whiteness of the sample can be expressed by the magnitude of the photocurrent. Ordinary refined white silk fabrics have different degrees of yellow light. Because yellow and blue are complementary colors. Therefore, when the purple-blue light is irradiated on the surface of the white silk fabric with yellow light, the sample can obviously absorb the purple-blue light, thereby reducing the reflectivity of the purple-blue light, that is, reducing the whiteness value of the sample. . For this reason, it is more sensitive to use the purple-blue beam as the light source to measure the whiteness of the refined white silk fabric with yellow light.

When using the domestic ZBD Whiteness Meter to measure the whiteness of silk fabrics, in order to obtain more accurate measurement values and better repeatability, so that the test data can reflect the condition of the fabric more objectively, the test data of each region should be increased. Comparability, so it is necessary to explore a set of scientific testing methods. Let's talk about some superficial views based on the testing work of silk fabrics in recent years.

1. The effect of the warp and weft direction of the fabric on the test results

The produced ZBD Tester is a special device designed for testing the strength of paper, so it requires the sample to be tested to be a sample with a relatively smooth surface like paper and ceramics. Various factors such as the organizational structure of the textile, the thickness of the warp and weft, the hair, the degree of weaving, the density of the warp and weft, and the changes in the weaving process have formed various uneven states on the surface of the fabric. Such different concave-convex surface pairs 45 . The incident light projected from the direction produces different phenomena such as reflection, scattering, transmission and absorption inside the fiber fabric. Among them, the reflection and scattering are largely related to the warp and weft of the fabric and the relative position of the incident light.

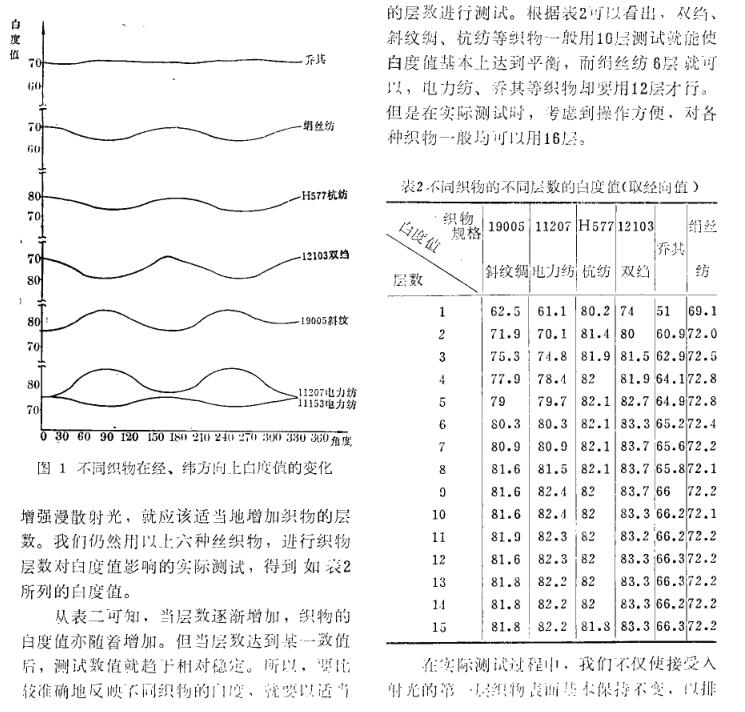

The curve shown in Figure 1 shows the change of the whiteness value of six different silk fabrics when the relative positions of warp, weft and incident light are different. In the actual test, we align the direction of the light bulb with the warp of the fabric, that is, the weft of the fabric is parallel to the instrument and the plate is used as the zero point of the test, and this value is called the radial test value. Then every 30. Test a value. When turning 90. At this time, the weft direction of the fabric is just aligned with the direction of the light bulb, and the whiteness value measured at this time is called the weft direction test value. We measured 21 values for one revolution of the fabric. From Figure 1, we can clearly see that as the relative position changes, the test value also changes, and the change is 180" periodic. The maximum value and the minimum value are separated by 09°, that is to say, the warp One of them is the maximum value, and the other must be the minimum value. At the same time, it can be seen from Figure 1 that for different fabrics, or even fabrics of different specifications in the same organization, the maximum value and the minimum value are in the warp and weft The upward distribution is also different. For example: the whiteness value of 12103 Shuangluo, H57 Liaohang spinning and 11153 electric spinning is large measured in the warp direction and small in the weft direction, but 19005 twill silk and H270 electric power The whiteness value of spinning is large measured in the weft direction and small measured in the warp direction.

