The appearance of clothing fabrics has a very obvious impact on the overall effect of clothing. The perception produced by it is the visual style of clothing fabrics. It is not only related to the printed graphics and colors of the cloth surface formed by printing and dyeing, but also related to the luster, cloth pattern and color of the fabric. Drapability. With the development of society and the advancement of technology, the design of clothing fabrics and the development of new products pay more attention to the principle of people-oriented and human sensory responses. The research on the style of clothing fabrics just meets this demand. Fabric luster is the main factor affecting the visual style of clothing fabrics, and this paper focuses on it.

1 Gloss and luster of clothing fabrics

1.1 Glossiness of clothing fabrics

When people look at something, according to their own experience, in addition to looking at its shape and color, they will also look at its reflection under light sources such as light bulbs and glass windows, and say that it is glossy or dull; Silk and rayon, it is said that the luster of silk is good. The feeling of this luster is a psychological reaction of human vision to the luster of the observed object.

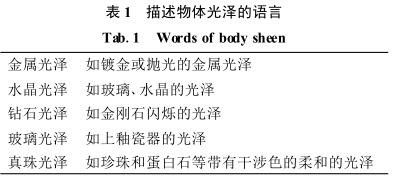

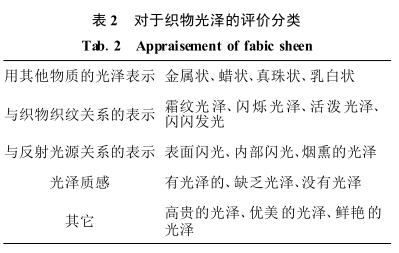

According to the strength of fabric luster, fabrics can be divided into strong luster fabrics and weak luster fabrics, which can also be called the amount of luster; fabrics can be distinguished according to the quality of fabric luster, which is called luster Quality. Strong glossy fabrics do not necessarily have a good glossy feel. The concept of glossy quality has a lot to do with psychological factors, which can be realized from the language describing the luster of clothing fabrics. See Table 1 and 2.

1.2 Gloss of clothing fabrics

Color depends on the wavelength of light, and image perception depends on the imaging of light on the retina. It is still unclear which properties of light determine the gloss. However, the analysis of existing research and language describing gloss shows that the gloss of objects is related to The reflected light of the object is closely related. There are two aspects of optical properties related to gloss.

1.2.1 Surface reflected light The surface reflected light is divided into regular reflected light and diffused light, and the surface state of the fabric is quite different. Therefore, the proportion of these two parts of light in the entire surface reflected light is also quite different. The strength of the surface reflected light Weakness and distribution have always been the main object of fabric gloss research and testing.

1.2.2 Internally reflected light After the light refracts into the object, the part of the light that is reflected from the object and re-enters the original medium is called internally reflected light. The internally reflected light shows the color of the object due to the selective absorption of the material. From the perspective of distribution, internal reflection Light can also be divided into directional reflected light and diffused light. In addition, due to the dispersion phenomenon, the internal reflected light will form a colored halo, which is the chroma of the textile material. It is generally believed that the internal reflected light has a greater effect on the texture of the fabric luster. relation.

2 Gloss evaluation and testing of clothing fabrics

2.1 Evaluation mode of fabric gloss

The luster of clothing fabrics belongs to visual perception. When evaluating the luster of fabrics, we should not only consider its luster abstractly or in isolation, but first associate it with its use (type of clothing) based on the commodity attributes (type, raw material, etc.) of the fabric. In order to evaluate the luster of the fabric, and consider the overall style of the fabric. The evaluation is based on the past visual impression, and there are two types of evaluation criteria: one is to pursue natural textures such as silk, wool, etc.; the other is based on visual The law of aesthetics, the evaluation results are affected by personal characteristics, customs and fashion trends. It can be said that the evaluation of fabric luster is a complicated problem. At present, the commonly used methods are divided into two categories, namely sensory evaluation and instrument testing.

2.2 Sensory evaluation of fabric gloss

The fixed method is generally to gather an appropriate number of experienced inspectors to inspect the fabric under a certain environment, and the result should be a comprehensive reflection of the visual style of the fabric. Ranking is widely used when evaluating several fabrics to determine their relative advantages and disadvantages. Rank method, that is, the fabrics that need to be evaluated are evaluated by several inspectors separately, and the quality of the gloss is ranked according to their own judgments, and then the quality of these fabrics is evaluated according to the total number of ranks of various fabrics ; or an inspector repeatedly evaluates the gloss of several fabrics, ranks the pros and cons of each evaluation, and then calculates the total rank.

The sensory evaluation method of fabric luster has the advantages of simplicity and speed, and other methods cannot replace it at present, so it is commonly used in business inspection. The disadvantage of this method is that it has human factors, and it is related to the proficiency and psychological state of each inspector .In addition, subjective evaluation can only give a concept of the relative quality of the fabric gloss, not a quantitative value.

2.3 Instrumental determination of fabric gloss

2.3.1 Gloss Intensity There are many methods for measuring gloss intensity, the more suitable fabric is contrast gloss, that is to measure the ratio of reflected light intensity under two different conditions, the common methods are: two-dimensional and three-dimensional contrast gloss; FJeffries contrast gloss etc.

