提出了乳胶漆调色过程中常出现的问题,分析了产生这些问题的原因和解决方法;选用有配色软件支持的高品质色浆进行调色,是有效的方法。

1前言

采用水性色浆对乳胶漆进行调色,己被大多数涂料生产厂家所接受。在调色过程中需要对颜色、耐候性、遮盖力、涂膜的物理机械性能、调色价格、毒性等方面加以考虑,要做到各方面的优化是一件很困难的事,常会因为顾此失彼而出现各类质量问题。本文指出乳胶漆在调色过程中容易出现的问题,并分析其原因和解决方法,总结归纳出乳胶漆调色用色浆的很好的方法。

2问题分析及解决方法

2.1乳胶漆与水性色浆的相容性

用水性色浆对乳胶漆进行调色,首先必然要求水性色浆和乳胶漆有很好的相容性,若相容性不佳,则会产生絮凝、浮色、发花、着色力下降、色相偏移、细度増大、光泽降低、涂料稳定性变差等现象。判断相容性很好的方法是做指研实验,其操作方法为:将最大量的色浆加入到乳胶漆中,混合搅拌均匀后涂布在刮涂纸上,在其表干前用手指擦拭约一分钟左右,实干后观察擦拭部位与未擦拭部位是否有色差,若无色差,说明相容性好:若存在色差,则说明颜料存在絮凝,擦拭部位因受到外力的作用而解絮凝。也可用其它方法测试相容性:(1)观察色相变化絮凝会使色相红移;(2)测量细度;(3)淋涂实验。

产生相容性不良的原因一般有二种可能:一是色浆的分散稳定性差,易产生絮凝、浮色、发花等弊病,这要求用户应选用分散性、稳定性好的高性能色浆;另一个原因可能是乳胶漆内润湿分散剂的用量不足或不适宜,在色浆加入后乳胶漆内的颜、填料粒子抢夺色浆颜料表面的分散剂,使色浆颜料产生絮凝,这时需要増加乳胶漆分散剂的用量或改变润湿分散剂,直至通过相容性实验。

值得一提的是在色浆同乳胶漆相容性良好时,色浆加入乳胶漆后一般只需用分散机搅拌均匀或混匀机混合均匀即可,不再需要砂磨或高速分散。在砂磨或高速分散条件下的高剪切力会使乳胶漆内的颜、填料进一步分散产生新的表面,新生表面需要吸附分散剂来稳定,这可能会引起色浆内颜料的絮凝。

2.2颜色的准确性和重现性

The purpose of latex paint toning is to give rich colors to the paint, which requires the color to have good accuracy and reproducibility. Accuracy and reproducibility are both relatively independent and interrelated, and they are important to the user, and reproducibility between batches may be even more important to the same user.

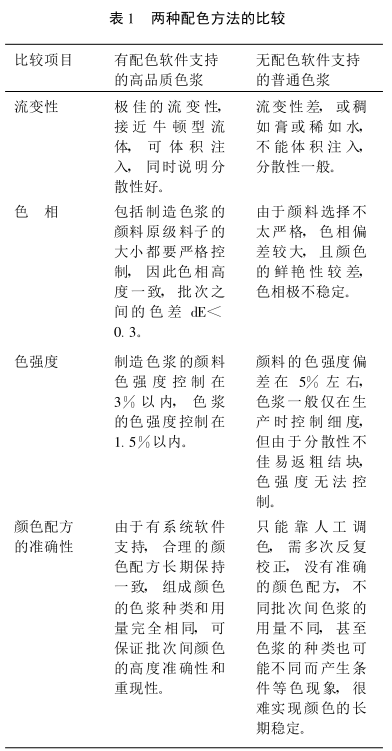

There are many factors that affect the accuracy and reproducibility of color, the most important of which are the stability of color paste quality, the accuracy of color formula and the stability of base paint. Under the premise of stable basic inspection, latex paint is toned by ordinary color paste without color matching software support. It is completely based on experience and needs to be corrected many times. With the high-quality color paste supported by the software, the color matching will have good accuracy and reproducibility. This is because they are essentially different in terms of the stability of the quality of the color paste and the accuracy of the color formula.

