Since my country built the first color-coated sheet production line in 1987, the production technology of color-coated sheets has made great progress, and the production capacity has been greatly improved. Especially in the past two years, it has developed rapidly. More than 140 production lines have been built and rebuilt nationwide. The production capacity is about 7 million tons, which is more than 10 times the production capacity in 2000. At present, the quality grades of domestic color-coated products are uneven. On the one hand, the reason is that some small and medium-sized enterprises use substrates whose quality does not meet the coating requirements, reduce coating thickness, use low-grade coatings, and even use white, Blue paint acts as a primer to keep costs down. On the other hand, some users do not have a comprehensive understanding of the performance of color-coated panels, ignore the requirements for product quality, do not pay attention to the service life of the product, and only pay attention to the price, but do not fully achieve good prices. Therefore, it is very important to standardize and control the quality of color-coated panels. Comprehensively adopt European, American and Japanese standards, and implement strict performance testing, such as: primary physical property testing: film thickness, color difference, gloss, hardness, bending, reverse impact, solvent resistance; secondary physical property testing: corrosion resistance, weather resistance It is an important link to ensure the quality of color-coated panels.

1 one-time physical inspection

A physical property inspection is a test completed in a short time (about 20 minutes) from sampling to test results. In these inspections, the inspection methods for color-coated panels with the same performance are different, and the accuracy of the test results obtained is different.

1.1 Determination of film thickness

There are usually three methods for measuring the film thickness of color-coated sheets: weight measurement method, non-destructive measurement method (electromagnetic method, X-ray method, β-line method), and destructive thickness measurement method (DJH method).

Gravimetric method: Take a 57.3mm×57.3mm square sample, protect the back with tape, weigh (W1), wipe the front with a cotton cloth dipped in CH2CL2 solution, rub off the paint with block white sugar, then wash with water and dry. Blow dry with a hair dryer and weigh (W2).

Calculation formula:

Film weight (gm2) = [mass before film removal (W1) - mass after film removal (W2)]/sample area

This method is time-consuming to measure, but has high measurement accuracy. Non-destructive measurement method: divided into three forms, electromagnetic, X-ray method, β-ray method. The electromagnetic type is to first set the magnetic Thickness Gauge to zero on several different positions of the uncoated metal substrate, and then take three points evenly on the sample to measure the coating thickness, and the sampling point is more than 25mm away from the edge. If it is a hot-dip galvanized substrate, the total thickness of the zinc layer and the coating is measured. The coating needs to be removed with a paint remover that has no corrosion effect on the zinc layer. The thickness of the zinc layer is measured at the same place. The difference between the two is is the coating thickness.

The electromagnetic thickness measurement method is easy to operate and easy to measure, but the measurement accuracy is not high. The X-ray method is usually used to measure the film thickness online. The film thickness measuring instrument is installed behind the finishing coating curing furnace to measure the film thickness at three points on the left, middle and right of the strip steel, take the average value, and adjust the process parameters according to the measurement results to achieve The purpose of precisely controlling the thickness of the coating is to reduce the waste products caused by the thickness of the film not meeting the regulations, and to play a guiding role in reducing production costs. The β-ray method is close to the electromagnetic method, but it is less used.

Destructive measurement of film thickness (DJH method): Use a drill bit with a certain taper to make a pit on the test board that is destroyed to the substrate, place it under a microscope, take 8 points evenly on the edge of the pit, and measure the bottom of these 8 points respectively. Take the average value of the thickness of the paint and topcoat, and calculate the film thickness according to the known angle of the drill bit. The advantage of this measurement method is that it is simple, fast, and highly accurate, and it is the preferred method for judging the coating thickness at present. More points should be taken during the measurement, because the coating on the surface of the coating is not evenly distributed, and its microscopic display is wavy, so the average value of multiple points is taken as the final test result.

1.2 Determination of coating film processing resistance

Bending performance (T-bend) is an important indicator for evaluating the flexibility of coatings. The smaller the T-bend, the better the flexibility of the coating, and the easier it is to process and shape the color-coated board.

There are usually two methods for testing T-bend performance: shaft bending Tester (A method) and bending Tester (B method).

