LVRI printing installed the InkZone closed-loop system compatible with the X-Rite IntelliTrax automatic scanning system on his KBAR apida 105 to make the ink closed-loop control. In addition, the ink preset data for each InkZone is transferred to the press by DI-Plot in the InkZone ink preset software. According to customers, the high quality of the data means that InkZone gives the printing press the highest level of safety and reliability when operating the system.

LVRI printing installed the InkZone closed-loop system compatible with the X-Rite IntelliTrax automatic scanning system on his KBAR apida 105 to make the ink closed-loop control. In addition, the ink preset data for each InkZone is transferred to the press by DI-Plot in the InkZone ink preset software. According to customers, the high quality of the data means that InkZone gives the printing press the highest level of safety and reliability when operating the system.

High technology behind the old facade

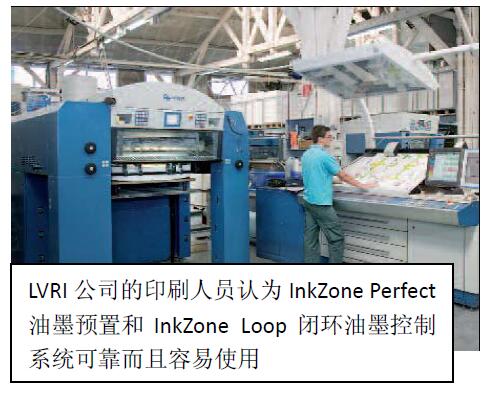

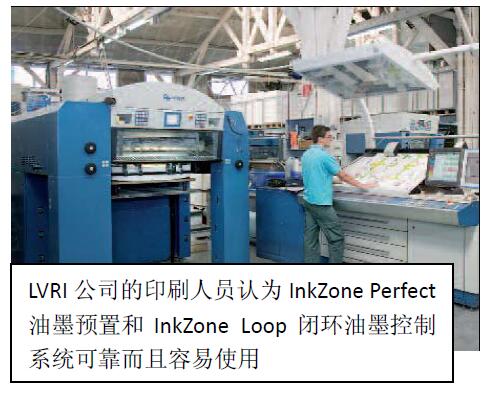

"We think the InkZone solution is the winner" With this brief sentence, FabriceHouillon expresses his enthusiasm for InkZonePerfect and InkZoneLoop. Together with his wife Mathilde, he runs the company LVRI, located in Corbel-Essone, south of Paris, with 20 employees. Despite being an old house, this printing company has maintained a high-tech focus. In the printing shop, there is a Rapida74 press with 4 printing units plus light unit, and a four-color Rapida105 press.

InkZone exceeds expectations

LVRI has been using X-Rite's ATD automatic scanning system for color control for the past 7 years. Since the adjustment of the ink keys cannot be directly transmitted from the ATD to the printing console, the preparation before printing is still a little slow, and the material waste is of course higher than that without ink preset. The system previously installed at LVRI was lacking in accuracy requirements, and the operating window was not satisfactory.

FabriceHouillon finally found the solution he was looking for in the form of the InkZonePerfect ink presets and the InkZoneLoop closed-loop ink control system. When asked about his enthusiasm for the product

When asked about the reason behind it, FabriceHouillon gave a succinct answer: "The InkZone solution of electronic information is completely reliable and very easy to use. As soon as the system is installed, we can apply the software to production." FabriceHouillon also confirmed that the system is very stable and does not require support so far.

Reliability brings high security

Reliability brings high security

InkZone's preset data is calculated by DI-Plot based on the bitmap generated by the RIP image processing device. It is sent directly to the press console via Ethernet. FabriceHouillon pays particular attention to the high-tech level.

“We can rely on the JDF files. These values create above-average accuracy of the required print job color files and we feel confident using them. With less squeegee/brush movement, the ink keys can

More are opened. When the ink keys are set with the correct calibration method, it can lead to better latitude"

the case

After replacing ATD with the new IntelliTrax scanning system, LVRI has a faster measurement speed. It only takes 15 seconds to scan a 105cm long print proof. InkZoneLoop displays measurement data for each printing unit on a graphical interface on the screen. Operators themselves can determine the range of adjustments suggested by the system that they can accept.

Commitment and quality remain the same

LVRI's headquarters was founded in 1954 by GeorgesHouillon. His brother and son Fabrice joined the company more than 20 years later and the company has been called LVR ever since. In the next 10 years, its printing technology developed rapidly, and in 1985, LVR changed its name to LVR International (LVRI). In the course of more than 50 years, LVRI has kept one thing consistent: high-quality achievements require a determined and professional team of employees.

Reliability brings high security

Reliability brings high security