1. To keep the nickel plating solution stable, first of all, the six gates must be well

(1) Check the craftsmanship. Special attention should be paid to the quality of the pre-treatment process.

①Pay attention to the removal of polishing paste on polished parts. After the plated parts are mechanically polished, solid . Simply soaking in a wax remover is not easy to remove effectively in a short time. If you dig it with a knife first, and then use a remover Soaking in wax is much easier.

② Pay attention to the degreasing and derusting work of the plated parts. The degreasing and derusting workpieces can be transferred to the next process .

③ Pay attention to the cleaning of the plated parts before entering the tank. The last cleaning before nickel plating is very important, especially for the plated parts with complex geometric shapes , such as interlayers, slits, blind holes and parts that are easy to fill with water on many sides, rinse with running water, and then rinse after turning the direction of . After rinsing, use methods such as shaking off surface adsorbed water to effectively clean.

④Pay attention to the water quality of cleaning water. Multi-tank countercurrent rinsing should be used as much as possible.

(2) Keep the materials closed. In addition to the purity requirements of chemical materials, attention should also be paid to the quality and use of anode materials.

use method.

① Selection of anode material varieties. The author tends to use rolled anodes based on experience. Rolled anode has the advantages of uniform dissolution, high purity and high utilization rate.

② Anti-nickel slime measures. It is more appropriate to wrap the anode with cloth, usually with two layers of cloth.

③Clean the nickel anode frequently.

④ Anti-nickel anode passivation measures. According to the test results, if the chloride is insufficient, it should be replenished in time. If the anode area is too small, the bandage is too thick, etc., corresponding measures should be taken to solve it.

⑤ Prevent the anode hook from contacting with the solution. The anode hook needs to be more than 10cm above the liquid level. In order to prevent the hook from being corroded and polluting the solution, the non-conductive part of the hook should be coated with insulating glue for protection.

(3) Turn off the solution preparation (supplement).

①Strictly abide by the solution preparation and material addition process. Such as sodium lauryl sulfate, boric acid and other dissolution preparation methods.

②Prevent overfeeding. Every time the solution is adjusted, it must be based on the test data, and the addition amount must be carefully calculated and recorded in the resume card of the bath solution for future reference.

(4) Control the environmental sanitation of the workshop. The environmental conditions of the electroplating workshop will be directly related to the maintenance of the solution, and protective measures should be considered according to the specific conditions, such as dust prevention and harmful gas intrusion prevention. If the chromium plating is separated from the nickel plating to prevent the chromium mist from invading the nickel plating solution, the plating tank should be equipped with a tank cover, which can prevent the intrusion of harmful gases and solid particles.

(5) Turn off the use of the hanger.

① Before use, check in detail whether the insulation part is damaged.

②Do not use the hanger with too thick coating.

③ Do not use mixing racks.

(6) Keep daily maintenance off.

①Regularly suction and filter the sludge accumulated at the bottom of the tank. After a certain amount of sludge accumulates at the bottom of the tank, the plated parts will float up due to the agitation of the solution when they enter and exit the plating tank , and will be adsorbed on the plated parts, causing burrs to appear on the coating. Adopt methods such as setting an isolation layer at the bottom of the plating tank , the sludge is easier to absorb, suck once a week, and suck out 30-40L solution containing sludge at the bottom of the tank each time in a plastic basin , and then slowly remove it after it settles. The filtration does not affect production or waste materials, and can effectively purify the solution .

②Use a magnet to fish out the plated parts in the drop tank every day after get off work.

③ Remove the oil on the liquid surface in time. Use rough paper (absorbent paper without filler is better) to drag the bath liquid surface to absorb the thin oil film on the liquid surface.

④ Prevent mutual infection between tools. There are many things to pay attention to in this aspect, such as: weighing pan for weighing materials , stirrer for stirring solution, magnet for sucking plating parts, iron hook for pulling plating parts in solution, filter cloth, etc. It should be specified for special use , and the tools must be carefully cleaned before and after use.