Shaft bending Tester (method A): Take a sample with a width of 50 mm and a length of 100 to 150 mm, put the sample to be tested face down into the instrument, bend the sample by 180° close to the shaft, and check the tightness of the sample. Whether there are cracks on the curved surface, use shafts of different diameters to bend, and find the mandrel with the smallest diameter that does not crack or peel off the bent part. The ability to resist cracking or peeling is expressed by T value: T=minimum shaft diameter/thickness of coated plate. The thickness of the substrate measured by this method cannot exceed 1mm.

Bending test machine (B method): use the body of the sample for continuous testing. That is, insert one end of the sample into the vise, bend the sample and press the bent part of the sample to complete the "0" T bending, continue to make 180° bending, and fold the center with a sample thickness to obtain "1T" bending, and then "2T", "3T"... bending can be obtained, and there should be no obvious gaps in the overlapping parts, so that the minimum T-bend value that prevents cracks or peeling of the coating on the curved part is the T of the coating's resistance to cracking or peeling bend. The thickness of the substrate measured by this method cannot exceed 0.8mm.

The measurement results of method A and method B are basically the same. When measuring with method A, there is a conversion relationship between the minimum shaft diameter/the thickness of the coated plate, which is prone to errors; it is more convenient to measure the T-bend with a bending test machine. more acurrate. At present, domestic coating companies and color-coated sheet manufacturers basically use the B method to measure T-bends.

1.3 Determination of impact resistance of coating film

Reverse impact energy is a dynamic test to evaluate the ability of the coating to resist cracking or peeling under the rapid impact of a heavy hammer. There are usually two detection methods: falling ball type and DuPont type.

Falling ball type: take a sample not less than 75mm×150mm, drop the hammer weight to 1Kg, punch diameter to 15.87mm, place the sample to be tested on the die, let the weight drop from a certain height, each time the height increases 25mm for the test, once cracks appear, do 3 impact tests at the height, slightly lower and slightly higher than the height, each of which is done 5 times to evaluate the level of the crack. The impact area should not be continuously impacted at the same position. The punch hits the sample to form a depression. Use a magnifying glass to check the peeling of the coating. It is suitable for the impact test with minimal deformation of the substrate (substrate thickness is usually less than 1mm).

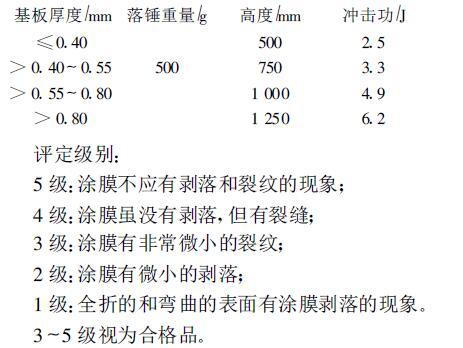

Dupont type: Take a sample not less than 75mm×150mm, drop the weight of the hammer 500±1g, the radius of the impact body is 6.35±0.03mm, and the height of the falling hammer is 500mm, choose different impact energy according to the thickness of the substrate. Grades are rated according to the occurrence of cracks. It is more suitable for impact tests with large substrate deformation (substrate thickness is usually greater than 1mm),

To determine the impact height and thus the impact energy. Errors are easy to occur during the measurement process, and the measurement accuracy is not high; the DuPont method specifies a certain impact energy according to the different thickness of the substrate to evaluate the level of cracks and peeling, and the description of the coating performance is more accurate and intuitive, and the measurement accuracy is higher. The impact energy is small. In Chinese standards, according to the thickness of the substrate, it is divided into two grades (≤0.8mm >0.8mm). The impact energy is respectively specified as 9J and 6J, and it is stipulated that no shedding can occur.

1.4 Determination of hardness of coating film

To evaluate the ability of the coating film to resist scratches, the processing and forming of coiled steel sheets is generally roll forming or stamping forming, so scratch resistance is a very important property of color-coated sheets.

There are usually two methods for testing the hardness of the coating film, namely: pencil hardness and coin scratch test.

