With the help of Colibri color matching software and Spectrophotometer and other instruments, a database of wood floor paint color precision was established, and a preliminary test of computer color matching of solid wood floor paint was carried out. The results show that the established color precision database can meet the needs of color matching, and the deviation value of computer color matching for red oak floor paint is 3.37~6.73; the uneven color of wood itself has a greater impact on the accuracy of color measurement and computer color matching of paint.

With the continuous development of science and technology, computer color matching technology can basically realize the accurate measurement and evaluation of color, and has been widely used in the fields of textile industry, garment processing industry, printing industry, dye manufacturing industry, paint industry, paper industry and photography. application. Computer color matching technology has a quantitative analysis of color, less interference from the outside world, fast color matching, high accuracy, and the calculation formula can be archived for information management. The application of computer color matching technology can improve the production efficiency of enterprises, reduce production costs, and has certain actual economic benefits.

In the wood industry, computer color matching technology has not been well applied, and the research on the application of computer color matching technology to wood still stays in the aspect of dyeing. Wood has beautiful texture and unevenly distributed color, and there are certain differences in the color of wood between different tree species. The color of wood of the same tree species is also different due to the influence of factors such as heart, sapwood, early and late wood, and wood defects. In actual production and application, in order to make wood products show the natural texture of the wood itself, varnish is generally used for wood paint. Sometimes it is more difficult to change the color of the wood itself.

1 Theoretical basis and application research of computer color matching

At present, wood paint color matching mainly relies on artificial color matching, and the difference in appearance between the finished product and the model is judged by the naked eye. Paint craftsmen add coloring agents entirely by experience, and adopt the "kneading" color matching method of "adding more water to the surface, and adding more water to the surface". This color matching method is not only time-consuming, but also a waste of paint. Therefore, the research of computer color matching technology applied to wood paint has great practical value. Theoretical Basis and Application of Computer Color Matching

At present, most color matching software in the world use Kubel-ka-Munk theory as the basis of optical theory. The theory is derived from translucent medium as an example, and it is a chaotic medium theory applicable to translucent and opaque mediums. It reflects the relationship between the light absorption and scattering ability of colored substances and the reflectivity of light, and provides a theoretical basis for the instrumental measurement of color. The simplified form of the theory is:

Color essence needs to be added to the paint for toning. Due to the difference and inhomogeneity in the color of wood, many researchers have proposed many new algorithms based on Kubelka-Munk theory, such as recursive quadratic approximation and optimization algorithm, Sander Mori correction and other more accurate algorithm models M. Zhao Chenfei proposed the use of color spectrum analysis for computer color matching, and Luo Guanglin et al.10 established a set of color matching algorithms for plastic gravure spot color inks based on the double-constant Kubelka-Munk theory, which further revised and improved the computer color matching theory.

2 Preliminary test of computer color matching of wood paint

2.1 Main instruments and materials

Test equipment: CM-2300d Spectrophotometer , Colibri color matching software, OSP-100 coating stick (coating film thickness is 100pm), KHC20 RK embossing bed, LENETA2DX black and white cardboard, electronic balance, plastic cup , glass rods, plastic droppers, beakers, etc.

Paint "Dulux Yamujia" brand wood varnish primer, including main paint, curing agent and thinner, and "Nippon" brand red, yellow and black oil color essences for color selection.

Test materials: red oak, black walnut solid wood composite floor board and painted sample floor, provided by Guangzhou Houbang Wood Industry Manufacturing Co., Ltd.

2.2 Test steps and process

There are 3 main factors in computer color matching: color database, base color and target color. The color database is the data source for computer color matching; the base color refers to the initial color of the object; the target color refers to the final color to be achieved after color matching. Computer color matching is based on the color difference between the base color and the target color, and with the help of the color precision database, calculates the addition ratio of each component of the paint, and finally generates a formula.