Preventing the nickel plating solution from being polluted is the key to ensuring the quality of the coating and reducing the production cost in the electroplating process. To do this work well requires full mobilization, participation by all, and civilized production in order to improve the existing process level one step .

2. The passivation of the bottom layer of nickel causes the gold plating layer to break out

Gold plating used to use silver as the bottom layer, but it was found that silver is easy to oxidize and turn black, and it leaks out through the pores of the gold plating layer, affecting the appearance of the gold plating layer. Now many use nickel as the bottom layer instead. Although this phenomenon of black spots on the gold layer has been effectively solved , the problem of the bonding force of the gold-plated layer on the nickel layer occurs from time to time. Some are puzzled. In fact, the poor adhesion is mainly due to the lack of gold plating immediately after nickel plating. The nickel layer is oxidized after being exposed to the air for too long. This phenomenon can be completely avoided if gold is plated immediately after nickel plating .

In order to avoid the recurrence of gold-plated layer skinning, the number of plated parts and the length of each series of workpieces should match the gold-plating tank during nickel plating (because the general unit gold-plating tank is smaller than the nickel-plating tank). Although the remaining workpieces can be soaked in clear water to be activated before the gold plating in the lower tank and then plated, the effect is still not as good as that of gold plating immediately after nickel plating.

3. Failure caused by nickel plating solution being polluted by galvanized pipe

A factory accepts a batch of copper, nickel, and chromium electroplating tasks for workpieces bent from galvanized steel pipes. During the electroplating process, due to the lack of production knowledge of the operators and the lack of professional technicians in the workshop to check the process, resulting in Serious consequences of contamination of the nickel plating solution with zinc occurred

The workpiece should be degreased and derusted before polishing and polishing, but the factory did not do this. It mistakenly believed that the surface of the workpiece was galvanized and it was very clean. Carry out grinding and polishing directly , and feel that the surface of the workpiece is very clean when it is transferred to the electroplating process after grinding and polishing, so it is directly washed with lime slurry , and copper, nickel, and chromium are plated after a short period of weak corrosion.

The zinc layer inside the pipe has never been in direct contact with acid or alkali and remains in its original state. After entering the nickel plating bath, the zinc layer becomes active in the weakly acidic solution. However, due to the weak acidity, the reaction is slow. Although there are bubbles, they have not been detected.

After the finished product is plated in multiple slots, black stripes gradually appear on the nickel layer, and the scaly nickel layer falls off. But at this moment, the operator is still unaware of the fact that the nickel plating solution has been seriously polluted by zinc ions, and is still looking for the reason in the process conditions.

The author was invited to participate in the discussion of the failure. From the analysis of the surface of the nickel layer, it was likely that the solution was contaminated by zinc ions . However, at this time, the factory was skeptical because chemical materials had been added to the nickel tank recently. It is also impossible for zinc to be brought into the plating of these pipe fittings, but the author always believes that the contamination of the nickel plating solution may be related to the plating of this batch of pipes. Because this batch of pipe parts is made of galvanized steel pipes, although the zinc layer on the outer surface of the pipes must have been worn out, the inner wall of the pipes still retains the original galvanized layer. Moreover, due to the needs of the pipe bending process, the original zinc layer is still piled up. Because , in the process of bending the pipe to form a workpiece, it is necessary to fill the pipe with sand, and then simmer it in a stove after filling it firmly, so that it will not be squeezed during the bending process and maintain the original shape of the pipe. However, during this process, the zinc layer inside the pipe has melted and condensed with the sand particles in the pipe to form no small lumps, and the zinc layer on the inner surface is no longer the original thickness of a few microns . It takes a long time to corrode to remove. Later, an experiment , and it was confirmed that the bubbles would stop escaping after being corroded in concentrated hydrochloric acid for 5 minutes. The factory also decided that the author's inference was correct.

