1. Delayed destruction test

This test is suitable for determining the hydrogen embrittlement of ultra-high strength steel, and it is a standard test method with high sensitivity.

(1) Sample shape and size

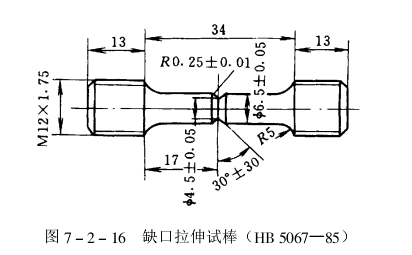

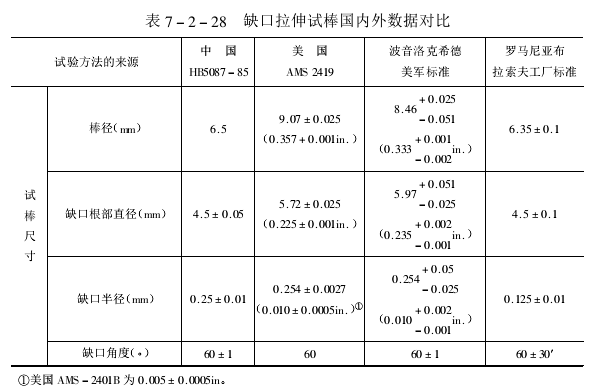

The material to be tested is made into a notched tensile test bar, see Figure 7-2-16) and Table 7-2-28 for the shape and size.

Preparation of sample: The sample should be rough machined after annealing, then heat treated, and finished to the required size (should be

Ensure that the radius of the root of the notch is smooth), and the surface roughness of the sample is Ra0.40~0.80μm. Before electroplating, the stress should be relieved at a temperature lower than the tempering temperature of the sample (below 10~20°C). During electroplating, the thickness of the coating at the notch of the sample is 12-18 μm (12.5 μm is the most suitable), and the hydrogen is removed after plating.

(2) Test method

Put the notched tensile test bar processed and prepared under the specified conditions on a 3-5t Tensile Testing Machine and apply an overload of 75% of the tensile strength of the unplated sample to conduct a delayed failure test. If hydrogen embrittlement occurs in the sample, fracture will occur within a few hours to 100h; If no fracture occurs after 200h, it proves that there is no hydrogen embrittlement, that is, the hydrogen embrittlement performance is qualified.

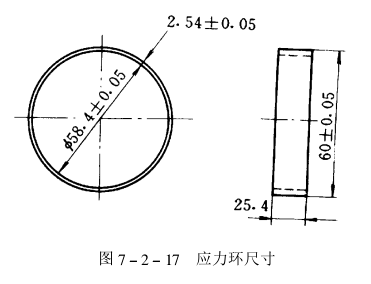

2. Stress ring test

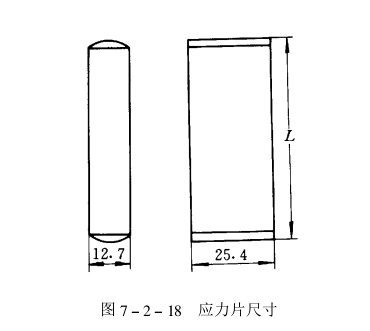

Choose the same material as the part to process three stress rings according to the size shown in Figure 7-2-17, and electroplate them under the same production conditions. After dehydrogenation, clamp the stress rings on the vise to make them oval , the radius of the ellipse can just fit into a stress sheet (see Figure 7-2-18 for dimensions). In Figure 7-2-17, L is (64.1±0.05)mm or (64.1±0.03)mm. At this time, the stress state of the stress ring is similar to the overload of 90% of the ultimate tensile strength. When the stress ring is not broken after 200h of static placement, it indicates that there is no hydrogen embrittlement.

3. Using a hydrogen Tester to test

In the hydrogen embrittlement test, the stress ring and delayed failure test are used for the quality control of the electroplating process. And the hydrogen meter can be used for daily bath maintenance.

Hydrogen measuring instrument is mainly used to measure the amount of hydrogen precipitated during electroplating and the difficulty of dehydrogenation of the coating by using a vacuum degree measuring instrument to evaluate hydrogen embrittlement.

In addition, the extrusion test can be used as a measure of hydrogen embrittlement acceptance for spring washers. The slow bending test can be used to compare the hydrogen embrittlement of the same material treated by different electroplating processes, and it can also be used to compare the hydrogen embrittlement of different materials under the same electroplating process conditions.