1. Purpose

Establish a standard procedure for the analysis of raw materials, semi-finished products (intermediates) and finished products in order to obtain reliable data on quality.

2. Scope of application

QA, QC

3. Responsibility

QA inspectors and QC analysts should strictly follow the operating procedures, and QC supervisors and QA supervisors are responsible for supervising the implementation of this procedure.

4. Definition

HPLCHigh Performance Liquid Chromatography,Effective liquid chromatography.

GCGas Chromatography,Gas Chromatograph.

UVUltraviolet,UV Spectrophotometer ).

VISViscometer,Viscometer.

QUARTSQuality Assurance Reporting System,Quality assurance reporting system.

LIMSLabInformationmanagementsystem Laboratory information management system

5. Safety Precautions

none

6. Procedures:

6.1. Sampling

6.1.1. QA personnel prepare sampling containers according to the inspection form, and take samples of raw materials, semi-finished products (intermediates) and finished products according to regulations. Fill out the sampling form after sampling. Take two samples from each batch (the volume of each sample should be at least twice the assay volume), and one of the bottles is currently used for assay and labeled in black and white (see Appendix 1). Another bottle is used for reserved samples, and it is pasted with a white paper and red letter label (see Appendix 2) and handed over to the QC analyst for storage in the sample retention room. The product name, specification, batch number, sampler's name, and date should be filled on the label. According to GMP requirements, each batch of products and raw and auxiliary materials used in product production must have samples, and the reserved samples shall be classified and stored in a special location in the sample storage room by the responsible personnel, and the appearance inspection shall be carried out regularly.

6.1.2. When the QC laboratory personnel receive the inspection form and samples, they first check whether the items are filled in completely, whether the purpose of the inspection is clear, whether the sample is consistent with the inspection form, whether the raw and auxiliary materials are sent for inspection with the factory qualification report, etc. After inspection, sign the delivery form for inspection, and record it on the sample receipt record (see Appendix 3), and register it on the QUARTS or LIMS system at the same time.

6.1.3. Sampling should be carried out according to the sampling rules. After sampling, directly record in the sampling record book (including barrel number, visual inspection status).

6.2. Assays

6.2.1. Select the test method according to the serial number or product name of the test variety, and prepare the required instruments, test solution, standard solution and other necessities for the test. If the test period is specified, the test shall be completed within the specified time limit.

6.2.2. Operate in strict accordance with the prescribed test standards, and do not change the test method during operation. If there is a problem with the assay method, notify the QC supervisor so that the problem can be resolved, but no changes can be made to the assay method without the permission of the QC supervisor.

6.2.3. When using the instrument (such as HPLC or UV Spectrophotometer ) for a long time, you can put a "running" mark on the instrument. After the instrument is used, take it off in time and fill in the use record . The instrument should be checked and calibrated according to the corresponding SOP. The instrument should only be used when it is functioning properly. If the instrument is abnormal, the user should promptly notify the instrument management personnel to put the "fault" mark on the instrument until the problem is solved. An instrument without any mark means it is not powered on.

6.2.4. Except for content, which needs to be tested twice in parallel, one test is usually sufficient for other test items. If the parallel test data exceeds the error requirements specified in the method (but within the acceptance limit), the QC supervisor should be notified to find out the reason. Under normal circumstances, another test is required (that is, another test is required when the cause of the error cannot be judged).

6.2.5. During the experiment, the original records should be made timely and accurately on the prescribed original test record paper.

After the test is completed, the used instrument should be cleaned up in time for the next laboratory technician to use. All glassware should be rinsed out of the experimental samples after use, so that the samples are not difficult to clean after drying, and then sent to the cleaning room for cleaning. The handling and testing of volatile substances should be carried out in a fume hood. Appropriate methods should be used to dispose of volatile and toxic substances.

6.2.6. After the sample testing is completed, the analyst should print the report in time, and the report should be reviewed by the QC supervisor. If the test results meet the requirements, the QC supervisor will sign the test report for approval. If the requirements are not met, take corresponding measures referring to the relevant regulations in SOPQCT006 "Regulations on Re-inspection of Raw Materials and Packaging Materials Stored in the Warehouse". The analyst is responsible for the quality of the test and the errors in the test, and the reviewer is also responsible for the errors in the calculation.