After confirming that the nickel plating solution is contaminated by zinc, the following zinc removal process is drawn up, and satisfactory results are obtained by careful treatment . The specific method is:

(1) Add dilute sodium hydroxide solution under continuous stirring to make the pH value of the nickel plating solution reach 6.2, and then continue to adjust the pH value to 6.3 with dilute calcium carbonate solution;

(2) Warm the solution to 70°C and keep stirring at this temperature for 2h;

(3) Filter after standing for 4 hours;

(4) Adjust the pH value to the normal range;

(5) The cathode current density of 0.2A/dm 2 was energized for 2 days and nights.

通过上述的除锌工艺后溶液恢复正常。对余下的这批工件,笔者帮助制定了如下的电镀工艺流程。

A.盐酸强腐蚀至管内没有明显的气泡逸出为止;

B.流动水冲洗;

C.碱液中和;

D.流动水冲洗;

E.压缩空气吹干;

F.磨光、抛光;

G.化学去油;

H.石灰水洗刷;

I.流动水冲洗揩擦;

J.装挂具;

K.电解去油;

L.按一步法光亮镀铬工艺各工序进行。

按照上述工艺镀完本批工件,未发现过任何质量问题。

4、点焊件镀镍后夹缝处周围产生棕褐色铁锈

某次发现,点焊件镀镍后夹缝处周围产生棕褐色铁锈。接缝处周围的铁锈不可能是镀镍时产生的。经检验基材,此处也并未见有锈,镀前也经过酸洗,有的还经过刷洗。那么这些部位的铁锈是怎样形成的呢?

经追踪工艺过程,发现问题出在电解除油工序。原来该厂电解除油的直流电源线路上未装双向闸刀开关,只采用单一的阳极除油步骤。单一的阳极除油不但除油效果差,而且会产生上述的质量问题。起因是:当经过酸洗的工件下槽直接接通阳极时,由于狭缝处难以洗净的残留酸液在阳极电解过程中逐渐向外流出,该处周围的碱液被中和,氢氧根离子浓度降。且酸洗用的是盐酸,氯根作用,推动了铁质基材参与反应,于是产生了大量的锈蚀产物——氧化铁,覆盖在该区域的周围,影响了该处镍离子的还原沉积。

为防止上述现象的产生,采取了下列措施:

(1)工件酸洗后加强清洗(有条件者采用热水清洗更好);

(2)工件在电解除油之前先在化学除油槽中浸泡,以便把狭缝中的残留酸液中和掉。

采用上述措施之后铁锈现象再未发生过。

5、不锈钢闪镀镍溶液被铜离子污染

某乡办电镀厂有一个专做不锈钢镀镍的小组,采用闪镀镍作为预处理工艺,以提高镀层与基体的结合力,投产半年多来效果一直很好,但某一时期发现镍层起泡并且越来越严重,以致无法进行正常生产。笔者应邀前去帮助解决问题。

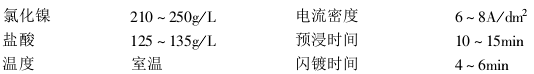

据厂方介绍闪镀镍的配方和工作条件如下:

从闪镀镍的工艺配方和工作条件来看是符合闪镀工艺要求的;查阅近期的分析记录,氯化镍和盐酸的浓度也都在配方范围之内。后来进一步观察,掉皮镍层的剥落面有玫瑰红色,当揭开闪镀槽槽盖见到镍板挂钩和铜梗表面覆有绿色氯化铜,取出镍阳极板发现表面全都覆有一层铜色,这显然是闪镀镍溶液被铜所污染,究其原因有两点:

一是平时(工作时更甚)槽液散发出氯化氢气体直接侵蚀极梗与阳极板挂钩的表面,氯化氢与铜发生反应生成氯化铜,此氯化铜疏松,一碰即掉。由此造成槽液被污染;

