Defelsko PosiTector UTG ultrasonic wall Thickness Gauge is an ultrasonic Thickness Gauge for measuring the wall thickness of materials. According to whether the probe has paint penetration ability, it is divided into UTG C and UTG M probes, which are single-echo and multi-echo probes. The following is a comparison of the two probes in terms of appearance, size, measurement function principle, and parameters.

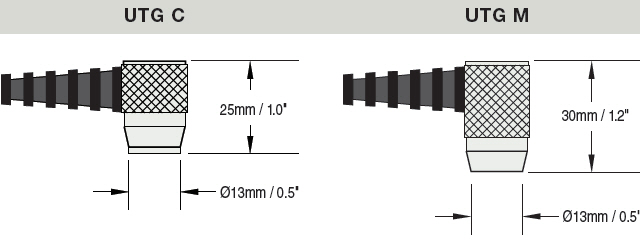

Differences in Probe Appearance

UTG C UTG M

Probe Size Comparison

Probe working principle comparison

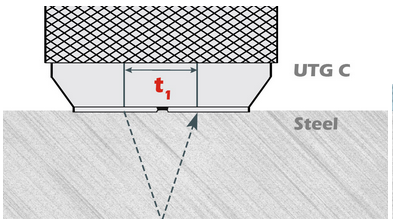

The PosiTector UTG probe works by transmitting an ultrasonic pulse into the material under test. This pulse travels through the material to the other side. When it encounters an interface, such as air (back wall) or another material, the pulse returns to the probe. The time it takes for the pulse to travel from the probe to return to the probe is measured by the gage and is denoted below as t1 and t2.

single echo

The PosiTector UTG C-probe is a dual pair transducer with automatic V-path compensation. Thickness is determined by measuring t1 (uncoated) or t2 (coated), divided by 2 and multiplied by the sound velocity of the material (steel). See Figure 1 below

t2>t1

For uncoated materials t1 is a direct measurement of the material thickness. When the surface of the material is coated, the propagation time increases to t2 referred to in the figure above.

Coatings like paint have a slower sound velocity than metals. Therefore the single echo technique will produce thickness results that are greater than the actual combined coating + metal thickness. This thickness value would include a significantly higher and unknown value for the paint thickness. Therefore, it is difficult to obtain an accurate material thickness value by measuring the paint thickness and then subtracting the paint thickness from the result of the single echo measurement.

multiple echoes

PosiTector UTG M transducers determine thickness values by measuring the time between at least 3 consecutive posterior wall echoes.

t1=t2=t3

As shown above, the multi-echo mode only measures the time between echoes. All times between echoes are the same regardless of whether the material is coated or not. In multi-echo mode, the Thickness Gauge measures the time t1+t2+t3, divides it by 6, and multiplies it by the sound velocity of the material to get the final thickness. The final thickness calculated by the instrument is an accurate measurement of steel thickness only, ignoring coating thickness.

The speed of sound is expressed in inches per microsecond or meters per second. Different materials are different. For example, sound waves travel faster in steel (~0.233 in/µs) than in plastic (~0.086 in/µs).

Comparison of technical parameters

| type | corrosion | for echo |

| Probe model | UTG C | UTG M |

| Probe type | 5 MHz Dual Even | 5 MHz contact |

| Penetration ability (multi-echo) | none | have |

| Measuring range - single echo | 1.00~125.00mm | 2.50~125.00 mm |

| Measuring range - multi-echo | none | 2.50~60.00mm |

| resolution | 0.01 mm | 0.01 mm |

| precision | ±0.03 mm | ±0.03 mm |

For detailed information about ultrasonic wall Thickness Gauge , please enter: http://www.nbchao.com/p/3349/