本文介绍基于可编程控制器的多台虹吸式离心机自动控制系统。着重介绍系统的组成、各个部分的功能,以及控制流程等。随着可编程控制器功能模块的发展,扩展了它在工业生产过程自动化中的应用。

1引言

虹吸式离心机是一种特殊结构的离心机,它是在刮刀离心机的转鼓上增加了转动虹吸装置,从而具有普通刮刀离心机没有的优势,即提高了过滤推动力及过滤效率,增加了生产能力,延长了有效周期[1]。然而,虹吸式离心机优势的正常发挥是以准确操作控制离心机为前提条件。虹吸式离心机是连续运转、循环工作的,各工序间严格以时间或条件为控制According to,每个阀门的开、关控制及虹吸管的协调工作不能在一般的人工操作条件下达到要求。

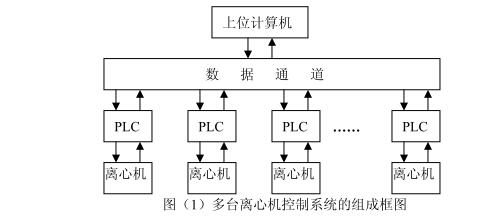

可编程控制器(PLC)是常用于工业现场的计算机控制装备[2],随着其扩展功能和通信能力的增强,越来越多的应用于复杂的分布式计算机控制系统。本文利用可编程控制器的通信功能,来控制多台虹吸式离心机的运行,不仅能够准确分散地控制每一台离心机正常、有效工作,而且能够通过上位机集中采集、显示、修改每一台离心机的运行参数,起到控制及风险分散,显示和操作集中的目的。

2系统的组成

(一)PLC的功能模块

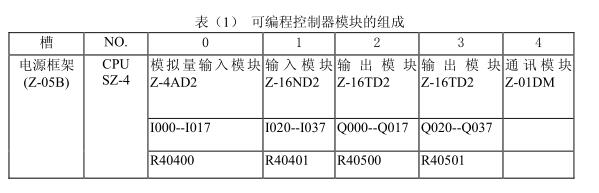

PLC作为控制系统的基本控制器。PLC向下采集信号以及控制工业现场的离心机。一台PLC控制一台虹吸式离心机。包括控制离心机的主电机的启停、各个电磁阀的动作、虹吸管的进退、显示和报警的控制等。PLC在每一个采样周期采集模拟信号,包括主电机的电流信号、主机前后轴承的温度、振动信号。PLC向上通过数据通道传输现场信号,并接收上位机来的信号。PLC作为整个控制系统的主体,它的性能及可靠性起着关键的作用。我们选择光洋电子公司的S系列可编程控制器。它的模块组成如表(1)所示。

表(1)可编程控制器模块的组成

The CPU is SZ-4, which can install 128 input and output points. The average processing speed of instructions is 1-2.5µs, and there are 2 general-purpose communication ports. Z-4AD2 is a 4-channel voltage-type analog input module, the input DC0-5v resolution is 12 bits, and it mainly collects 4 analog signals of current, temperature and vibration. Z-16ND2 is a 16-point DC24v input module, which inputs switching signals such as start-stop buttons and limit switches. The two output modules are Z-16TD2, which are 16-point open-collector outputs, and output the contactors that control the start and stop of the motor, the solenoid valves, indicator lights and alarm switch signals required for the operation of the centrifuge. Z-01DM is a communication module, which is convenient for signal transmission with the host computer. Z-05B is a power frame that can hold 5 input and output modules, the rated power supply is AC100-200v50/60HZ, and the output current is 2.6A. By calculating the total value of power consumption of all modules on the frame, it does not exceed the power capacity provided by the power frame and can be used safely [3].

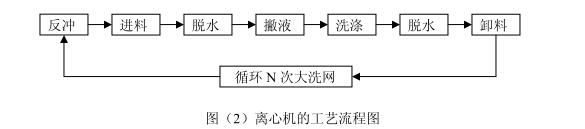

(2) Process flow of the centrifuge

The centrifuge is mainly composed of a screw assembly, a door cover assembly, a drum assembly, a frame shell assembly, a siphon assembly, a transmission device , a hydraulic system and an electrical control system. The process flow diagram of the centrifuge is shown in Figure (2).

Each operation of each cycle of the centrifuge is automatically completed under the control of the electro-hydraulic system, and manual operation can be used during the commissioning stage of the machine.

(3) Communication system

The host communication is carried out on the CCM network through the data communication module Z-01DM. The CCM protocol enables the communication host to

Hold the communication initiative, the slave can only respond to its calls. The communication station number, transmission mode, and parity check mode are set by system parameters. When connecting, use the converter D-01CV to convert the RS-232C cable connected to the upper computer and the RS-422 cable connected to the PLC communication module.

(4) Host computer

The upper computer communicates or collects the centrifuge operation information to the basic controller PLC, and the upper computer maintains and manages the PLC. The upper computer is realized by industrial computer, and the graphic monitoring and man-machine interface are realized by configuration software.

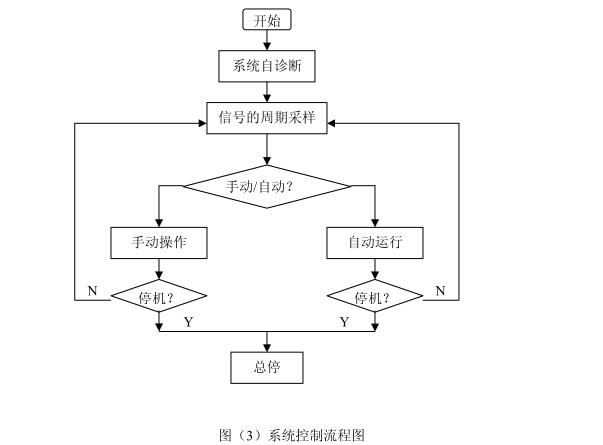

3 control flow chart

PLC control flow diagram shown in Figure (3).

After the PLC is powered on, the first system self-inspection is performed, including the inspection of the CPU module, the inspection of the operating status, the inspection of the battery system, the inspection of the I/O module, the inspection of the communication function, etc. The system normally performs periodic sampling of the analog signal, and outputs an alarm if it exceeds the upper limit. The system can be operated manually or automatically, and the automatic operation follows the process flow of the centrifuge and is executed in sequence, with time or conditions as the beginning or end of each process.

4 Conclusion

Due to the development of programmable controllers in analog signal processing, operation instructions, control rules, communication functions, etc., its application field in industrial strong current field control has been broadened. As a kind of separation equipment with unique structure, siphon centrifuge considers its process characteristics and operation control requirements. Programmable controller is very suitable as its control equipment to give full play to the effective advantages of siphon centrifuge.