From the above analysis, we can realize that the simple and feasible way to achieve color accuracy and reproducibility is to use high-quality color paste color matching supported by color matching software.

2.3 Brightness of color

In the process of toning latex paint, it is often encountered that the color is not bright enough, or the saturation is poor. This situation may generally have the following reasons: (1) The saturation of the color paste is not enough; (2) The color paste system used cannot cover the entire color space well, and the color paste is far away from the color coordinate point to adjust the color , even if you can adjust very similar colors, the saturation will definitely be greatly reduced; (3) too much color paste is used in the color formula, and even complementary colors are used in the same formula, so that the saturation is also greatly reduced. Because the color mixing is subtractive mixing, the color will be dull; (4) the latex paint contains too much white pigment or the dry hiding power produced by too high PVC is diluted.

To obtain bright colors, the following issues must be paid attention to:

(1)制造色浆的颜料必需鲜艳,由于颜料的结构、晶型、原级颜料粒子的尺寸等方面都对颜色的鲜艳性产生影响,因此对制造色浆的颜料要严格控制;(2)采用的色浆系统要能很好地覆盖整个颜色空间,任何一种颜色都能从色浆体系内找到色空间距离较近的色浆来调制,这样可进而保证在不太大牺牲饱和度的情况下达到色相的一致;(3)颜色配方中选用的色浆种类应尽可能少,只要采用的色浆系统适当,任何一种颜色最多只要四种色浆均可调出,色浆的种类过多不仅颜色暗淡,而且不经济;(4)高饱和度的颜色一般不用白色颜料,而用清漆调制即可。若基漆内含有白色颜料或白色颜料过多,饱和度必定会降低或需要加入大量的色浆来达到足够的饱和度,这样将使调色成本大大提高,同时还可能影响涂料的其它性能;(5)乳胶漆中常采用通过提高涂料的PVC产生“干遮盖力”的办法来降低成本当调制高饱和度的颜色时,这种“干遮盖力”会象白色颜料一样,冲淡色彩,降低饱和度,因此涂料的PVC不可太高,一般不应大于45%。

而配色软件支持的高品质色浆系统能完全覆盖整个色空间,每种色浆色相和色强度都有严格控制,有很好的鲜艳性,在全部颜色配方中遵循同一配方不使用互补色,According to每个配方最多使用四种色浆的配色原则,可充分保证颜色的鲜艳性。

2.4耐候性

耐候性是外墙乳胶漆重要的性能之一,但由于检测时间长、测试仪器昂贵,到目前为止还没有很好的检测方法,因此它是涂料生产厂家最难把握、最易出现质量问题的指标。弓丨起耐候性差的原因常有以下几种:(1)颜料的化学结构和晶型不适宜;(2)浅色漆和深色漆中选用了耐候性相同的色浆;(3)颜料的粒径太小;(4)漆内乳液的耐候性太差;(5)涂料的颜料体积浓度过大等因素。因此要获得耐候性较好的涂料,需要综合全面地考虑以上各种因素。

颜料的耐候性能主要取决于它的化学结构及晶型。无机颜料中的金红石型钛白、氧化铁系颜料有极好的耐候性,是外墙乳胶漆中应用最多的颜料。锐钛型钛白、立德粉、铬酸铅类颜料由于耐候性差,不能在外墙涂料中使用。钒酸铋类颜料有很好的耐光性,但由于遮盖力差、价格昂贵,在外墙涂料中也很少使用。耐候性优良的有机颜料在化学结构上有分子量大、分子内含卤素原子、极性基团、金属原子和分子间可形成氢键等特点。有机颜料中用量最大的为酞菁系列颜料,酞菁兰(PB15:4、PB15:3、PB15:1)、酞菁绿(PG7、PG36)均有很好的耐候性,可用于不同色域的外墙乳胶漆中。