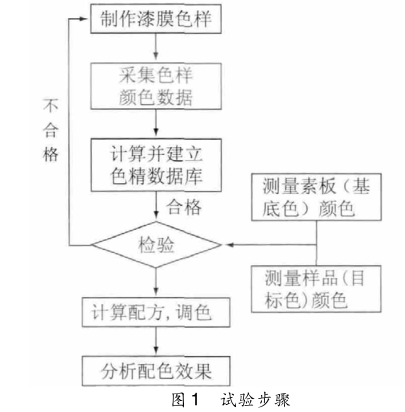

Figure 1 shows the test steps and process. First, make paint film color samples of different color essence paint materials, collect color data of the color samples, and initially establish a color essence database; then pass a color matching test to observe and analyze the color difference between the color sample and the standard sample, and check the accuracy of the database, such as color matching If the effect is unqualified, the color precision database needs to be re-established. If the color matching effect is qualified, the color precision database has been established; then use the established color precision database to carry out the color matching test of red oak solid wood flooring. Measure the color of the plain floor board as the base color, measure the color of the red oak painted sample floor as the target color, calculate the formula for color matching, and analyze the color matching results.

2.3 Establishment of color precision database

The color precision database is the core component of the computer color matching system and the calculation basis of computer color matching. The accuracy of color precision database directly affects the accuracy of color matching results. The establishment of color essence database is the process of establishing a mathematical model of the specific color characteristics of paint and color essence. With the help of Colibri color matching software, the color of different samples and the addition amount of each component are collected for calculation, and a relevant database is established.

2.3.1 Production of paint film cardboard color samples

The primer purchased has 3 groups of raw materials: main paint, curing agent and thinner, and the mass ratio of each component in the primer prepared during the test is 2:1:1.

During the preparation process of each group of paints, clean plastic cups were selected as paint mixing containers. Weigh the main paint and curing agent first, stir them evenly with a glass rod, then add diluent and stir further, and finally add color essence for toning.

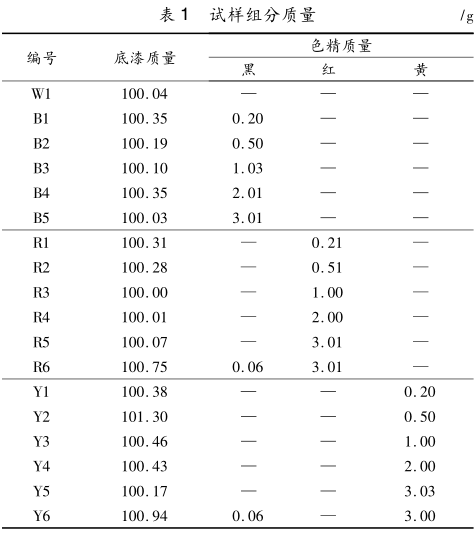

Due to the limitation of laboratory conditions, the weighing of various color essence components cannot be absolutely consistent. The mass of each color essence component in Table 1 is the actual weighed mass, and the weighing of each group of primers also has certain differences, which does not affect the establishment of the color essence database. The more samples there are, the more accurate the established mathematical model will be, the more accurate the database will be, and the better the color matching effect will be. By detecting the color of samples made with different concentration of color concentrates and collecting a large amount of color data, the color characteristics of paints and color concentrates can be effectively grasped, and a good color concentrate database can be established to meet the needs of color matching.

In Table 1, W represents primer, B represents black color essence, R represents red color essence, and Y represents yellow color essence. The amount of color essence added in each group is reasonably set according to the dosage range of color essence. The amount of color essence used in this test ranges from 0 to 3%, and the paint material is 100g, so the amount of color essence added does not exceed 3g. Due to the small range of the amount of color essence used, 5 kinds of additions (0.20%, 0.50%, 1.00%, 2.00% and 3.00%) were selected for the test, and a total of 18 groups of paint samples were produced. W1 group did not add any color essence, mainly reflecting the color characteristics of the primer; B1~B5 group only added black color essence, R1~R5 group only added red color essence, Y1~Y5 group only added yellow color essence, to explore the individual color essence The color characteristics of the color essence; R6 group and Y6 group both added a small amount of black color essence to explore the color characteristics of black color essence mixed with red color essence and yellow color essence.

