Why do you need to verify

Statutory inspection, user routine inspection.

The Rotational Viscometer uses a beryllium-copper alloy spring and a supporting mechanism to complete the operation of the principle of the rotational torque of the rotor in the liquid. The twisting degree of the spring measured by the sensor is proportional to the viscosity of the liquid. However, these memory metals will also fatigue with the passage of time, which will change the measurement state of the instrument, so inspection is required.

purpose of verification

Check the degree of deviation of the Rotational Viscometer from the normal value to judge the degree of wear of the Rotational Viscometer. This calibration is of the nature of inspection and cannot be adjusted by the user. This is different from the calibration of an electronic balance.

Standards used:

Dongnan Keyi can provide viscosity standards that meet the NIST standards of the United States, which are divided into two categories: room temperature and high temperature standards. The nominal viscosity values of commonly used room temperature standards at room temperature (25C) are: 5, 10, 50, 100, 500, 1000 , 5000, 12500, 30000, 60000, 100000. Its specific gravity is between 0.92-1.00, and there is a correction value between the actual viscosity and the nominal value of each standard product, so the actual viscosity is near the nominal viscosity , is indicated in the label.

The selection principle of the standard is to choose the viscosity standard closest to the viscosity of the sample to be measured.

When using standard products, care should be taken to avoid possible dilution and contamination of standard products, and it is better not to reuse them. Cover and seal them in time after taking them.

Viscosity is a physical quantity parameter that is very sensitive to temperature. A small change in temperature may cause a considerable deviation in viscosity. Therefore, it is very important to keep the temperature stable during viscosity measurement, especially during calibration. Therefore, it is necessary to use a constant temperature circulating Water Bath. of.

Calibration operating procedures

1. Preparation of constant temperature conditions for viscosity measurement vessels;

2. Select the combination of rotor and speed according to the operation rules of the instrument. Each combination of rotor and speed forms a full scale range (measurement range); the principle of combination selection is to make the viscosity of the standard product within 50% of the full scale. %, the range less than 10% of full scale and greater than 90% is inappropriate. No.) combined with high rotation speed can get approximately the same measurement range, but in order to avoid eddy current at high speed and make the measurement results unstable and reduce the wear of the instrument, the combination of small rotor and low speed should be selected as much as possible.

3. Determine the standard product according to the conventional measurement method, and read the viscosity data.

4. Judging the stability, reproducibility and value of the data.

Criteria for judging the status of the instrument

Generally, with a new instrument or a well-adjusted viscometer, at a constant temperature (25°C), the measured value obtained by selecting a suitable combination of rotor and rotational speed should be equivalent to the nominal value, and the error should be within 3%. If the error is greater than ±10%, the viscometer cannot be used and needs to be repaired or adjusted.

Brookfield (Bo Lifei) LVDV-1+ rotary viscometer operating procedures and precautions

Overview:

American Brookfield Rotational Viscometer, as the universal standard viscometer in the world, has been widely used in CHINA. It is generally divided into pointer type and digital type. Among them, the pointer type is divided into three types of high viscosity, medium viscosity and low viscosity, and the digital type is also divided into three types of high viscosity, medium viscosity and low viscosity. LVDV-1+ belongs to the digital 1 type rotary viscometer (low viscosity), which can directly display four kinds of information, such as viscosity value, rotor number, speed and percentage, on the LCD screen. Its application range is: 15cP~2,000,000cP (centipoise), equipped with 4 rotors, with 18 speeds to choose from, which can be divided into 72 measurement ranges. The BROOKFIELD Rotational Viscometer also has a C/P measurement system, ultra-low Viscosity sample and small sample measuring system, up and down reciprocating measuring system and other accessories.

BROOKFIELD Rotational Viscometer is represented by Southeast Keyi in CHINA and provides technical services.

Operating procedures:

1. After the instrument is installed, place it on a stable table, and rotate the three screw feet at the bottom to make the air bubble in the level at the top be in the center, and the instrument is leveled.

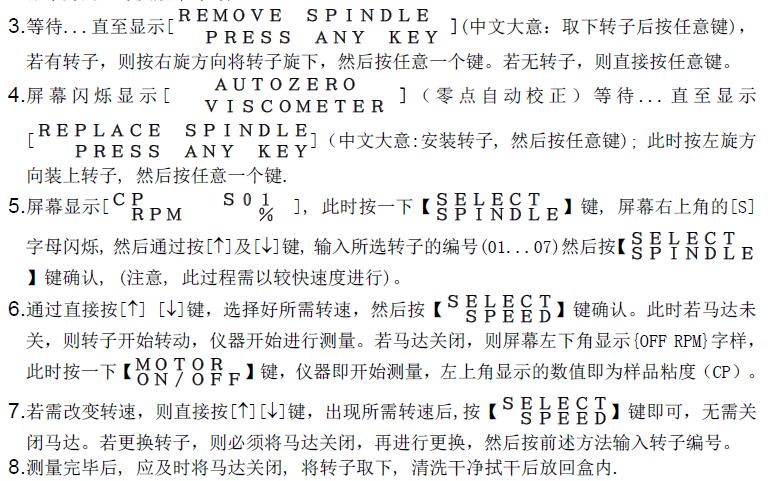

2. Turn on the power (220V50HZ), turn on the power switch on the back of the instrument, the display will light up and display a series of information (such as the model and version number of the instrument itself, etc.).

3. Precautions and instructions

1. For this type of viscometer, each group of determined rotors and rotational speeds corresponds to a determined measurement range, that is to say, 6 rotors, coupled with 18 rotational speeds, have a total of 6×18=108 ranges. The smaller the rotor volume, The lower the speed, the larger the corresponding range. On the contrary, it will be smaller. In the actual measurement process, if the viscosity of the sample is greater than the current range, the upper left corner of the screen will display the word [OUTOFRANGE]. At this time, you need to reduce the rotation speed, or choose a rotor with a smaller volume, until you can measure .

2. It should be pointed out that the percentage in the lower right corner of the screen indicates the percentage of the measured value in the current full-scale value. The manufacturer stipulates that when the value is between 10% and 90%, the reading can be read, otherwise it is invalid .As a supplier, we suggest that users can adjust the value to 40-60% before reading. The method is as follows. When the percentage is lower than 40%, it means that the current range is too large. If the speed is high or a rotor with a larger volume is replaced, the percentage will increase until it is required. On the contrary, if it exceeds 60%, then the speed is reduced, or a rotor with a smaller volume is replaced, and the percentage will be reduced until it is required. You can read the value (CP) in the upper left corner of the screen.

3. Try to avoid long-term high-speed rotation of the instrument (such as 100 rpm). The purpose of changing the measuring range can be achieved by replacing the rotor. That is to say, although the combination of a large rotor (small rotor) at a low speed The same measurement range can be obtained by using a combination of a small rotor and a high speed, but in order to avoid the eddy current generated by the high speed and make the measurement result unstable and reduce the wear of the instrument, the combination of a small rotor and a low speed should be selected as much as possible. is an important principle.

4. When replacing the rotor, pay attention to fix the upper end of the connecting part with one hand first, and then screw on or off the rotor.

5. Be careful to use the rotor, don't get dirty, bend eccentrically, and avoid scratching the surface.