The relationship between the glossiness of water-based ink and various influencing factors was determined through experiments. The experimental results show that: the dispersion stability of water-based ink helps to improve the gloss of the ink; the water content of the water-based ink is large, and the gloss is reduced; the defoamer can reduce the viscosity of the system and affect the dispersion effect, which is unfavorable to the gloss. Influence; there is a certain curve relationship between the thickener and the gloss; after adding the thinner, the gloss is improved; the gloss of the water-based ink is better when the pH value is 9.0~9.5.

The glossiness of water-based ink refers to the ability of the ink print to reflect light at a certain angle. The gloss of the ink print is mainly produced by the conjunctiva after the binder is dried. The quality of the gloss of the ink will have a greater impact on the appearance of the printed matter. If the gloss is good, the color will be bright, and if the gloss is poor, the color will be dull. At present, water-based inks generally have the problem of insufficient gloss, which seriously hinders the application of water-based inks in the field of packaging and printing.

There are many factors that affect the gloss of the ink film layer. The analysis from the aspect of water-based ink mainly includes: the composition of the ink itself (the nature of the binder, the particle size of the pigment and its dispersibility in the water-based ink), ink additives, pH value, etc., all of which have an impact on the gloss. greater impact.

1 Experimental equipment and experimental methods

1) Experimental equipment

The flexographic printing suitability Tester IGT-F1 is produced in the Netherlands; the gloss meter (measured at an angle of 20°) KGZ-1A is produced by Tianjin Keqi High-tech Company; the laser particle size analyzer is produced by Zhuhai Occident Technology Co., Ltd.

2) Experimental method

Taking a group of water-based inks (red ink, black ink, yellow ink) as an example, use a flexographic printing suitability Tester (150L/in) to make samples respectively. After the samples are dry, measure their corresponding gloss. The measured gloss The black ink is 4.28, the red ink is 3.60, and the yellow ink is 4.50. Then change different parameters, measure the relationship between ink gloss and various influencing factors through experiments, and finally draw a graph according to the experimental data in order to obtain an effective method for changing gloss in actual printing.

2 Experimental analysis

2.1 Fineness and gloss

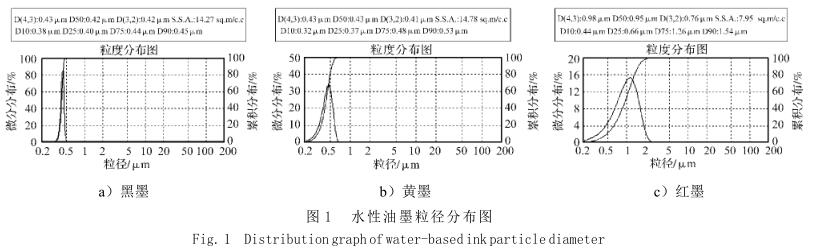

The water-based ink is tested by a laser particle size analyzer, and the particle size distribution of the pigment particles is shown in Figure 1.

It can be seen from Figure 1 that the particle size distribution (fineness) of water-based inks of different colors is different. The pigment particles of black ink are finer than red ink and yellow ink, but its gloss is not as good as that of yellow ink, which shows that The fineness of water-based ink has a very good value (as shown in Figure b), and only when the fineness of water-based ink reaches a good value, its glossiness is better. This is mainly because the good dispersion performance of water-based ink improves the fineness of the ink, and the fineness of the ink will directly affect the printing quality and leveling of the ink.

2.2 Moisture content and gloss

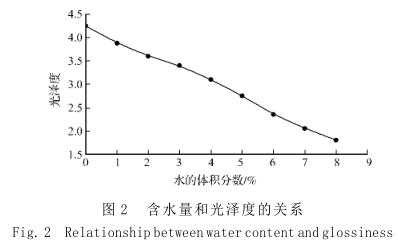

Divide the water-based ink (black ink) into several equal parts, and then add different volume fractions (1%~8%) of water to each part of the ink to dilute, and stir evenly with a glass rod, and make a sample. After the sample is dry, measure its corresponding of gloss. According to the data obtained from the experiment, the relationship between the glossiness and water content of the water-based ink is shown in Figure 2.

It can be seen from Figure 2 that the glossiness of water-based ink decreases with the increase of water content. Water-based ink uses water as a solvent, and the proportion of water has been set during the ink preparation process, so when the water content changes, it will affect the gloss of the ink. Therefore, in the actual operation process, the volume fraction of water in the water-based ink must be strictly controlled.

2.3 Additives and Gloss

2.3.1 Defoamer and Gloss

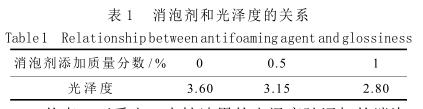

Divide the water-based ink (red ink) into several equal parts, and then add different mass fractions of defoamers to each part of the ink, and stir it evenly with a glass rod, and make a sample. After the sample is dry, measure its corresponding gloss. The result As shown in Table 1.

