After the pressure-sensitive adhesive is in contact with the adherend, as long as a certain pressure is applied, the surface to be adhered will be wet and the adherend will be firmly bonded to produce practical bonding strength. The pressure-sensitive adhesive performance of pressure-sensitive adhesives is its most basic performance, which is a distinctive sign that distinguishes it from other adhesives.

The test of pressure-sensitive adhesive includes two aspects, one aspect is the determination of the physical and chemical properties of the pressure-sensitive adhesive itself, such as appearance, solid content, viscosity, etc. The stability of the process and the stability and reliability of the bonding strength are very important. Determination of these indicators will be discussed in Section 10.2.

Another aspect of pressure-sensitive adhesive testing is the determination of the adhesive properties of pressure-sensitive adhesives, that is, the determination of various mechanical properties of pressure-sensitive adhesive products.

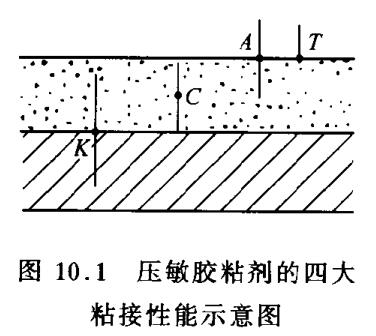

There are four types of adhesive force to characterize the adhesive performance of pressure-sensitive adhesives. This is the initial tack T (tack), adhesive force A (adhesion), cohesion C (co-hesion) and sticky force K (keying), see Figure l0.1. A pressure-sensitive adhesive with good performance needs to satisfy the following balance relationship:

T<A<C<K

Initial tack T, also known as fast tack, refers to the anti-separation ability shown when the pressure-sensitive adhesive product and the adherend are separated quickly after contacting with a very light pressure. Generally, it is the so-called hand-feel stickiness displayed when the finger touches the adhesive surface lightly. The definition of initial tack is actually quite loose. There are many methods for measuring initial tack according to the situation, and there is no comparability between the data measured by different methods. The determination method of initial tack will be in Section 10.4

Adhesive force A refers to the ability to resist interfacial separation between the pressure-sensitive adhesive product and the adhered surface after pasting with appropriate pressure and time. Generally, it is measured by the 180°peel strength of the adhesive product, which will be detailed in Section 10.3.

Adhesive force K refers to the adhesive force between the adhesive and the substrate, or between the adhesive and the primer and the primer and the substrate. When the 180°peel test occurs, the peel strength measured when the adhesive layer and the substrate are separated is the adhesion force. Under normal circumstances, the sticky base force is greater than the adhesive force, so this value cannot be measured.

Cohesion refers to the strength of the adhesive layer itself, which is generally expressed by the ability of the adhesive product to resist shear creep after pasting, that is, the holding force, which will be detailed in Section 10.5.

If the relationship between these kinds of adhesive properties satisfies the formula (l0.1), the adhesive product will not only have pressure-sensitive adhesive properties, but also meet the basic requirements of the application. Otherwise, various quality problems will arise. For example, if T ≥ A, there is no pressure-sensitive performance; if A ≥ C, the adhesive layer will be damaged when the adhesive product is removed, causing the adhesive to stain the surface to be adhered, drawing or sticking to the back; if c » K, there will be degumming (adhesive layer detached from the substrate) phenomenon.

It can be seen that the above-mentioned four major adhesive properties of pressure-sensitive adhesives and their relationship with each other are their basic properties. When researching and preparing pressure-sensitive adhesives and their adhesive products, it is first necessary to meet these performance requirements. Of course, other performance requirements, such as mechanical strength, electrical insulation performance, flexibility of adhesive products (the above are mainly determined by the substrate), and heat resistance, corrosion resistance, medium and atmospheric aging resistance (the above are mainly determined by the adhesive), etc., It also needs to be considered when selecting the substrate and adhesive formulation.

This chapter does not intend to do too much theoretical analysis on these characteristics, but focuses on the testing of these performances. For relevant theoretical analysis, please refer to relevant books.