Assays should be completed in a timely manner (eg, on plain tablets to be coated and finished products to be packaged) to avoid delays in production.

6.2.7. Completion of sample testing includes timely, complete and accurate analysis of samples and correct completion of test reports.

6.3. Laboratory report

The whole process of sample testing should be filled with original records, and the records should be accurate, complete and timely. The specific requirements are:

6.3.1. The records should be written clearly and neatly. In case of data or writing mistakes, no alterations are allowed, and no correction fluid is allowed. "____" should be drawn on the wrong place, and the corrected data should be filled in, and then the name and date should be signed for future reference. If necessary, the reason for the revision should be indicated.

6.3.2. The original record should include the name and type of the sample (batch number), the appearance of the sample, the weight of the sample, and if necessary, indicate the supplier’s test report for reference, and the content calculation formula of the intermediate and the finished product; if using The reference substance should indicate its weight, purity, test result/phenomenon, conclusion and signature of the analyst, and the signature of the reviewer.

The original test records are classified and numbered according to the types of test items, and the numbering principle is: ARXX (XX is the sequence number).

AR01: General ItemsAR02: HPLC/GC

AR03: UV/VISAR04: Dissolution Test

AR05: Preparation of chemical test solution and indicator solution

6.3.3. The test records should include the analysis chart and other records, which should be attached to the test report, and the product name, batch number, date, etc. should be indicated on the chart.

6.3.4. Accuracy of various data

The significant figures of the sample weighing should be consistent with the accuracy of the balance used;

The ml of standard solution consumed should be read as 0.01ml.

In the process of data processing, the rule of "rounding off to 50 percent" is adopted for the rounding off of the numbers after the effective digits, see GB8170-87 "Numerical Rounding Rules".

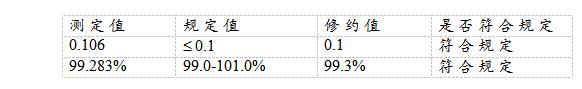

The number of significant digits in the final reported test result should be consistent with the method requirements. In the process of calculation, the effective digits can be properly reserved, and then rounded to the specified effective digits according to the rounding rules of effective digits, and then the rounded data is compared with the limit value specified in the standard to determine the actual index or Whether the parameters meet the standard requirements. For example:

6.3.5. Requirements for relative error of preparation content analysis

HPLC method: 1.5%

UV method: 1%

Titration method: 0.5%

Bioassay: 2.5%

The content of raw materials shall not exceed 50% of the relative deviation of the above method.

6.3.6. Laboratory report

The laboratory technician should issue a report and sign it in time after completing the experiment, and submit it to the laboratory supervisor after review and signature by the reviewer. The laboratory supervisor will judge, approve and sign according to the experimental results. A manual report should also be issued for the finished product (see Appendix 4). Among them, the method is based on the source and number. The batch size is the actual storage quantity after deducting the amount of sampling and reserved samples, which can be consulted in the BPCS system. If the finished product inspected in the conclusion item is a commissioned product, it should be indicated that it is only responsible for the quality department of a certain company.

6.4. Distribution and archiving of test reports

6.4.1. The original records and reports of raw materials, intermediates and finished products are archived by the laboratory. After copying the report, submit it to QA, and QA will distribute it to relevant departments according to specific requirements.

6.4.2. The reports of intermediate products and finished products shall be kept for at least one year after the expiry date of the finished products, and the reports of raw and auxiliary materials shall be kept for at least one year after the expiry date of the last batch of finished products made with the raw materials.

6.4.3. If it is necessary to take the test form from QC, the person who takes it must register and sign, and write the date of taking it and returning it. If a copy of this report is required, it must be approved by the QC supervisor, and the word "COPY" should be stamped on the copy.

7. Reference

"CHINA Standard Operating Procedures for Drug Inspection"

8. Distribution department

Quality Assurance Department

9. Revision history:

Modify the WORDS report format of the finished product.