外墙涂料中最难选择的是红色和黄色,需要综合考虑颜料本身的耐候性、颜色的深浅以及着色力和价格等方面。

在外墙涂料中常用的红色颜料有单偶氮红(PR112)、喹吖啶酮红(PR122)、喹吖啶酮紫(PV19红相紫)、蒽醌酮红(PR168)等颜料。单偶氮红颜料耐候性一般,但着色力高,颜色鲜艳;喹吖啶酮颜料无论是深色还是冲淡色的耐候性均好,冲淡色的耐候性甚至还略有提高;蒽醌酮红的耐候性很好的。由于有机颜料冲淡色和深色相比耐候性下降,因此PR112不能用于浅色,可有限度地用于中间色域主要用于深色大红,浅色则用耐候性更好的喹吖啶酮颜料和蒽醌酮红颜料来调色。希必思公司的monicoloI•调色系统对此则有严格的规定:PR112不能用于A基漆(白漆)中,在B基漆(半白漆)中用量每升不得少于136个单位(一个单位=0.308ml)在C基漆(清漆)中用量不得少于钛白浆用量的一半。此规则可保证每个颜色配方都有很好的耐候性。DPP系列红颜料(如PR254)有很好的耐候性,但其价格太高,性能己超过乳胶漆对颜料的要求,很少用于乳胶漆中,而主要应用于高档汽车面漆中。

外墙涂料中常用的黄色颜料有单偶氮黄(PY74)、双偶氮黄(PY83)、喹啉黄(PY138)和异吲哚啉酮(PY109)等颜料。偶氮颜料为传统的有机颜料,耐候性一般,但颜色鲜艳,着色力好,且价格便宜,主要用于中、深色的着色;喹啉黄和异吲哚啉酮的分子内都含有极性基团,分子间可形成强烈的氢键,使它们有极好的耐候性能,其冲淡色的耐候性也可达到4~5级,主要用于浅、中色色域的着色。如何正确地使用普通黄色有机颜料和高性能黄色有机颜料,在monicoloi•调色系统中有极严格的

配比规定,保证调色配方有很好的耐候性。

获得外墙涂料高耐候性的另一种方法是在颜色设计时尽可能选用中、低彩度的颜色,便可采用无机颜料或无机颜料和有机颜料一起来调色,这一点无论是从颜色美学还是从经济性上考虑也都是一致的,从各大涂料公司的外墙色卡也能得出这一结论。

色浆内颜料粒子的直径变小,着色力提高,但耐光光泽度会变差,因此颜料的粒径不是越细越好,而应控制在某一适当的范围之内。高品质色浆的细度都严格控制在适当的范围内,在加入到乳胶漆中后只需搅拌均匀或用混匀机混合均匀即可,不用再继续砂磨,否则不仅会出现上述分散剂的重新分配引起的颜料絮凝,还会出现因颜料细度过小而导致的耐候性降低。

乳胶漆的耐候性能在很大程度上取决于乳液的类型、涂料的PVC等因素。乳液的耐候性差,易被破坏,颜料则失去了保护,受到的辐射密度加强,耐候性变差;涂料的PVC越高,一方面颜料粒子受到基料的保护越少,耐候性变差;另一方面涂膜表面越粗糙,吸收的光和热越多,也加快了颜料的破坏速度,耐候性变差。因此要得到保色耐候性好的涂料,不仅要求颜料的耐候性要好,还要求选用耐候性优良的纯丙、硅丙、苯丙等乳液,且涂料的PVC不可太高。

2.5遮盖力不足或遮盖力过剩

色浆不仅赋予乳胶漆丰富的色彩,还有一个重要功能是提供乳胶漆的遮盖力,这一点往往易被大家忽视,因此也是常出现质量问题之处。

由于现行的乳胶漆国家标准中仅对白色或浅色有对比率的要求,对中间色及深色无遮盖力的具体指标,因此许多厂家对中间色和深色的遮盖力没有控制。中间色和深色含钛白较少,含有机颜料较多,而有机颜料的遮盖力较差,因此中间色和深色最易出现遮盖力不足的问题,有些厂家甚至向其用户提出浅色涂二道,中间色涂三道,深色涂四道的要求,显然这种要求很难让用户接受。解决问题的方法有:(1)基础漆的钛白含量要适宜,要分别用钛白含量为高、中、低不同的基础漆来进行浅、中、深色的调色,钛白能提供给涂料很好的遮盖力,但用量过少,涂料很难有较好的遮盖力;(2)通常无机颜料的遮盖力比有机颜料的遮盖力要好得多,因此在设计颜色配方时要尽可能使用无机颜料或无机颜料和有机颜料一起来调色;(3)在选用有机颜料时,不但要求颜料具有较好的耐候性和着色力,还要求其具有较好的遮盖力。

