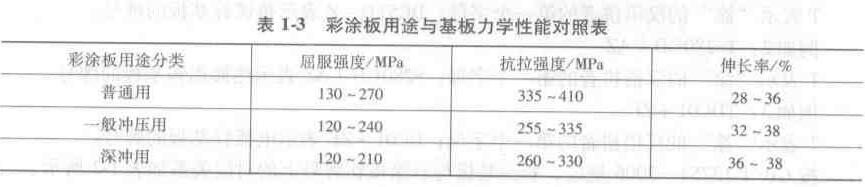

The performance of the forming and processing of the color-coated plate depends on the mechanical properties of the substrate and the properties of the coating. The properties of the coating such as thickness, gloss, solvent resistance, hardness, directional impact, etc. have already been set in the color coating process. Very strict detection and control methods, therefore, the mechanical properties of color-coated plates actually refer to the mechanical properties of the substrate. According to the steel plate grades stipulated in my country, there are many kinds of substrate grades that can be used for color coating, and they all have their own differences. Mechanical properties, therefore. When selecting, it should be selected according to factors such as the use, processing method and degree of deformation of the color-coated plate. According to the suggestion of GB/T 12754-2006, the color-coated panels used for building roofs usually use DC51D series grade substrates. For components with load-bearing requirements, appropriate structures such as S350GD and S550GD should be selected according to strength requirements Series of grades as substrates. For the processing of color-coated plates with large deformations such as shear rate, bending, rolling, etc., the substrates should be made of materials with better formability, such as DC520D and DC530D series substrates.