traditional laboratory water

In the long river of history, in order to pursue the accuracy of the experimental results, scientists discovered the principle of thermodynamic separation, that is, after the source water is boiled, the water quality after evaporation and condensation is purer and more in line with the experimental standards, so distilled water was invented. For a long time, laboratories have used distilled water for experiments.

Traditional laboratory water is made by distillers, or ion exchange resins are used to obtain purified water, and then pure water, distilled water, or deionized water is used as influent water, and after purification and ultra-purification units, ultra-pure water is produced. , This is the so-called first generation ultrapure water machine. At present, some customers are still using distillers to obtain distilled water, but this method has problems of varying degrees. The safety of the distillers is poor, and there is a risk of dry burning and bursting pipes; the cooling water consumption is large, it is inconvenient to use, and special personnel are required to be on duty; The main thing is that the water obtained by the distiller and the ion exchange device still has disadvantages such as low water quality and unstable water quality, which cannot meet the water demand for increasingly refined scientific research experiments.

Comparison of advantages and disadvantages of the first generation ultrapure water machine:

advantage:

The system flow is simple, the control is convenient, and the machine is compact.

shortcoming:

1 Only produces ultrapure water.

2. A separate device is required to draw distilled water or deionized water to provide water for it; the operation is troublesome.

3 Double purchase cost; high energy consumption and high operating cost.

1950s

Scientists in the United States have discovered the basic theoretical framework of the reverse osmosis method through research. The principle of reverse osmosis was used in laboratory ultra-pure water machines earlier in the United States, and the pure water technology called "pure water revolution" was also promoted in Japan and Taiwan, CHINA earlier. This "pure water revolution" is Traditional laboratory water brings revolutionary convenience. However, this technology did not enter the Chinese mainland market before the early 1990s.

Until 1997, Taiwan, CHINAese companies brought their brand "Aquapro", making "Aquapro" the brand of formed products born earlier in CHINA's "ultra-pure water machine" industry.

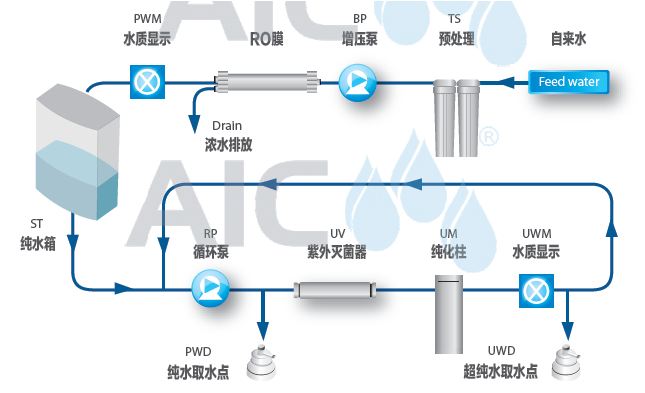

Tap water is used as the input water, and pure water and ultrapure water are produced at the same time. Using pressure buckets or industrial buckets, adopting pipeline connection, and integrating the ultrapure water machine of pretreatment reverse osmosis purification column, this is the second generation of ultrapure water machine.

The second-generation ultra-pure water machine entered the ultra-pure water machine market in the Chinese mainland, making the Chinese water treatment industry change from unshaped production to standard industrial equipment products.

Comparison of advantages and disadvantages of the second generation laboratory ultrapure water machine:

advantage:

1 Use tap water as the input water to produce pure water and ultrapure water.

2 One step in place, easy to operate.

3 There is no need for double purchases, which reduces operating costs and purchase costs.

shortcoming:

1 There are few water quality monitoring points, which cannot be recorded, and data query and traceability cannot be realized.

2 The design of one-stage reverse osmosis is adopted, which is easily affected by the change of raw water quality, and the quality of produced water is unstable; the utilization rate of raw water is only 15%, and the RO membrane wears out quickly, and the cost of water production is high.

3 The failure of the water machine requires professional and technical personnel to come to the site for diagnosis, and the maintenance time is long, which makes the experiment impossible.

4 The traditional hose connection method, the pipeline is complicated, and professional and technical personnel are required to come to replace the consumables.

On January 1, 2013, Aikepu successfully independently developed the world's third-generation laboratory ultra-pure water machine. This is not only a technical innovation, nor a product replacement, but a shocking revolution in the laboratory ultra-pure water industry.

The third generation laboratory ultrapure water machine

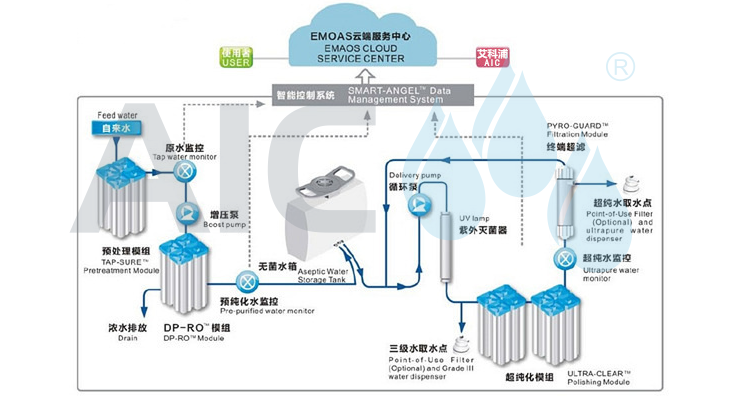

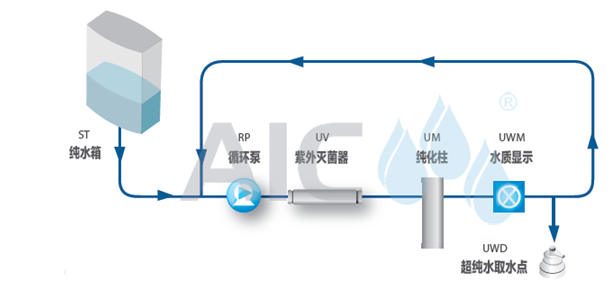

It is a standard that meets the requirements of the CLSI (American Clinical Laboratory Standards Association) standard to verify the ultrapure water used during the experimental operation to ensure that it is suitable for its intended purpose, and to monitor the trend of the water purity specification , an ultrapure water machine that can verify, validate and automatically monitor water purity specifications and trend changes. Its system, overall machine structure, human-machine interface and various module components have far surpassed the second-generation ultrapure water machine.

The advantages of the third-generation laboratory ultrapure water machine:

advantage:

1. The whole system intelligent multi-point monitoring all-in-one machine ensures stable water quality;

2. Intelligent user management, multi-language, multi-user independent pricing;

3. Flexible and simple operation, true color LCD touch screen, graphic man-machine interface;

4. Self-diagnosis of the system, automatic alarm or shutdown of abnormal operation, prolonging the service life of the equipment;

5. Data storage and analysis, the experimental results are well documented;

6. Patented DP-RO technology ensures that the removal rate of the system is as high as 99.5%, stable output of tertiary water, raw water utilization rate of more than 60%, energy saving and environmental protection; ultra-pure water use cost is extremely low;

7. Cloud service, remotely diagnose the operation of the water machine in advance to ensure the continuous and normal operation of the experiment;

8. The plug-and-play module design does not require professionals to come to the door, and customers can replace it by themselves. Reduce maintenance costs and shorten maintenance waiting time.