One ,use

WG-2A/2B is a special industrial centrifuge, which is widely used in laboratories or workshops in papermaking, printing and dyeing industries, such as: sample preparation for beating degree test, pulp concentration determination and laboratory washing pulp, etc. .

2. Specifications and main technical parameters

1. Dehydrated weight: 100~500g;

2. Dehydration speed: WG-2A: 2800r/min;

WG-2B: 1400r/min/;

3. Dehydration time: 1s~60min;

4. Power supply: AC220V±10%, 50Hz;

5. Dimensions (length×width×height), mm: 420×260×210;

6. Instrument mass: 21kg.

3. Product performance characteristics

It adopts electronic control technology, has a simple appearance, and has a transparent observation window. It has the characteristics of easy operation, high dehydration efficiency, low noise and stable operation, and is equipped with an external anti-shock protection plug to ensure the safety of operators.

4. Use environment and requirements

Laboratory environment: temperature 5 ~ 35 ℃, relative air humidity ≤ 85%, power supply: single-phase three-core socket (with grounding protection).

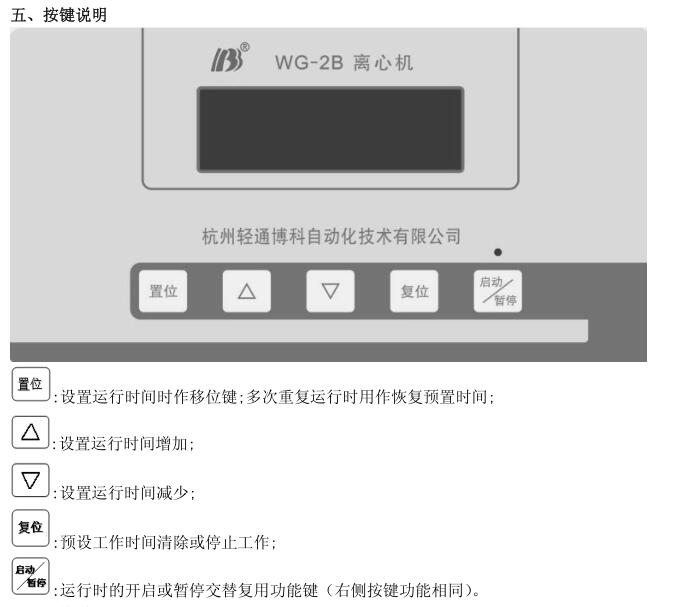

6. Operating Instructions

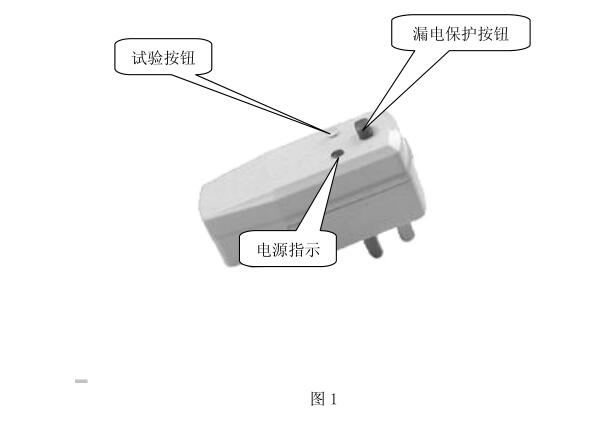

1. Connect the power cord, test the protective effect of the leakage prevention plug (as shown in Figure 1), press the "test button", if the "leakage protection button" pops up, the power indicator light goes out, indicating that the protection action is normal. Press the "leakage protection button" to reset and the centrifuge can operate normally; this test is recommended to be carried out once a month to ensure safety.

2. Place the centrifuge on a flat work surface, and ensure that the 4 legs are in firm contact with the platform.

3. Connect the outlet pipe under the body to the outlet pipe for drainage.

4. Turn on the power switch at the rear of the machine.

5. Open the plexiglass cover, put the items to be dehydrated into the porous drying barrel (try to put them evenly into the bottom of the drying barrel), and cover the protective cover. Press the "Set" button to select the minute and second position when setting the time, press the or button to set the running time (for example: 10:11 is running for 10 minutes and 11 seconds), press the "Start" button to start running, wait until the preset time is up When reached, the drum will stop by itself. If there is an abnormal situation during the working process of the centrifuge, you can press the "pause" button to stop the machine from working. (Note: You can put your hands into the drying barrel only after the drying barrel has completely stopped rotating)

6. During multiple drying operations, if you want the instrument to run at the same time as the last time, directly press the "Set" button or wait for 10 seconds, and then press the "Start" button; if you want to set other working hours, you can First press the "Reset" button, and then follow step 5.

7. Press the "Start" button during the operation to pause, and then press the "Start" button to run for the rest of the set time.

7. Common faults and solutions

1. If the leakage protection test is unsuccessful, first check whether the external power supply is normal. Then unplug the connection plug between the power cord and the body and try again. If the leakage protection plug responds normally at this time, it may be caused by moisture leakage in the body.

2. There is no response when starting up. You can turn off the machine and try again. If it still does not work, you should check whether the leakage protection switch is activated or whether the fuse intact. Open the fuse cover at the power cord interface of the instrument. If the fuse is blown, replace it with the attached fuse tube. Water, damp, and unstable external voltage inside the machine can cause the machine to work abnormally.

3. If it is found that the motor is running normally, but the drainage is not smooth, there may be foreign matter blocking the water outlet, turn off the power, unplug the plug separate the drain pipe from the body, and use a long rod with a diameter of ≤8mm and a length of ≥300mm to clean the drainage interface. dredge.

8. Matters needing attention

1. Do not open the lid or put other items into the rotating drying drum before it completely stops rotating, so as to avoid accidents.

2. If there is a failure when the machine is working, please turn off the power first, take out the items in the drying barrel, and then find out the cause of the failure.

3. Be careful not to splash water into the body during daily use and cleaning, so as not to cause leakage and damage internal electrical appliances.

Nine, maintenance

After each shift/time of using the machine, you can clean the spin-drying barrel with clean water (do not splash water into the machine, and do not use organic solvents and strong alkaline liquids to clean transparent parts), and use a dry cloth to wipe off any water stains on the surface of the machine. Wipe it clean and unplug it to prolong the life of the machine. It is recommended to clean the sink once a week.