The viscosity of gravure ink is the first thing to pay attention to in design and use. Of course, it is closely related to fluidity. Whether the viscosity is appropriate is the key to ensure good ink transfer performance and excellent quality.

The viscosity of gravure ink is the first thing to pay attention to in design and use. Of course, it is closely related to fluidity. Whether the viscosity is appropriate is the key to ensure good ink transfer performance and excellent quality.

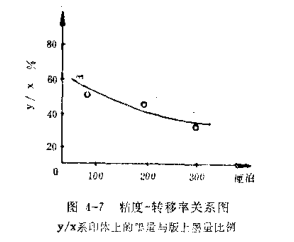

The condition of the viscosity determines the transfer rate of the ink.

It can be seen that the higher the viscosity, the lower the transfer rate. Of course, the transfer rate has nothing to do with the type of resin, ink adhesion, printing speed, printing pressure, printing material condition, and even temperature, humidity, plate depth, etc., but the decisive factor is viscosity.

The factor that affects the viscosity is the solution viscosity of the resin, that is, the smaller the viscosity of the solution of a certain amount of resin and solvent, the lower the viscosity of the ink, and vice versa. The matching between the pigment and the linking material, that is, the properties of the pigment and the coagulation reaction under the linking material, the smaller the viscosity of the system, and vice versa. Miscibility and compatibility of solvents and dispersions. The solvent can dilute the dispersion in any proportion. If the viscosity decreases regularly, the reaction viscosity will be small, and vice versa.

The most satisfying viscosity should be the absolute viscosity measured by a Rotational Viscometer, the number of centipoise is relatively large, while the No. 4 cup measures the conditional viscosity, and the number of seconds is very small, so that the former reflects the relationship between molecules and molecules in the ink. The kinetic friction between the molecules, that is, the attraction between molecules has a certain force, can withstand the mechanical action of printing, and maintain the internal continuous phase from the surface; the conditional viscosity reflects the degree of viscosity and fluidity of the ink dispersion.

Due to the discomfort of viscosity, the problems caused are as follows:

The viscosity of the ink is too small, resulting in low production efficiency. During storage, the gravity of the pigment-resin system causes premature fluid accumulation. Printing with this ink may cause pinholes in the printed product, large areas, and small holes. It is flat and not smooth, and it will make the printed matter weak and appear halo. When printing smooth printed matter, the adhesion is reduced, and when printing paper, there are phenomena such as chalking and dusting.

The viscosity of the ink is too high, resulting in the inability to flow out smoothly from the closed equipment during production. When printing with this kind of ink, it will cause printing failures such as scratches, slightly cross-colored, lake plate, and "love".

Therefore, when designing and making gravure ink, it is self-evident to pay attention to the problem of the degree of research period. Under the existing conditions, it is necessary to control the original viscosity (that is, the viscosity of the original ink) at 0.05~0.25 Pa·s/25°C (measured by Rotational Viscometer), and 25~130 seconds/25°C (measured by No. 4 cup). But at the same time, we should pay attention to the problem of "use viscosity". For example, when the polyamide type ink uses xylene, isolide alcohol, and butanol as a mixed solvent, when the original viscosity is 50~70 seconds/25'c, The black and white base can be prepared with 5~15% of the solvent to make it reach the "use viscosity" of 17~20 seconds/25°C; the red, yellow, blue, green and other colored inks can be prepared with 10~20% of the solvent to make it Reach 18~30 seconds" use viscosity.

For cellulose-based functional inks, alcohol and butyl acetate are used as mixed solvents. When the original viscosity is 30-70 seconds/25°C, 10-15% of the solvent can be prepared for color and white inks to make them reach 15~20 seconds/25°C "use viscosity", red, yellow, blue, green ink, can brew 15~20°C solvent to make it reach 20~30 seconds/25°C "use viscosity", benzene type ink (Ink for printing paper) 15~25% solvent can be added, and the "use viscosity" is in the range of 16~20 seconds. Of course, the original viscosity is already in the range of 20~30 seconds/25°C. It is better not to dilute it again, the effect will be better better.

In short, the "use viscosity" of gravure ink is better controlled in the range of 18~30 seconds/25°C.