feature

feature

Minimum mode, which can continuously display the minimum thickness measurement value.

Handheld and lightweight (950g).

Few buttons, easy to operate.

Backlit LCD display with easy-to-read large-character numerals.

Fast thickness measurement, can measure 16 thicknesses per second.

The minimum thickness value at small bends can be obtained.

Easy to measure the center of large workpieces.

Measurement accuracy is independent of the shape or properties of the material being measured.

Built-in file-based data logger that can store up to 95,000 thickness measurements.

Accurate Thickness Gauge

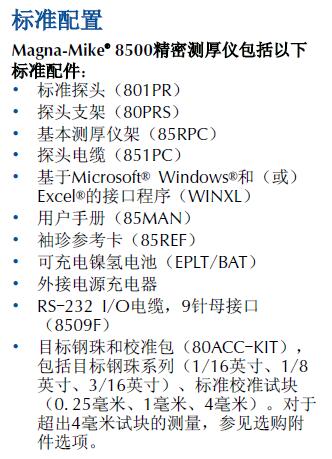

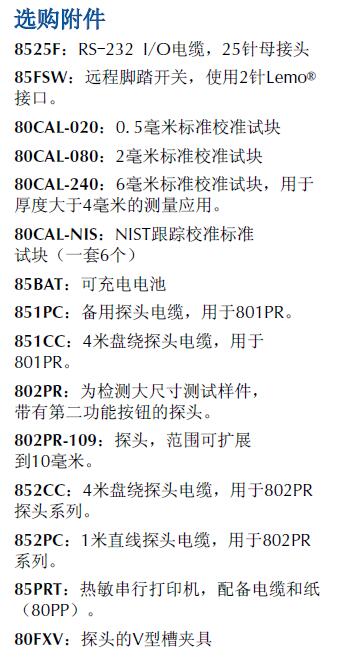

The Panametrics® Magna-Mike® 8500 is a handheld Thickness Gauge that uses magnetism to make reliable, repeatable measurements on nonferrous materials.

Operation of the Magna-Mike 8500 is very simple. When measuring, place the magnetic probe on one side of the material to be tested, and place a small steel ball on the other side. A Hall Effect sensor built into the probe measures the distance from the probe tip to the target ball. The measured thickness value is then displayed on the screen in an easy-to-read digital readout.

plastic bottle

In applications like the measurement of plastic containers, the operator only needs to put a small target steel ball into the container, and the magnetic probe outside the container will attract the target steel ball.

As the operator moves the probe along the outer surface of the vessel, the target ball moves with the probe. In the minimum mode, the Thickness Gauge will continuously display the current thickness value and the minimum thickness value.

other applications

For parts with special shapes and sizes that are difficult to measure

parts, the Magna-Mike® 8500 is a Thickness Gauge you can count on. Its non-destructive measurement function can accurately measure the thickness value of fillets or grooves with a radius close to 0.7950mm. Magna-Mike 8500 has been successfully

It is widely used in quality control projects of glass containers, aluminum containers, aerospace composite parts, medical packaging, automotive panels, airbag tear seams, and other non-ferrous parts.

feature

feature