二是闪镀之前工件需要在闪镀液中预浸 10-15min,由于在氯化物溶液中捆扎工作的铜丝受到腐蚀。

经实验,一根光亮的铜丝在闪镀镍溶液中浸15min后取出,其表面颜色加深,失去原有光泽;在该溶液中浸渍3h后,紫铜丝直径由0.502mm减少至0.498。闪镀液中铜离子不断积累,达到一定浓度时即会被比铜电位负的金属所置换。在此疏松的置换铜上沉积镍层显然是不牢固的。

6、镀镍阳极板钝化引起溶液 56 值下降

镀镍溶液的PH值一般都比较稳定,正常情况下略有上升,某厂某次有一槽溶液的PH值逐渐下降,是什么缘故呢?厂方感到迷惑不解。其实镀镍溶液 56 值变化的因素并不太多,除溶液中硼酸含量不足之外,如无其他外来因素只要检查阴极、阳极的电流效率即可判断,其因果关系如下:阳极电流效率高于阴极电流效率时,溶液的PH会有上升趋势,否则相反。这一槽镀镍溶液的PH值所以下降有可能是阳极遭到钝化,经检查果真阳极溶解有问题,只见镍板表面全被褐色氧化镍所覆盖。

由于镍板遭到钝化,电流效率低下,通电时只能析出氧气,从而引起 PH值的下降和镍离子浓度的降低,在这种情况下还可能引起镀层针孔增加、光亮度降低、溶液的稳定性降低等一系列质量问题的发生。

7、光亮镀镍层表面出现蓝白色雾膜

某厂前来咨询:光亮镀镍层表面出现蓝白色雾膜,是什么原因?

笔者原认为亮镍层表面产生蓝白色雾膜有可能与镀镍溶液中十二烷基硫酸钠加得过多,或是加法不当,或是光亮剂失调,或是镍离子含量过高、过低,或是PH值控制不当等因素有关。可是,在现场所见到的,则是锻件从镀镍槽取出时的镍层透亮,质量良好,只在晾干后,镍层表面便模糊不清,好似玻璃上罩上呵一层气。这是怎么一回事呢?后来发现,该厂院子很小,却在晾晒工件的不远处有一酸洗棚,只见工人在清洗铜件,黄烟弥漫。毫无疑问,这亮镍层表面的雾膜是受酸雾的侵袭所致。

8、新配制的镀液镀出镍层发白、发雾

某厂配制一槽光亮镀镍溶液,自配成近一个星期以来,几次试镀结果都是镍层发白、发雾,问题迟迟得不到解决。

据现场情况分析,除了光亮剂因素之外(因另外两只镀镍槽用的也是这种光亮剂,且效果都挺好),最大可能是硫酸镍或硼酸的含量不足,再有可能是十二烷基硫酸钠的加法不当。当时查看了该厂施行的工艺资料:亮镍溶液中硫酸镍 350g/L,硼酸35g/L,至于十二烷基硫酸钠的加法工艺中也有详细交待,经与溶液配制者核实也合乎工艺要求。后来在进一步询问中得知,溶液配制时中途曾停过电,停电后溶解硼酸的水无法加温,最后只好把未曾溶完全的硼酸直接加到镀槽,让其自然溶解,结果出现上述现象。

由此可见,镀出亮镍层发白、发雾完全由硼酸未能全部溶解有关。硼酸溶解度低,在配制过程中一定要用沸水溶解,而且溶完后还应加到工作温度的槽液中,否则当时还可能因温度过低和局部处浓度过大而结晶析出。

9、由于操作错误引起镍层发花、发雾

某次常规性的检查中发现,一批板状的镀光亮镍工件中,不少是板的两面光亮度差易明显,甚者,有发花、发白现象,明显形成阴阳面。起初认为有可能是亮镍槽中部分阳极板导电不良,或镍阳极板过短等造成的,于是对亮镍槽进行逐一检查,但均未发现有这类问题。再仔细观察工人的操作,才明白了原委。原来他们没有按照镀亮镍工艺中的有关规定去做,如“镀件出槽时应先关闭电源”等操作要点。而是用了错误的出槽方法,本意是想提高亮镍槽的利用率或提高生产效率,岂料却是违背了规律的。

