在油田部门,使用变频器去控制交流电动机的转速、转向,变得越来越广泛[1 ̄2]。为了实现集中控制,常需要用一台工控机或微机去控制多台变频器。针对这一需要各变频器生产厂家推出了带有RS-485通信接口的变频器,其中西门子公司生产的新一代多功能的Micro-Master440变频器(简称MM440变频器),因其采用高性能的矢量控制技术,提供低速、高转矩输出和良好的动态特性,同时又具备超强的过载能力,而得到了广泛应用。

因此,重点阐述了要实现一台计算机对多台MM440变频器[3]实现矢量控制,应如何设置MM440变频器,以及如何利用VC++的MSComm控件实现对MM440变频器集中控制,从而达到有效控制离心机的转速,满足油田的实际工况。

1系统组成

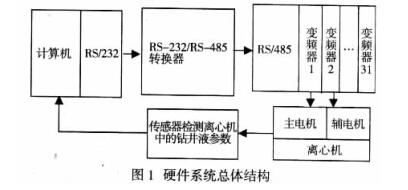

为了满足油田部门的实际工况,采取将计算机、变频器、RS-232/485转换器,有效的结合的方法,来达到有效控制离心机的主

辅电机,从而改变离心机的转速。如图1所示,计算机通过从RS-232串口取电、并能自动识别和控制数据传输方向的RS-232/485转换器,与多个MM440变频器相连(最多达到32台)。为了达到区分各个变频器的目的,每个变频器采用不同的地址码。因此,可以清楚的发现,这套控制系统可以实现计算机对16台离心机的同时控制,方便有效的进行远程计算机控制,发挥离心机很好的功用,满足油田需要,更好的达到固相控制系统的完善。

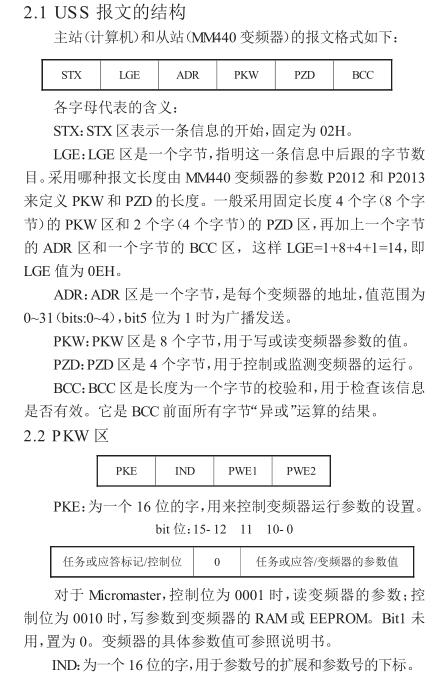

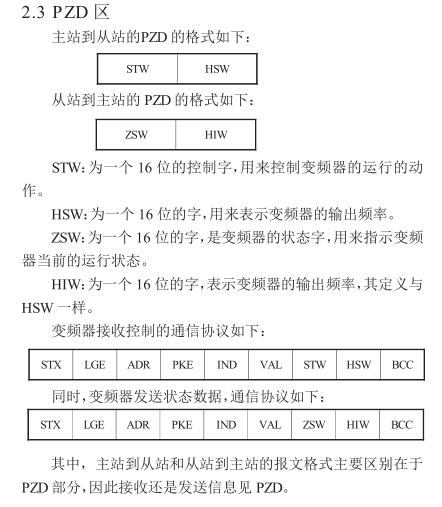

2MM440变频器的串行接口协议(USS)

西门子MM440变频器可采用两种串行接口:RS-232或RS-485。采用RS-232接口时,需另选配件。当采用RS-485接口,波特率为9600bps时,通信距离可达1200m,最高波特率可为115200bps,但此时通信距离大约只有15m。

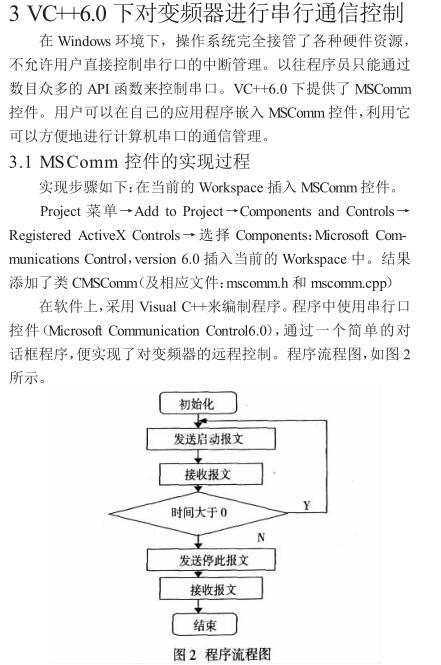

3.2初始化实现过程

在对话框初始化函数OnlnitDialog()中对串行口的一些参数进行初始化的代码。

By programming, the control of the start, run, stop and running time of the frequency converter is realized. Therefore, the direct control of the frequency converter indirectly realizes the operation of the centrifuge, so that we can achieve a reasonable operation of the centrifuge speed through the changes in the drilling fluid in the centrifuge and the performance of the centrifuge, and solve our problems. actual needs.

4 Conclusion

Using the ActiveX control under VC++6.0 and the serial communication function of MMV frequency converter RS485, the task of controlling the frequency converter with a computer under Windows environment is realized, and the running status of each frequency converter can be detected in real time. The whole control system is flexible and convenient, and has great practicability. In the oilfield sector, according to the change of the performance of the drilling fluid in the centrifuge, this closed-loop control system can effectively play the role of the centrifuge, remove harmful solid phases, and recover heavy materials, which has broad application prospects.