As can be seen from Table 1, the glossiness of the water-based ink decreases with the increase of the mass fraction of the defoamer added, which shows that when the defoamer is added to the water-based ink, the defoamer will have a negative impact on the dispersibility of the water-based ink. Adverse effects, resulting in poor ink gloss. This is mainly because the defoamer itself has low surface tension. Although it can reduce the amount of wetting and dispersing agent to eliminate foam, it will reduce the viscosity of the system, thus affecting the dispersion effect of water-based ink.

2.3.2 Thickeners and Gloss

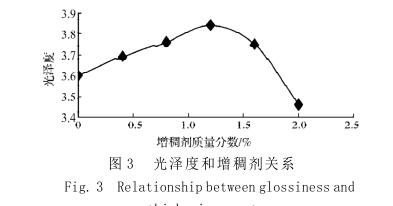

Divide the water-based ink (red ink) into several equal parts, and then add thickeners with different mass fractions (0.4%, 0.8%, 1.2%, 1.6%, 2.0%) to each ink, and stir evenly with a glass rod, and then Proofing, after drying, measured its corresponding gloss, the results are shown in Figure 3.

It can be seen from Figure 3 that the thickener can increase the glossiness of the water-based ink within a certain dosage range, but then with the increase of the mass fraction of the thickener, the glossiness of the water-based ink decreases instead. The addition of the thickener can improve the viscosity of the water-based ink. At the same time, the rheological properties such as thixotropy and suspension of the water-based ink are also improved, and the dispersion stability of the ink is improved, thereby increasing the gloss of the ink. However, with the further increase of the mass fraction of the thickener, the glossiness tends to decrease. This is because the viscosity increases correspondingly with the continuous addition of the thickener, which causes the ink absorption rate of the paper to decrease and the leveling property to deteriorate. Or it cannot be leveled at all, and the penetration, coagulation and conjunctival effects in leveling are significantly reduced, and the surface flatness of the obtained printed matter becomes worse, and the glossiness decreases.

In actual production, it is necessary to strictly control the amount of thickener added to ensure the high gloss of printed products.

2.3.3 Thinning agent and gloss

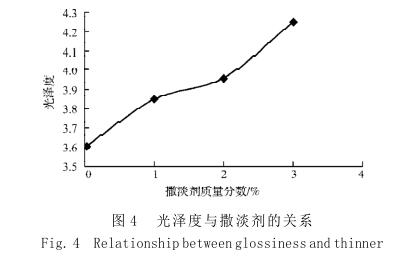

Divide the water-based ink (red ink) into several equal parts, and then add different mass fractions of lightening agents (1%, 2%, 3%) to each part of the ink and stir them evenly with a glass rod, and then place them on the IGT-F1 flexible Proofing was carried out on the plate printing suitability meter, and after drying, the corresponding gloss was measured sequentially, and the results are shown in Figure 4.

It can be seen from Figure 4 that after adding the lightening agent, the glossiness of the water-based ink has been improved. The thinning agent used in this experiment is a gloss paste type. Because of its good gloss, the prepared ink is light and transparent, and the ink film has a better effect, so it can enhance the gloss of the ink film.

2.4pH value and gloss

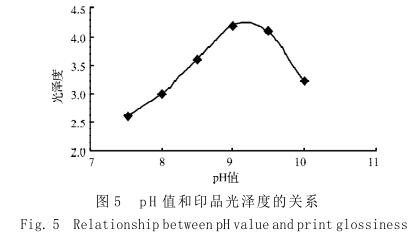

Change the pH value of the water-based ink (yellow ink), make proofs on the flexographic printing suitability Tester, and measure the corresponding gloss after drying. According to the data obtained from the experiment, it can be concluded that the relationship between the pH value of the water-based ink and the glossiness of the printed matter is shown in Figure 5.

It can be seen from Figure 5 that as the pH value of the water-based ink increases, the surface tension of the ink film decreases, and the water-based ink with a smaller surface tension can wet, adhere, and soak the surface of various substrates. Since the water-based ink is mostly dried through the mechanism of volatilization and penetration, the water-based ink can be leveled on the surface of the substrate to form a smooth and uniform film surface, so the glossiness is improved. However, when the pH value is too high, the leveling time of the water-based ink on the surface of the printed matter is too long, and the drying of the ink film will slow down, which will easily cause the back of the printed matter to be smeared, which will affect the quality of the printed matter. Therefore, in the case of ensuring a good gloss, the pH value of the water-based ink should be well controlled. It can be seen from the experiment that when the pH value is in the range of 9.0~9.5, the glossiness of the ink film reaches the highest value, and the printing quality can be guaranteed.

3 Conclusion

1) The additives in water-based inks have a certain relationship with the glossiness, and the amount of additives should be strictly controlled during production;

2) The pH value has a certain influence on the glossiness of the water-based ink. When the pH value is in the range of 9.0 to 9.5, the glossiness of the ink film is better;

3) Due to the limitation of experimental materials, only commonly used mid-range flexo printing water-based inks are used for experiments in this subject, which makes the gloss of the ink itself low. In actual production, in order to obtain higher gloss, it is also an effective way to choose high-grade water-based ink.