10、镀镍后未能立即镀铬引起镀铬层发花、发雾

某厂有三只1.5m长的亮镍槽,靠一只12.m长的镀铬槽来完成套铬任务,由于设备数量上配备不合理,镀铬槽由于满足不了镀铬件数量上的要求而积压,不得不临时浸泡在水中待镀,但仍避免不了遭到氧化,给铬的正常沉积带来困难,镀出铬层常发现发雾、发花。笔者应邀前往解决问题时,见到在镀镍车间的镀镍槽旁清洗槽中已挂满等待镀铬的镀镍件。

镀完镍后不能当即镀铬的工件浸泡在水中虽比暴露在空气中好些,但较长时间浸泡在不洁净的水中同样会促使其氧化。同样会给铬的沉积带来困难,问题出在镀镍和镀铬工序之间是毫无疑问的,镀镍和镀铬溶液本身不存在问题,否则开始几槽镀出的铬层为何不存在质量问题呢。

According to生产任务要求,建议厂方增加一只镀铬槽,使镀完镍后的工件能及时套铬,今已改为两只套铬槽,铬层上发花、发雾问题也得到有效解决。

11、光亮镀镍溶液中有关成分的变动与镀层质量的关系

当亮镍溶液中有关成分偏离工艺配方范围时,镀出亮镍层即会出现不同症状的质量问题,尤其是下列几种成分的含量有变化时,即会明显地影响镍层质量,主要是呈现雾状或发花。

12、溶液表面漂有油花对镀层质量的影响

当溶液维护不当或工件预处理不有效时,孔眼部位和狭缝部位的污物、抛光亮膏等即会在电镀时逐渐分离出来,溶液表面往往由此而出现油花,有时虽然只有不连续的薄薄一层,但也足可导致镀出镀层发花、结合力降低等质量问题的发生。

13、电流密度过大引起镍层发雾

There is a bright nickel tank in an electroplating factory, which is usually used to plate serpentine hoses on desk lamps, and each tube is plated. According to this quantity and the specified solution temperature and current density, the quality of the bright nickel layer has always been good. There are One day, the customer sent a batch of urgent items, requiring bright nickel plating immediately. The urgent items occupied about a quarter of the plating tank. After 10 minutes of plating, the workpieces were plated and taken away due to the urgent need of the customer, but the current was not adjusted at this time. , As a result, the nickel layer on the surface of the serpentine tube in this groove all appeared white mist. It can be seen that the reason is all due to the excessive current density, because the bright nickel layer plated from the next groove is still transparent.

If the current density is too small, a satisfactory transparent and bright nickel layer cannot be obtained. This situation often manifests as: the upper and lower workpieces in a series of plated parts are often relatively bright, while the brightness of the middle workpieces is poor (this is because the current density of the middle parts of a series of workpieces is always smaller.

14. The anode area is too small to cause fogging of the nickel layer

There is a %,((- bright nickel tank in a township electroplating factory. Eight electrolytic nickel plates are hung on the front and rear rows of anode stems. Because the electrolytic nickel plates are thin and the nickel plates are at the junction of the liquid surface The dissolution is fast, and seven of the sixteen nickel plates are disconnected from the junction of the liquid surface soon after use, and because the whole nickel plate is wrapped with cloth (to prevent the sludge dissolved on the anode plate from falling into the tank liquid is polluted), so the liquid surface still looks like the whole nickel plate is hanging, and it is difficult to detect without paying attention, but in fact, seven nickel plates are fake, but the nickel plate exposed on the liquid surface is connected , Hanging on the anode rod, it does not play its due role, which causes fog on the negative and positive sides of the coating, or on both sides.