将各组油漆试样不断搅拌均匀,再将黑白卡纸进行编号,装夹在RK压印床上。吸取适当漆料滴至平放的黑白卡纸上,将涂膜棒置于黑白卡纸上,自上而下刮膜,刮膜时力度均匀,动作迅速、流畅、不停顿,漆膜厚度为100^m。待漆膜卡纸色样晾干后进行测量,每组漆料制作3张漆膜卡纸色样,取平均值。2.3.2色精数据采集与配色偏差计算

将各漆料组分质量及漆膜厚度输入Colibri配色软件,搭建色精数据库框架。之后将晾干的漆膜卡纸色样逐一采用分光测色计进行检测,得到L*a*b*色空间和L*C*h色空间的数字数据,以及各种颜色的光谱反射曲线。将测得的各漆膜卡纸色样的L*a*b*色空间的颜色指标(明度L*、红-绿坐标a*、黄-蓝坐标b*)和L*C*h色空间的颜色指标(明度L*、饱和度C*、色调^)的实际值导入Colibri配色软件,搭建完整的色精数据库。

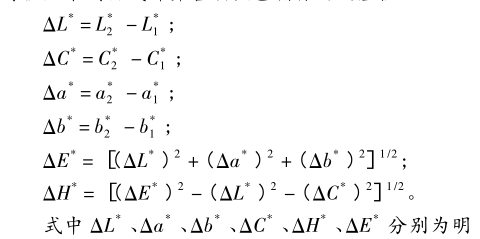

According to表1中的试样组分数据,可以由Colibri配色软件计算得到各组漆料的明度L2*、红-绿坐标a*、黄-蓝坐标b2*、饱和度C*及色调的模拟值,然后再按照下列公式计算各项颜色指标的偏差值:

明度差、红-绿差、黄-蓝差、饱和度差、色调差和配色偏差,均能判断色精数据库的准确度。在计算完成后色部分漆膜试样的AL*、AC*、AH*、AE*数值。各组漆膜卡纸色样的AL*、AC*、AH*、AE*值越小,所建立的色精数据库准确度越高。若AE*的值较大,则应将该色样的颜色数据舍去,重新计算数据库。AE*表示试样实际值与模拟值之间的色差,是判断颜色差异的最终标准。人眼所能观察到的色彩差异AE*值在1.0~1.5,对于AE*值的评判在各行业均有_定的共识,考虑到木材具有美丽的木纹,木地板油漆时_般选用清漆,木地板油漆调色有较高的难度,一般AE*<1就可认为配色效果较为称心。AE*的最大值也可以According to实际要求设定,AE*的最大值越大,要求越低,反之则要求越高。

2.3.3色精数据库分析检验

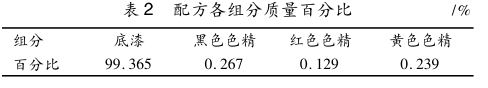

为了验证数据库的准确性和实用性,以黑白卡纸上的白色为基底色,在黑胡桃木地板素板上某一固定位置取样并作为标准样进行配色试验,以期获得地板素板本身颜色的配方。According to色精数据库,选择着色剂系列、基底色和标准色,通过计算得出配方,见表2。

按照配色系统计算出的配方调配漆料,实际称量底漆99.37g、黑色色精0.27g、红色色精0.13g、黄色色精0.24g。搅拌均匀后,取样涂抹在黑白卡纸上,用涂膜棒刮膜,漆膜厚度为100^m,待漆膜干燥后,对比配色效果。

