The scratch test of color steel plate is mainly used to evaluate the adhesion between the primary coating of the sample and the substrate or the ability of the coatings to resist separation from each other in the multi-coat layer system.

The scratch test of color steel plate is mainly used to evaluate the adhesion between the primary coating of the sample and the substrate or the ability of the coatings to resist separation from each other in the multi-coat layer system.

Adhesion is one of the most basic indicators for evaluating coating quality. At present, the cross-cut method is mostly used in the domestic color coating industry. The cross-cut test is usually carried out according to the national standard with a cross-cut Tester (Figure 4-16). When adopting a cross-cut coating, the following test technical requirements are required: the distance between the blades is: coating For samples with a thickness of 0-50 μm, use a cross-cutting instrument with 11 blades, and the distance between the blades is 1mm, and draw 11 parallel cutting lines in a steady manner; for samples with a coating thickness of 50-125 μm, use The cross-cutting instrument with 6 cutting edges, the distance between the blades is 2mm, and draws 6 parallel cutting lines in a steady manner. Then cross the original cutting line at an angle of 90° to draw 11 or 6 parallel cutting lines to form a grid pattern, and finally adhere to the coating with No. 600 adhesive tape, and then use a 60° Angular force quickly pulls off the tape to verify that the coating has peeled off the substrate.

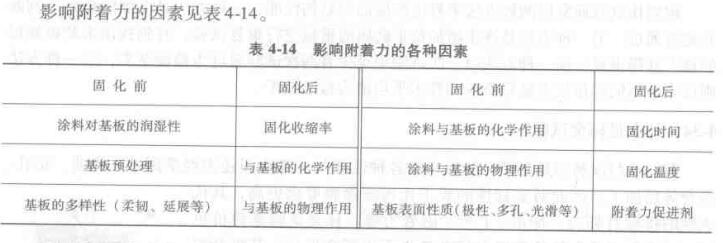

The coating adhesion is mainly determined by the properties of the coating formulation, but the cleanliness of the substrate surface can also seriously affect the coating adhesion, especially when there are release agents such as oil, paraffin, silicone oil, and silicone additives on the surface of the substrate. The polarity is very weak, and it hinders the direct contact between the paint and the substrate surface, and the adhesion will be seriously reduced. Therefore, surface treatments such as degreasing and cleaning of substrates, which are strictly controlled, can greatly improve adhesion. Only by enhancing the surface polarity can the adhesion of the paint be ensured.

The evaluation of the results of the cross-cut test in my country's color coating industry is mostly based on the comparison of the surface damage state after the coating is cut and torn off with an adhesive tape and the "test result classification" in the national standard GB/T13448-2006. Surfaces are graded according to six grades of 0, 1, 2, 3, 4, and 5.

The cross-cut Tester has a variety of specifications (6 blades, 11 blades) on the market in CHINA, and users can choose and use them reasonably according to their own test needs and technical standards.