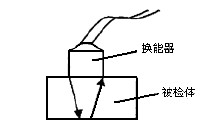

The basic measurement principle of the ultrasonic pulse echo method is shown in the figure. Mainly based on pulse echo technology, it is suitable for thickness measurement of various materials that can make ultrasonic waves propagate inside at a constant speed and can be reflected from the back.

Schematic diagram of the measurement principle of the pulse reflection ultrasonic Thickness Gauge

However, the accuracy of the pulse echo method is poor. Even for metal materials such as castings, especially cast iron and stainless steel, if there is a structure of coarse grains inside, the ultrasonic waves will be strongly scattered, and the penetration depth will drop sharply. According to this topic The structural characteristics of the radar absorbing material in the paper, the adhesive (soft material for ultrasonic waves) contains a certain amount of absorbent (such as light-based iron powder, polycrystalline iron fiber, ferrite, etc.), the absorbent and The impedance of the binder to the sound wave is quite different, and the absorber will produce chaotic reflection (scattering) of the sound wave, causing many chaotic reflections in the main detection period, affecting the measurement of the sound wave, easily causing misjudgment, and even unable to read the value correctly. For samples with rough surfaces, due to the influence of scattering, the readings will also change irregularly, or even have no readings in extreme cases.

In addition, since the absorbing coating contains more than 90vol% of the binder, the binder is a flexible material with strong attenuation to sound waves (other flexible materials such as soft plastics, rubber, waterproof glue, etc.), ultrasonic waves are used to Measuring its thickness is generally more difficult. If ultrasonic waves are used to measure the thickness of such flexible materials, the main improvement measure is to increase the ultrasonic intensity. However, the increase of the intensity will inevitably increase the ultrasonic pulse width, resulting in a decrease in resolution and an increase in clutter, which is prone to misjudgment and cannot detect thicknesses below 2mm, so there is not much practical value.

Ultrasonic waves cannot penetrate unbonded spaces, and it is impossible for ultrasonic Thickness Gauges to measure unbonded laminated materials. Ultrasonic waves cannot propagate at a uniform speed in composite materials, and instruments that use the principle of ultrasonic reflection to measure thickness are not suitable for measuring laminated materials and composite materials. Therefore, the pulse echo method is difficult to apply to the thickness measurement of absorbing coatings in laminated and composite structures.