1. Light transmittance and haze detection

Transmittance

Light transmittance refers to the ratio of the luminous flux passing through the sample to the luminous flux incident on the sample, expressed as a percentage.

Haze

Haze refers to the ratio of the scattered luminous flux that passes through the sample and deviates from the incident direction to the projected luminous flux, expressed as a percentage.

Detection method:

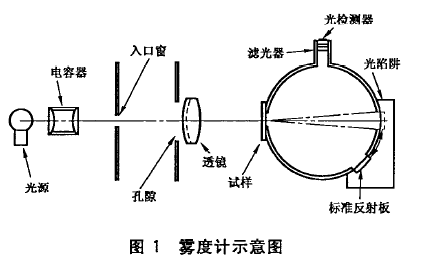

1. Haze meter method - see the following schematic diagram

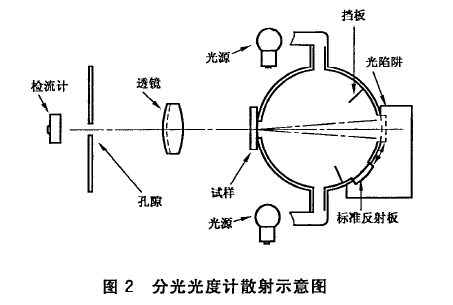

2. Spectrophotometer method - see the following schematic diagram

2. Shore hardness test

Shore hardness in GB/T2411-2008, ISO868:2003, GB/T531.1-2008, GB/T2411-2008

1. The Hardness Tester is mainly divided into type A and type D

2. The thickness of the sample is at least 4mm, and several thinner layers can be stacked to form the required thickness. Due to incomplete surface contact between the layers, test results may differ from those obtained on single-sheet specimens.

GB/T531.1-2008 "Vulcanized Rubber or Thermoplastic Rubber" stipulates the test method using the following scales:

A scale, D scale, AO scale, AM scale

Using the Shore Hardness Tester, the scale selection is as follows:

1. When the D scale value is lower than 20, select the A scale;

2. When the A scale value is lower than 20, select the AO scale;

3. When the A scale value is higher than 90, select the D scale;

4. For thin samples (thickness of the sample is less than 6mm), use the AM scale.

thickness

When using Shore A, D and AO Hardness Testers to measure the hardness, the thinnest thickness of the sample is 6mm, while using the Shore AM Hardness Tester to measure the hardness, the minimum thickness of the sample can reach 1.5mm.

For thin slices with a thickness of less than 6mm and 1.5mm, in order to obtain sufficient thickness, no more than 3 layers can be stacked. For Shore A, D and AO Hardness Testers, the total thickness of the sample after stacking is at least 6mm; for AM type, the total thickness of the sample after stacking is at least 1.5mm. However, the results determined by laminated samples may not agree with the structure determined by single-layer samples.

If used for comparison purposes, the specimens shall be similar.

In addition, for soft rubber, it is recommended to use a thin sample for measurement, and a higher hardness value will be obtained due to the influence of the bracket table.

surface

Another requirement for the size of the sample is to have enough area so that the measurement position of the Shore A-type and D-type Hardness Testers is at least 12mm from any edge, respectively, 15mm for the AO type, and at least 4.5mm for the AM type. The surface of the sample is flat within a certain range, parallel up and down, so that the presser can contact the sample in a sufficient area. The contact surface radius of Shore A-type and D-type Hardness Testers should be at least 6mm, AO type should be at least 9mm, and AM type should be at least 2.5mm.

Spring test force retention time

Add the spring test force according to the regulations to make the presser foot closely contact with the surface of the sample. When the presser foot is in close contact with the sample, take a reading at the specified time. The standard spring test force retention time for vulcanized rubber is 3s, and for thermoplastic rubber it is 15s.

If other test times are used, it shall be stated in the test report that the unknown type of rubber is treated as vulcanized rubber.