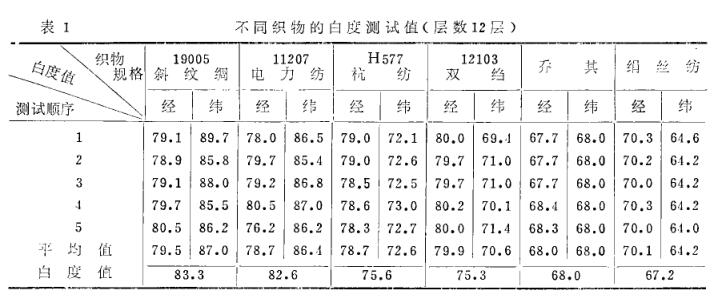

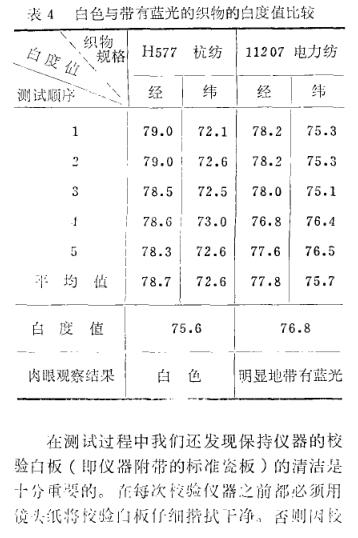

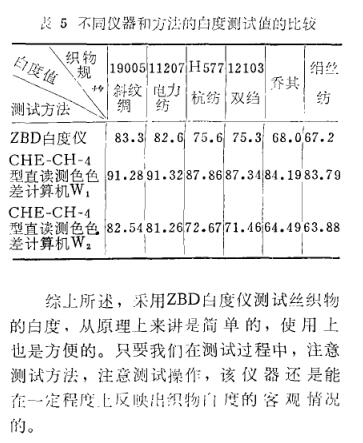

-According to the above test situation, if we only take the warp or weft self-degree test value of the fabric as the whiteness of the fabric, the edge array cannot reflect the warp and weft differences between different fabrics, or even between fabrics of the same organization and different specifications. Different distribution of maxima and minima. Moreover, it is possible to observe the fabric from the warp direction and weft direction in actual taking. So we still use the customary method of textile testing: that is, select the whiteness points of more than 5 test points in the warp direction and weft direction respectively, and then take the average as the whiteness value of the fabric. Table 1 shows the average whiteness values of the six fabrics in Figure 1 obtained by the above method.

2. The influence of different layers of fabric on the test results

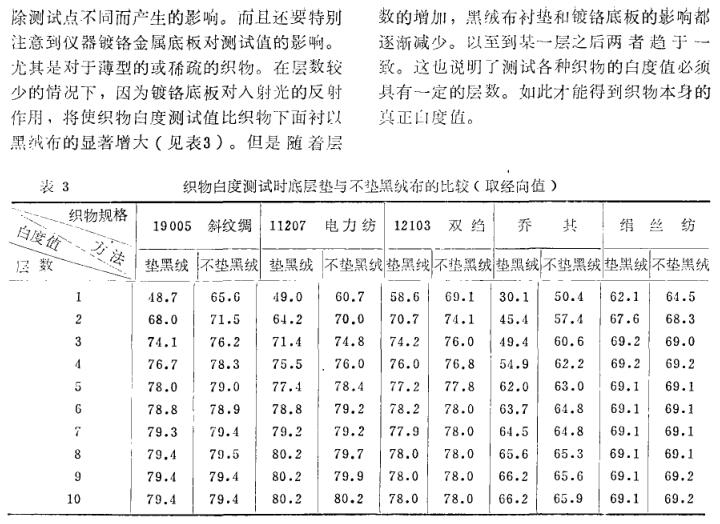

Due to the thickness of the fabric and the density of the warp and weft, the incident light projected on the surface of the fabric is partially transmitted through the fabric and damaged. !So, in order to reduce the loss of transmitted light,