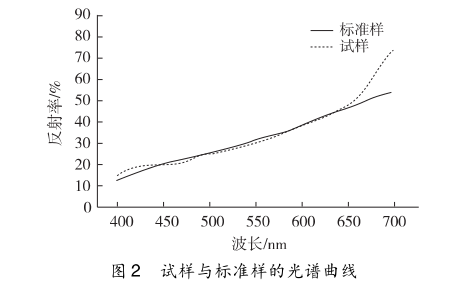

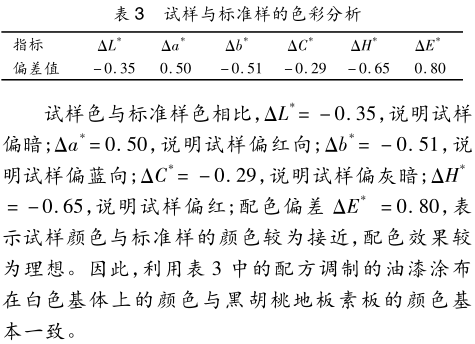

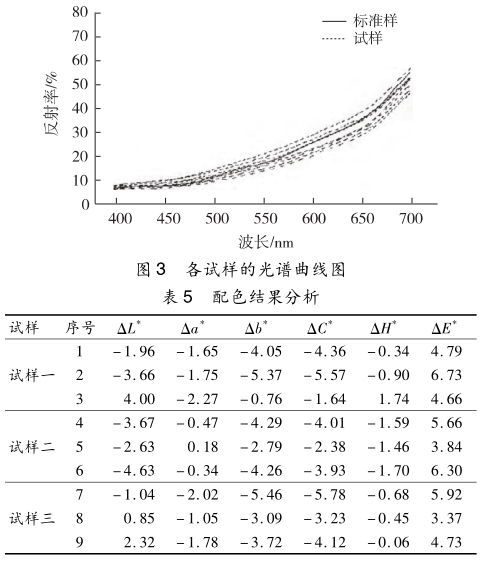

用分光测色计测得试样的颜色数据,录入计算机进行进一步对比。通过计算,得到试样的光谱曲线图与标准样的光谱曲线图(图2),并利用2.3.2中的公式对试样色与标准色的色彩数据计算分析(表3)。

图2中的纵轴为反射率,横轴为可见光的波长。可见光谱波长范围近似为400~700nm,波长700nm的光为红光,波长400nm的光为紫光,从波长700nm到400nm依次为红、橙、黄、绿、青、蓝、紫。如果光谱曲线相近,则人眼所看到的物体的颜色也就相似,反之则有一定的区别。从图2可以看出试样的光谱曲线与标准样的光谱曲线存在_定的差异,在曲线图的两端表现得尤为明显,说明试样对于紫光和红光的反射率大于标准样,配色效果存在_定的误差。

2.4红橡木实木地板计算机配色试验

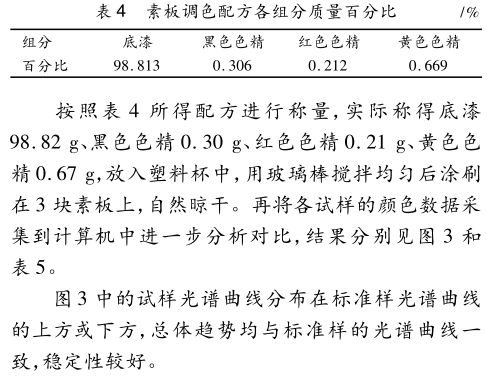

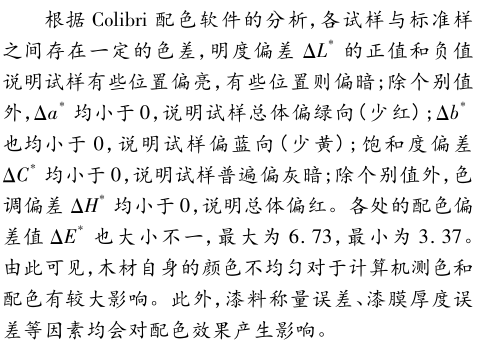

采用红橡木实木复合地板作进_步的油漆计算机配色试验,选取3块地板素板和1块油漆过的成品地板。使用分光测色计从成品地板上取色作为标准色,取素板试样的颜色作为基底色,基于色精数据库进行油漆配方计算,According to配方进行调漆,并涂刷到地板素板上。由于木地板本身的颜色不均匀,因此,测色时均采用多次测量取平均值的方法,提高取色的准确度。

试验所选3组试样虽然是相同树种,但能看出各试样之间的颜色存在_定的差异。从3块素板中取色作为基底色,取成品地板的颜色作为标准色,选择着色剂系列,计算所得配方见表4。

3结论

(1) In this experiment, according to the usage range of the color essence used, the color data of the color samples were collected, and the wood paint color essence database was established. The color precision database established according to this method can meet the needs of computer color matching for wood floor paint.

(2) In the red oak solid wood floor color matching test, there is a gap between the color matching effect and the standard sample, the color matching deviation AE* is greater than 1, and the color matching deviation value of each place is different. Due to the uneven color of the wood itself, it has a great influence on the accuracy of color measurement and computer color matching of paint. Therefore, such color matching deviation is acceptable in the production and use of wood flooring.

(3) In addition to color, wood paint also needs to be able to fully express the texture beauty of the wood itself. In the future, further research should be carried out in combination with the wood floor paint process of the factory and the experience of senior painters.