Pencil hardness: remove the specified pencil to a length of 5-6mm, grind it flat, make the pencil and the test sample form an angle of 45°, then scratch 6.5mm from near to far, and perform 5 scratch operations in the same area, if it is damaged If there are no more than 3 places, the pencil hardness of this test area can be used as the test result, and the test is carried out in order from high hardness to low hardness. Such as: H※F

※HB※B※2B. Using this method to evaluate the hardness of the paint film is affected by the grade and quality of the pencil. For example, the hardness of the Eagle brand pencil produced in the United States is one specification higher than that of the Mitsubishi brand pencil produced in Japan, and the hardness of the Zhonghua brand pencil in my country is equivalent to that of the Mitsubishi brand pencil. The difference in the quality of pencils of different production batches will also have different effects on the test results. In addition, instruments should be used in the test operation to make the angle of the pencil and the applied force uniform and consistent. In order to reduce the error caused by the experiment.

Coin scratches: Use a one-yuan coin with no frayed edges, hold the coin at an angle of 45° to the test plate, apply a force of 1 kg, move the coin in parallel at a speed of 1 cms, and move the coin at a distance of 2 cm, draw three times in parallel on the same area, The distance between each strip is greater than 5mm, and the test is carried out on three test boards. In the test results, if the substrate is clearly seen in two or more lines, it is judged as "seeing the bottom", and if the substrate is not clearly seen in two or more lines, it is judged as "not seeing the bottom"; if there are two or more of the three test boards "Bottom out" is judged as "bottom out"; if two or more of the three test boards are "bottom out", it is judged as "bottom out".

The coin scratch test is easy to operate and is not limited by the accuracy of the instrument. The disadvantage is that the error of the test result is caused by human operation.

1.5 Determination of coating film solvent resistance (MEK)

Solvent resistance (MEK) is a very important index, which can evaluate the degree of curing and crosslinking of the coating, and directly affects the performance of the coating. The test method is to wrap the finger with rubber finger cot with roving cloth (3-4 layers), dip it in methyl ethyl ketone, then fully squeeze it dry (no solvent dripping is allowed), and immediately use the roving cloth soaked in solvent to test The surface of the sample is rubbed back and forth with force, the back and forth distance is at least 150mm, the friction pressure is moderate, and the speed is about 1 time/second (one back and forth is counted once). Keep the gauze wet throughout the process, and rub until the paint film is damaged or the specified number of times. Check the friction area in the middle area of 125 mm, compare it with the gloss, hardness, and film thickness of the adjacent non-rubbed area, and check whether the gauze has traces of coating peeling off. Pay attention to keep the force even when wiping to reduce the experimental error.

1.6 Chromatic aberration

色差是检验彩涂板和标准板之间的颜色差异,色差值与涂料和工艺控制有关,在生产中通过调整膜厚和固化温度控制该项指标。测量方法通常有两种:目视比色法;色差仪测定法。

目视比色法是指正常视力的人员在天然散射光线下目测检查所制试样与标准板的颜色有无明显的差别,当试样为无光和平光涂膜时,使入射照明光线与被测表面呈45°;当观测有明显镜面反射的试样,调整入射光的角度,消除镜面反射的影响,将样板分别与标准板进行对比。目视比色法比仪器测量更直观,精确,但受观测者的主观因素影响较大。

仪器测定法:通过色差仪在一定的光源下,分别测定样板和标准板的色坐标值,转化成刺激值X、Y、Z,然后按照标准规定的颜色公式计算试样、标准试样的颜色数值,最后比较颜色的差异和变化情况。

色差仪应用在在线检测时,通常安装在出口段的出口活套后面,能及时的测定彩涂板的色差,通过计算机反馈到精涂机控制室,在膜厚的公差范围内调整膜厚来消除这种色差。

1.7 光泽度

涂膜的光泽度是指涂膜表面把投射其上的光反射回来的比率。反射比率愈大,涂膜的光泽愈高。According to试样的表面光泽程度,分别采用20°、60°、80°的入射角测量,中等光泽试样采用60°的角度测量。将测试样板放在光泽度计的底部测量光泽,测试板上如有线状纹路(BrushMark),应使入射角/反射角的轴与该纹路平行后进行测定,这样测定的光泽度比较均匀、准确。

