Coating hardness refers to the resistance strength of the coating to local surface deformation caused by external force. For thinner coatings, microhardness tests are generally used for hardness determination, and macroscopic hardness tests are required for thicker coatings. For example, the file test is a macroscopic qualitative test, that is, a common file is used to file on the coating, and the hardness is qualitatively expressed by the degree of cutting. Microhardness tests include Brinell, Vickers and Knoop methods. The Brinell microhardness method uses a small steel ball indenter. The hardness of the coating measured by this method is greatly affected by the substrate, so this method is generally not used. The Vickers hardness method uses a square cone indenter, and the indentation is square. The measured hardness value of the coating is less affected by the substrate and the applied load. It can be used as a method to measure the hardness of thick coatings. However, when measuring the hardness of thin coatings, metallographic samples should be prepared first and measured on the cross-section of the coating. If the measurement is carried out on the vertical coating surface, the correct result cannot be obtained generally. The Knoop hardness method uses a pyramidal indenter with a diamond-shaped indentation. It is widely used because of its high sensitivity to the determination of the hardness of thin coatings.

1. Micro hardness measuring instrument

Microhardness can be measured using a microHardness Tester. The measurement principle is to use the diamond indenter attached to the instrument to add a certain load to make an indentation on the surface of the test sample, and then use a reading microscope to measure the size of the indentation, and calculate (or look up the table) to obtain the test sample. The hardness of the surface coating. Due to the different forms of diamond indenters and different calculation formulas, the obtained microhardness values are also different.

2. Microhardness determination method and precautions

(1) Requirements for operating the instrument

Operate strictly according to the instruction manual of the instrument.

(2) Requirements for the appearance and preparation of the measurement sample

In order to minimize the measurement error, the surface of the sample should be flat, smooth and free of oil. When measuring the hardness of the section, it can be prepared as a metallographic sample.

(3) Requirements for measuring the coating thickness of samples

When measuring the hardness on the cross-section, there are certain requirements for the thickness of the coating. According to ISO4516-80, if measured with a Vickers indenter, the thickness of the coating should be sufficient to produce an indentation that meets the following conditions.

① The distance between each corner of the indentation and any side of the coating shall be at least half the length of the diagonal.

②The length of the two diagonal lines should be equal (the error is less than 5%.

③ Both sides of the indentation should be equal (error within 5%).

If the Knoop indenter is used, ISO4516-80 stipulates that the thickness of the soft coating (aluminum, copper or silver) should be at least 40 μm; the thickness of the hard coating (nickel, cobalt, iron and hard precious metals and their alloys) should be at least 25 μm.

When measuring perpendicular to the surface of the coating, ISO4516-80 stipulates that if a Vickers indenter is used, the coating thickness should be greater than or equal to the average length of the indentation diagonal! "( Times. If a Knoop indenter is used, the coating thickness should be at least 1.4 times of the longer diagonal line of the indentation. Satisfactory measurement results can be obtained for thinner coatings only when the hardness of the substrate and the coating are similar.

(4) Selection of load size

Try to choose a large load within the possible range in order to obtain a larger size indentation, thereby reducing the relative error of measurement. To make the measurement error ≤ 5%, the indentation diagonal should be ≥ 16 μm. ISO 4516-80 stipulates that materials with a general hardness value below 300HV , noble metals and their alloys and thin coatings use a load of 0.245N. The hard anodized film on aluminum adopts 0.490N load. Non-precious metal materials with a hardness greater than 300HV use a load of 0.981N.

(5) Requirements for applied load

The load should be applied steadily and slowly, without any vibration and impact. ISO 4516-80 stipulates that the indenter indentation speed is 15~17μm/s, the load is kept for 10~15s during the test, and the measurement temperature is (23±5)℃.

(6) Measure the average value

On the same sample, take at least one measurement at different parts under the same conditions! Take the average value of each measurement as the measurement result.

3. Calculation of hardness value

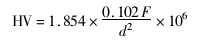

(1) Vickers microhardness is calculated according to the following formula

Among them, HV represents the Vickers microhardness; F represents the load applied to the sample (N); d is the diagonal length of the indentation (μm).

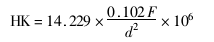

(2) Knoop microhardness calculation formula:

HK means Knoop microhardness; F is the load applied to the sample (N); d is the diagonal length of the indentation (μm)