1. Inspection principle

The viscosity of ink can be measured with the help of various specialized instruments. Relatively thick ink can be measured by cone-plate viscometer, drop-rod viscometer, parallel-plate viscometer, etc. Relatively thinner ink can be measured by rotary viscometer, small hole viscometer, etc. These instruments have an established set of methods of use. According to the standard QB5474-83 issued by the Ministry of Light Industry, this section introduces the inspection method of the Amyra Rotational Viscometer.

2. Instruments and materials

(1) Emira Rotational Viscometer

(2) Super Thermostat

3. Inspection method

(1) Before measurement, check whether the liquid pool of the instrument is clean, and calibrate the zero point.

(2) Slowly inject the sample into the liquid pool. Be careful not to be too full or too shallow. Turn on the super thermostat and keep it warm at 25°C.

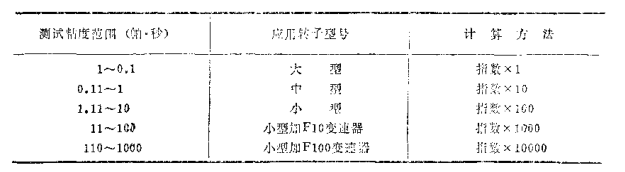

(3) Put a suitable rotary hammer according to the viscosity of the sample and make it rotate.

(4) After 15 minutes of heat-preservation operation, record the indicated data when the reading pointer on the instrument remains at a fixed point for one week, turn off the instrument and return the pointer to zero, then turn on the instrument in the same way, and record the indicated value after the pointer is stable. Data, check whether the two data are the same, the same is correct, and convert.

4. Schedule

5. Precautions

(1) The relationship between viscosity and temperature is very sensitive, and a small change in temperature can cause a large change in viscosity coefficient.

(2) During the measurement, the zero point needs to be calibrated each time.