The purpose of the bending test of the coating is to detect the flexibility of the film layer. It is one of the important items to evaluate the physical properties of the color-coated steel plate coating by measuring the anti-opening or anti-stripping ability of the coating when the sample is bent.

The shape of many substrates to be coated has certain deformability, so the coating is also required to have corresponding flexibility. In the bending test of the cured coating, the sample is bent 180° around itself and folded in half, and then a transparent tape is pasted along the curved surface, and the tape is pasted flat while removing the bubbles, and then it is quickly torn off along the bend at 60° Adhesive tape, visually observe whether the curved surface of the coating is cracked or peeled off (the peeling of the coating within 10mm from the edge is not counted). Determine the minimum multiplier value of the test piece that will not cause the coating to crack or peel off.

When the flexibility is good but the adhesion is not good, the bending test may cause the coating to peel off the substrate; when the flexibility is poor and the adhesion resistance is good, the bending test may cause the coating to crack. In addition to the coating formula itself determining the flexibility of the cured film, the degree of curing also affects the degree of polymerization and crosslinking, that is, when the temperature is overheated, the flexibility decreases. Generally speaking, the hardness and flexibility of the cured coating film are contradictory, that is, the increase of hardness is often at the expense of flexibility.

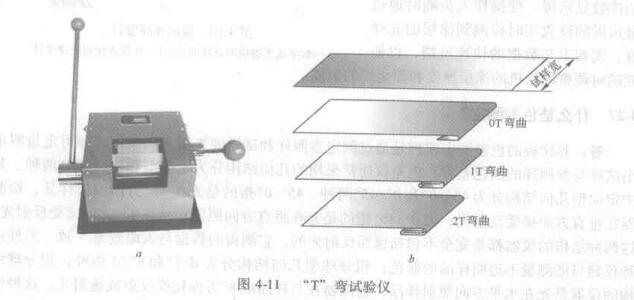

The "T" bending test method usually uses a special Tester (see Figure 4-11a), which stipulates that when the thickness of the substrate is not greater than 0.8mm, it is bent at 180°; when the thickness of the substrate is greater than 0.8mm, it is bent at 90°. When 180°bending is adopted, after the sample is bent 180° around its own edge, the minimum thickness multiple of the sample that prevents the coating from cracking or peeling off (such as 0T, 1T, 2T, 3T..., see Figure 4-11b) shows the test results; and when the 90°bending is adopted, after the sample is bent at 90°, use the tape method to check whether the coating on the curved surface of the sample is peeled off, or use a magnifying glass to hang the sample bending The top coat is free of cracks.