2 二次物性试验

从取样到试验结果需要很长时间完成的试验,是检验彩涂板物化性能方面的试验,也叫二次物性试验。通常是生产厂家检验自己的产品的使用年限而做的试验,不作为交货的According to。

对于建筑用涂层钢板,彩涂板使用性能主要体现在安全性能、居住性能、耐久性能,国外标准更注重彩涂板的应用方面性能,即规定检验彩涂板的耐腐蚀性能、耐候性等项目。

2.1 耐腐蚀性能试验包括盐水喷雾试验、耐潮湿试验等

盐水喷雾试验是将试样放入35℃,5%食盐的喷雾装置中,一定时间后观察涂膜状态的变化,评定平面、切割、弯曲部位的起泡、腐蚀的情况。并评定起泡、腐蚀剥落的级别。

耐潮湿试验用来评估涂层在潮湿环境下贮存时,抵抗起泡及性能劣化的能力。通常将试样在50℃、98%~100%湿度的气氛中放置规定的时间后,检查涂膜表面变化情况。

宜选用空气气氛,采谱条件还取决于同时测定的几个元素和基体成分的综合考虑。

(3)谱处理是从谱中提取以强度表示的每一个指定元素的峰面积,由于定量测定的基础是元素发射线的强度或峰面积,EDXRF的自动数字滤波—最小二乘拟合法可以扣除背景,拨离重叠和测得静的峰强度,这就为优化计数率,降低本底并提高分析精密度提供了保证,它同时也是一种校正方法,主要包括:谱线重叠校正、逸出峰校正、背景校正,这都可以通过分析软件来实现。一般来说,原子系数11~56号元素选用K线。对于强度提取方式GROSS这种最直接的方法,它取能量限内X射线强度的计数总值进行谱处理,感兴趣区的高低限定在峰谷和本底的交界处,这就为进一步扣除本底提供了方便;对于NET,选高底限就更为重要了,因为它是用高低限计数的平均值来扣除本底的,NET适用于峰无重叠而本底值随样品而异的情况,XML用于峰有重叠或需作本底校正的情况,DERIVATIVE除了校正重叠和本底外,还改变参考谱与样品谱之间的峰位。

(4)影响文件的设置,可以确定每个元素计算的校正项,本法中影响系数的计算采用了多元综合回归的方法,适用于校正元素的交叉影响,通过对比校正前后的曲线线性可以得到验证,此功能仅用于强度校正或浓度校正法,而且在设置影响表之前,需要在硬盘中存有标准文件,由于工业硅中含量最高元素是Si,对于其他元素影响甚大,因此标准文件中Si的含量需要标出,影响文件设置时也需要考虑。

(5) The empirical coefficient is obtained through the regression analysis of the standard sample. The regression method is a mathematical statistical method. The calculated correction coefficient has no certain physical meaning. Its accuracy mainly depends on the number of standard samples. Quality of intensity and concentration data. Therefore, it is necessary to have a sufficient number of standard samples and accurate regression data when calculating the calibration coefficient. During the calibration process, the selection of calibration items should be based on factors such as the concentration distribution of the standard series, the difference in mass absorption coefficient, and the cross-effect between elements. Introducing too many correction items will lead to excessive correction and cause greater analysis errors.

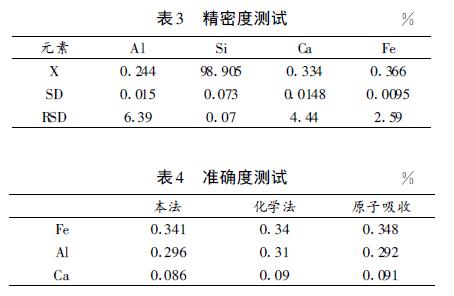

(6) Precision and accuracy test

The same sample was used to make 8 samples for precision testing at different times. The results are shown in Table 3. It can be seen that the precision of Si is slightly worse than that of other elements. It may be that Si is obtained by subtraction method, which cannot be completely different from the actual value. coincide, but small differences have little effect on other elements. The accuracy test is shown in Table 4.