2 Gloss texture Texture is a kind of psychological perception. Research reports on this test include: Micro gloss meter method, which mainly considers the influence of texture on gloss; Polarized gloss meter method, based on the principle of distinguishing internal and external reflected light .

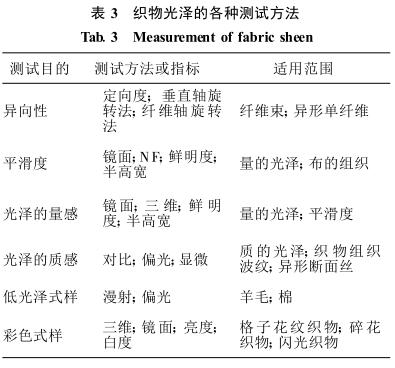

The physical test of fabric gloss is still in the process of research and exploration, and it is difficult to propose a systematic measurement method and index system for a while. The simple classification is shown in Table 3.

3. Factors related to fabric gloss

From the properties of the fiber itself to the overall sensory evaluation of the fiber into the clothing fabric, the evaluation of the fabric gloss is based on human visual perception. The sensory and processing processes will have different degrees of influence on the luster of the clothing fabric.

3.1 Properties of fibers

在影响服装面料光泽的诸多因素中,纤维的性状无疑是重要的一个因素,主要表现在3个方面.

3.1.1纤維的表面状态纤维的表面状态差异较大,有些纤维的表面很光滑,如天然纤维中的蚕丝,化纤长丝中的有光涤纶、锦纶等.而大部分纺织纤维的表面是不光滑的,如棉纤维表面的皱纹、沟槽和天然转曲;羊毛表面的鳞片和天然卷曲;多数湿法纺丝的化学纤维及半光或无光化学纤维的凹凸不平等.纤维的表面状态会影响到镜面反射光的强弱,纤维表面光滑,镜面反射光就强,其光泽感也就强,蚕丝及有光化纤长丝制作的锻子织物充分体现了这一特性.另外纤维的表面状态还会影响到折射和透射光的分布.

3.1.2纤維的截面形状纤维的截面形状多种多样,天然纤维中除羊毛纤维的截面为近似圆形外,多数纤维为非圆形截面;化学纤维的截面形状可以人为改变,多种多样.不同截面形状的纤维,其光泽效应差异较大,其中Y形和三角形截面的纤维光泽感较强,而且有“闪光”效果,因此,称这类纤维为“闪光纤维

3.1.3纤維截面的层状构造如果纤维的截面有层状构造,会在纤维内部各层形成多级内表面反射光,这些内表面反射光在纤维表面形成柔和、均匀、有层次、类似珍珠的光泽,会提高面料光泽的质感.

3.2纱线结构的影响

3.2.1炒线的捻度纱线加捻会使纱线中的纤维倾斜、弯曲,从而改变纤维的反射光分布,使得服装面料表面的漫反射光増多,使其光泽减弱.

3.2.2炒线表面的毛羽纱线在纺织过程中,会有许多纤维的端头露出纱体的表面,形成毛羽,这些毛羽的排列是无规律的,会使漫反射光増强,从而使服装面料的光泽减弱.

3.3织物结构的影响

服装所用的面料多为机织和针织面料.针织面料为线圈结构,纤维的弯曲使得漫射光増加,降低了面料的光泽所以,针织面料的光泽一般较弱.机织面料的组织结构不同,其光泽差异较大,主要影响因素有两方面.

3.3.1 The structural phase of the fabric The structural phase of the fabric determines the bending state of the warp yarn in the fabric and which system yarn is close to the surface of the fabric. The more curved the yarn, the stronger the diffuse light and the weaker the gloss. Under certain conditions, the reflected light distribution of the two systems of warp and warp yarns is quite different, so which system yarn is closer to the fabric surface has a significant impact on the fabric gloss.

3.3.2 Warp and weft coverage of fabric Due to different fabric structures, the coverage of warp and weft floating points on the fabric surface is quite different. When the light conditions are constant, the distribution of reflected light of the warp and weft yarns is completely different, so the warp and weft yarns The proportion of floating points covered on the front of the fabric has a great influence on the reflected light distribution of the fabric.

3.4 Fabric finishing

3.4.1 Ordinary finishing In order to improve the luster of the fabric, the usual finishing methods include singeing, shearing and shaping, etc. The main purpose is to reduce the hairiness on the surface of the fabric, make the surface of the fabric smooth and flat, and increase the specular reflection.

3.4.2 Special finishing

There are three finishing methods related to the optical properties of fabrics:

Metal luster finishing, this method is to spray metal on the surface of the fabric, or process it by coating. Generally, copper or aluminum is sprayed on the surface of the fabric to form a golden or silver luster.

Pearlescent finishing, this method is to finish the pearlescent powder on the surface of the fabric by coating to form a pearlescent luster.

Retro-reflective finishing, this method is to finish the surface of the fabric with glass beads and reflective materials by a special coating method. This fabric has a directional reflection function and can be used as a marking material. Due to the existence of glass beads, this fabric The luster is similar to that of a diamond.

In addition, from the perspective of color, both brightness and chroma have an impact on gloss. The darker the object, the less diffuse reflection and the stronger the gloss; and the chroma is directly proportional to the gloss.