另一种常见问题是遮盖力过剩。国内许多中小型涂料厂习惯生产白色乳胶漆,很少甚至根本不生产半白乳胶漆和乳胶清漆,常用半白漆来调深色,用白色漆来调中间色甚至深色,这样必需加入大量的色浆才能达到一定的饱和度,其结果是:(1)白漆己有很好的遮盖力,加入大量色浆后遮盖力产生严重过剩;(2)大量色浆的加入将会使调色成本成倍提高;(3)色浆超过最大加入量时将使涂料的耐水性、耐擦洗性等性能产生严重影响。

现代调色系统According to颜色的深浅不同,通常选用三种钛白含量不同的基础漆来调色,精选很好的遮盖力的颜料,同时充分考虑尽可能选用无机颜料的原则设计每个颜色配方,可避免发生遮盖不足或过剩的问题。另外,乳胶漆的遮盖力还要According to涂膜的厚度来设计,颜色配方一般是按干膜厚度为30^m~60um的涂料设计的,当干膜厚度大于60^m(如弹性涂料)时,应对调色配方进行调整,适当降低涂料的遮盖力。采用调色系统的用户可以很方便地通过调整颜色管理软件中的色浆分配注入规则来实现全部颜色的调整。

2.6色漆涂膜的性能

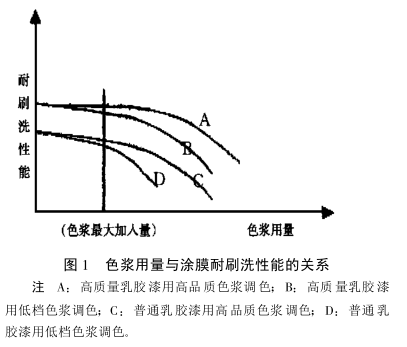

The use of high-performance colorants for coloring does not exceed the maximum amount, and it has almost no effect on the performance of the paint, but when using low-grade colorants or improper use of colorants, it may have a great negative impact on the performance of the paint, making the paint Water resistance, scrub resistance, alkali resistance, gloss and other properties are reduced, so that the original qualified base paint becomes an unqualified product. This effect is especially serious for medium and low-grade latex paints. Figure 1 shows the effect of the addition of different quality colorants on the scrub resistance of different quality latex paints.

Low-grade colorants use ethylene glycol as a humectant in large quantities, which are highly hydrophilic, and low-cost emulsifiers and wetting agents to disperse and stabilize pigments; high-grade colorants use propylene glycol as a humectant, and a large number of high-quality dispersants are used to disperse and stabilize pigments. pigment. Ethylene glycol has stronger water absorption than propylene glycol, and its volatilization rate is slower during the drying and film-forming process of the paint. Especially under low temperature and high humidity conditions, its volatilization rate may be lower than that of the film-forming aids, which affects the fusion of the emulsion and film formation. Emulsifiers and wetting agents have a certain degree of hydrophilicity, and because the dispersion effect is not as good as high-quality dispersants, they are used in large amounts and will remain in the coating film for a long time, affecting the water resistance, scrub resistance, and alkali resistance of the coating film.

Another reason for the poor performance of the paint film is the improper selection of the base paint. As mentioned above, when white base paint is used to adjust the middle color or semi-white paint is used to adjust the dark color paint, the amount of color paste will increase exponentially. If the maximum amount of color paste is exceeded, the paint will be seriously affected. Film formation, and the content of hydrophilic substances in the final coating film will be greatly increased, and the water resistance and scrub resistance of the coating film will be significantly reduced. For color matching supported by color matching software, white paint, semi-white paint and varnish with different titanium dioxide content are selected for color matching according to the depth of the color. The amount of color paste cannot exceed the maximum amount, so it has almost no effect on the performance of the base paint .