Determination of flexibility

This method is applicable to the determination of the flexibility of the coating film, which is expressed by the diameter of the smallest shaft that the sample bends on shafts of different diameters without causing coating damage.

Flexibility Measurement Equipment

The flexibility Tester, the flexibility Tester is composed of 6 steel shaft rods with different thicknesses, fixed on the base, and the base can be fixed on the Tester with screws.

On the side of the test bench.

The shaft dimensions are as follows:

Each mandrel is 35 mm long

Shaft 1: 10 mm in diameter

Shaft 2 : section 5 mmX10 mm, radius of curvature 2.5 mm

Shaft 3 : section 4mmX10mm , radius of curvature 2mm

Shaft 4 : section 5mmX10mm , radius of curvature 1.5mm

Shaft 5 : section 2 mmX10 mm, radius of curvature 1 mm

Shaft 6 : section 1 mmX10 mm, radius of curvature 0.5 mm

4x magnifying glass.

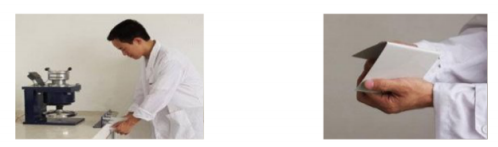

Flexibility Determination Method

Test under the test conditions of 23±2°C and relative humidity of 50±5%.

Use both hands to press the sample tightly on the shaft rod with a diameter specified in the product standard, and bend it around the rod. When bending, the thumbs of both hands should be symmetrical to the center line of the shaft rod. The bending action needs to be completed within 2-3 seconds. After the coating film is bent, observe it with a 4 times magnifying glass. If there are cracks and peeling off, it is unqualified.