1. According to the standard:

"Unified Standard for Construction Quality Acceptance of Construction Engineering" GB50300-2001

"Code for Construction Quality Acceptance of Steel Structure Engineering" GB50205-2001

2. Construction preparation

2.1 Materials and main equipment:

2.1.1 Fireproof coating: products identified by the competent department and approved by the local fire department must be used. For example, the ST1-A fireproof coating used in the XX building has been appraised by the Sichuan Fire Research Institute of the Ministry of Public Security and approved by the Beijing Fire Bureau. Before use, check the approval documents and check the factory certificate in batches of 100t. Technical performance should meet the requirements of relevant standards;

2.1.1.1 The fire resistance test shall be sampled once every 1000t by the fire department, and sent to the National Fire Resisting Component Quality Supervision Center for inspection, and its fire resistance limit shall meet the design requirements.

2.1.1.2 Adhesive strength and compressive strength shall be sampled every 500t and sent to the National Chemical Building Materials Testing Center for inspection. The adhesive strength and compressive strength shall be greater than the technical specifications.

2.1.2 High-strength adhesive and steel anti-adhesive are supplied by the manufacturer and used according to the instructions.

2.1.3 Steel wire mesh, steel sieve card, plastic cloth, etc.

2.1.4 Main machinery and tools: mixer, mortar pump, steel mesh scissors, shovel, trolley, measuring container, steel needle with scale, steel ruler, etc.

2.2 Operating conditions:

2.2.1 The approved construction unit shall be responsible for the construction and check the qualification approval documents.

2.2.2 Base treatment: effectively remove dust, floating rust and oil on the surface of steel components.

2.2.3 The damaged or missing parts of steel components should be repainted with anti-rust paint twice, and spraying is allowed after inspection and acceptance.

2.2.4 Clean up the operating site before spraying, and protect it with plastic sheets near doors, windows, partition walls and other parts.

2.2.5 Fix the steel wire mesh: cut the steel wire mesh according to the shape of the component, fix it on the steel component with ф6 steel bars, and leave a gap of 5-10mm between the steel wire mesh and the steel component.

3. Operation process

3.1 Process flow:

Operation preparation → batching and mixing of fire retardant coating → spraying → inspection and acceptance.

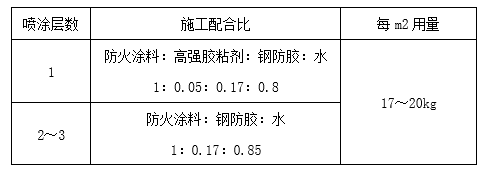

3.2 Ingredients and mixing of fireproof coatings: Powdered coatings should be prepared as they are used. The ratio of ST1-A type is as follows

When stirring, first pour the paint into the mixer, add water and mix for 2 minutes, then add adhesive and steel anti-glue and stir for 5-8 minutes to make the consistency reach the sprayable level.

3.3 Spraying:

3.3.1 The general design requires that the thickness is 1.2 times the thickness of the fire resistance limit after the fire resistance test. The fire resistance limit is 2h for the beam and 3h for the column, and the design thickness is 30mm for the beam and 35mm for the column. The thickness of the first layer is about 1cm, dry 70% to 80% before spraying the second layer, the thickness of the second layer is about 1 ~ 1.2cm is appropriate, dry 70% to 80% before spraying the third layer, until the third layer reaches the required thickness.

3.3.2 When spraying, the Spray Gun should be perpendicular to the steel member to be sprayed, and the distance is 6-10cm. The spraying air pressure should be kept at 0.4-0.6MPa. After spraying, self-check should be carried out, and the part with insufficient thickness should be sprayed again.

3.3.3 Before the formal spraying, a building layer (section) should be sprayed for trial, and after passing the verification by the fire department and the quality supervision station, the large-scale operation should be carried out.

3.3.4 Construction shall not be carried out when the construction environment temperature is lower than +5°C. Measures should be taken to seal the periphery and heat up. It is advisable to keep the temperature above +5°C for 48 hours before and after construction.

3.4 Inspection and acceptance: After spraying a building layer and passing the self-inspection, the construction records will be sent to the general contractor for joint inspection by the general contractor, subcontractors, and Party A (supervisor). Check the thickness with a steel needle with a scale. If the thickness is found to be insufficient, re-spray or shovel and re-spray. Check the empty drum by hitting it with a hammer, if it is found that the empty drum should be re-sprayed. After passing the pass, go through the concealed project acceptance procedures.

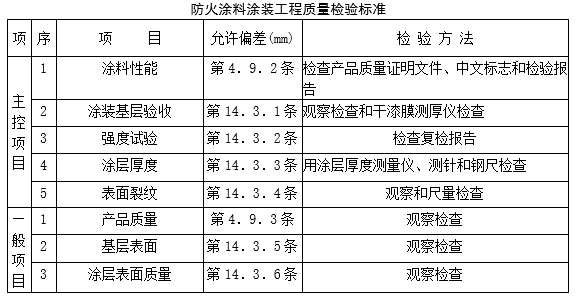

4. Quality standards

5. Finished product protection

5.1 Prevent collision damage: The strength of the fire retardant coating is still not high after hardening, and the parts that are prone to collision during construction should be temporarily protected to reduce damage.

5.2 Anti-pollution: Protect the semi-finished product before spraying, especially wrap the parts near the spraying with plastic cloth.

6 quality problems that should be paid attention to

6.1 Empty drum: First of all, the mix ratio should be strictly controlled. The key is to clean the base layer, and pay attention to the bonding strength of raw materials in batches.

6.2 Cracks: The ambient temperature and humidity should be appropriate, and the ventilation and drying time should be mastered during layered spraying.

6.3 Uneven thickness: When spraying, the angle of the nozzle should be perpendicular to the surface of the component, and the distance should be appropriate. There should be a certain time interval between the spraying of each layer, and it should not be too tight.

7. Quality records

7.1 Fireproof coating material quality certificate and inspection report.

7.2 Concealed project acceptance records.

7.3 Coating inspection data.

7.4 Sub-project quality inspection and assessment.

7.5 Design changes and negotiation records.