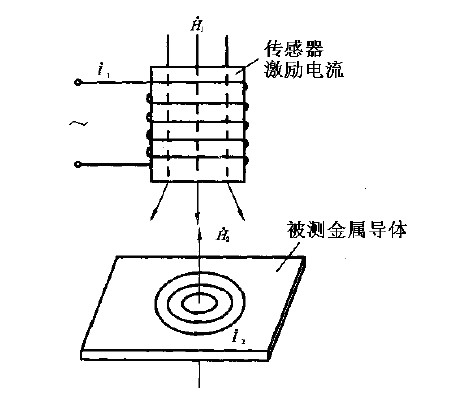

The basic working principle of the reflective eddy current coating Thickness Gauge is that when the measuring head is in contact with the tested sample, the high-frequency electromagnetic field generated by the measuring head device will cause the metal conductor placed under the measuring head to generate eddy current, and its amplitude and The phase is a function of the thickness of the non-conductive coating between the conductor and the probe, that is, the alternating electromagnetic field generated by this eddy current will change the probe parameters, and the size of the probe parameter variables depends on the thickness of the coating. By measuring the size of the probe parameter variable and converting the electrical signal, the thickness value of the measured coating can be obtained. Its measurement principle diagram is shown in the figure below:

Schematic of the eddy current sensor

NBCHAO Mall believes that this method can adapt to the nature and use characteristics of the absorbing coating itself, and can be used to measure the thickness of the absorbing coating. However, it is pointed out in the literature discussing this method that the measurement results within the allowable error range can only be obtained after a complex calibration process for coatings with different electromagnetic parameters. The thickness of the sample to be measured is less than 1 mm, about 0.5 mm, and the measuring range is small, so this method is difficult to obtain practical application.

Further analysis found that all magnetic methods (including variable reluctance method and eddy current method) require the coating to be non-magnetic coating, and no coating thickness measurement products using this method have been found for magnetic coatings. In the national standard GB/T4957-85 "Eddy current method for measuring the thickness of non-conductive coating on non-magnetic metal substrate" (corresponding to the international standard IS02360-1982), the standards, operating procedures and factors affecting the measurement accuracy of the eddy current Thickness Gauge and its precautions are described in detail.

The clauses concerning the factors affecting the measurement accuracy should be regarded as the guiding documents to be followed in the development and application of the eddy current coating Thickness Gauge. The main factors affecting the measurement accuracy include

. The thickness is approximately proportional;

2) The conductivity of the base metal has an impact on the measurement, which is related to the composition of the base metal material and the heat treatment method;

3) Any kind of Thickness Gauge requires the base metal to have a critical thickness, only if it is greater than this thickness, The measurement will not be affected by the thickness of the base metal;

4) The eddy current Thickness Gauge has an edge effect on the determination of the sample, that is, it is unreliable for the measurement near the edge of the sample or at the inner corner;

5) The curvature of the sample does not affect the measurement 6) The surface roughness of

the base metal and the covering layer affects the measurement accuracy, and the increase of the roughness increases the influence;

7) The eddy current Thickness Gauge has an effect on the obstruction The attachment substance in close contact between the probe and the surface of the covering layer is sensitive, so the dirt on the surface of the probe and the covering layer should be removed before measurement; the probe should be kept in constant pressure vertical contact with the test surface during measurement.

Among these factors, (1) (5) (6) (7) are problems that will be encountered in this project and need to be considered emphatically. In addition, the most prominent feature of this topic is that the wave-absorbing coating is different from the general covering, (1) it has strong ferromagnetism, and its magnetic permeability has a significant impact on the coil impedance; (2) it has a strong influence on the AC The variable magnetic field will also have eddy current loss, and its influence is also large and cannot be ignored. Moreover, both influences are directly related to the thickness of the coating, and it is difficult to find out the mathematical relationship between the thickness of the coating and the probe parameters. Therefore, this method is also difficult to be used in the detection of the thickness of the magnetic wave-absorbing coating in this subject.