Photogravure ink is a volatile drying type. The so-called volatilization is the process in which the energy of liquid molecules reaches the level of breaking away from the attractive force between liquid molecules, so that the liquid molecules escape into the air. Volatile drying is to use this characteristic of the liquid to make the solvent in the wet ink escape, and the ink film changes from liquid to solidified and dry.

Once the gravure ink is printed, the solvent in the ink film layer is required to escape from the system in an instant, so that the pattern of the audio printing product can be dried before the next process can be carried out. Dryness (referred to as dryness) is an important feature of the usability and economy of gravure ink. The drying speed of gravure ink mainly depends on the properties of the solvent. Drying has a decisive influence on the tone of the printing, the accumulation after printing, and the smell of the printed matter. When drying too fast, the thin ink remaining in the concave part of the printing plate after scraping test, the solvent volatilizes excessively and the viscosity rises in a short time after reaching the substrate, so the ink loses its transferability, resulting in insufficient ink in the highlight part and ink in the dark part. Bad, and even cause paste. At the same time, peeling will occur in the process of overlay printing, resulting in poor follow-up; if it is too slow, although the transferability will not cause problems, the post-process cannot be carried out, and overprinting is also difficult.

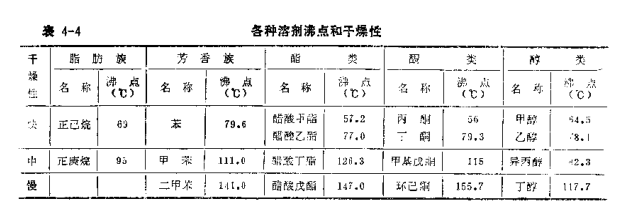

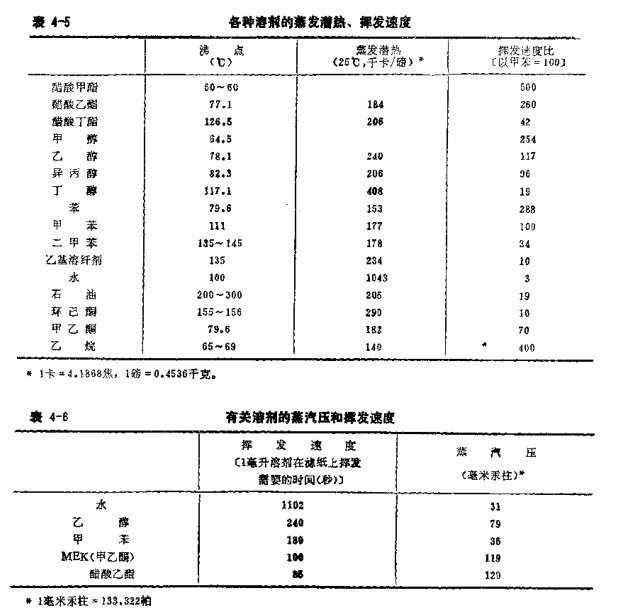

Due to the residual solvent, the ink film is damaged during the transmission of the ink film due to the formation of sticky dirt; in the case of roll printing, the reverse printing phenomenon occurs. These failures are mainly caused by the unsuitable solvent volatilization speed. Of course, improper selection of resin, low softening point of resin, poor removal of resin solvent, poor release of pigment to solvent, excessive high boiling point solvent softening the ink film, etc. are also reasons that cannot be ignored, but it is still a solvent problem. Table 4-4, Table 4-5 and Table 4-8 list some characteristics of the solvent.

As far as a single solvent is concerned, the lower the boiling point, the faster the volatilization speed. But there are exceptions, such as ethyl acetate and ethanol have similar boiling points, but the volatilization rate of vinyl acetate is almost twice that of ethanol. The boiling point of water is not high, but the volatilization speed is very slow. Generally, solvents with medium boiling point, low boiling point and high boiling point are used in combination to meet the dryness requirements of the ink. The volatilization rate of the mixed solvent is restricted by the two solvent molecules, not the arithmetic mean of their volatilization rates.

When mixing ink, the volatilization rate ratio of the mixed solvent is 69~100 (toluene is 100). First select the resin, and then select the solvent, which is an important principle for configuring gravure ink. It is also one of the principles that the dissolution parameters of the breath and solvent are similar to the unit dissolution parameters of the dissolved substance, and that it is easy to dissolve.

When the solvents are mixed, among alcohols, ethanol and benzene have poor mutual solubility, and the mutual solubility between alcohol and benzene is generally in the range of 1:10. Among esters, ethyl acetate and benzene have poor miscibility, generally between ester and benzene at a ratio of 1:10 to 7:10. Other commonly used solvents are miscible.

The larger the saturated vapor pressure, the faster the volatilization, and the smaller the latent heat of evaporation, the faster the volatilization. At a certain temperature, the shorter the volatilization time of the same volume of liquid, the faster the volatilization.