According to Qian Bingjiang, Zhang Liying, Wu Yong (Zhejiang Chuanhua Coatings Co., Ltd.) "Development of Effective Anti-fouling Coatings for Coiled Aluminum", the experimental part of the preparation of effective anti-fouling coiled aluminum coatings is as follows.

raw material

Modified polyester resin, amino resin, rutile titanium dioxide, inorganic composite pigment, nano silver ion antibacterial agent, silicone modified polyacrylate, allyl modified silanol catalyst, etc.

formula

Formulations for effective stain-resistant coil aluminum coatings are given in the table.

Table Formulations of effective antifouling coil aluminum coatings

Preparation Process

The effective anti-fouling aluminum coil coating uses a modified polyester resin with a low hydroxyl value and a medium molecular weight as a film-forming substance. In the presence of an acid catalyst, it is cross-linked and cured with a methyl etherified amino resin to form a dense coating film. Its preparation process is as follows: Pre-disperse modified polyester resin, additives, solvents, pigments and other raw materials, then grind them through a sand mill until the fineness is qualified, then add amino resins, catalysts and other additives, after passing the inspection , filter, pack.

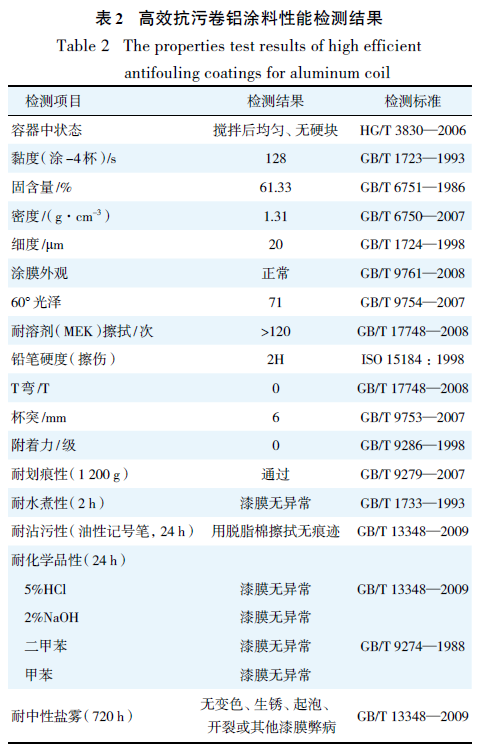

Coating sample preparation and performance testing results

The substrate is pretreated aluminum plate on the production line, with a thickness of 0.40 mm; the coating film is prepared by a stainless steel wire-wound scraping rod scraping method, and the No. 28 wire rod of RDS Company is used to scrape and prepare the test plate, and the dry film thickness is controlled to be 15-20 μm. The curing condition is a laboratory high-temperature oven at 270°C, bake for 30-40 s, and control the maximum substrate temperature (PMT) at 210-224°C.

Performance Test Results of Effective Anti-fouling Aluminum Coatings

The final results show that in the effective anti-fouling aluminum coating, the alkoxymethyl group in the amino resin is the main cross-linking reaction group, which reacts with the hydroxyl group of the modified polyester resin to form a film under acid catalysis, while in On the theme resin, it plays a decisive role in the performance of the entire coating. The catalyst can effectively reduce the baking temperature of the coating, allowing the coating to be quickly solidified at a suitable temperature. The combination of good adhesion can improve the boiling resistance of the coating.

In addition, the addition of special organic silicon additives to funny anti-fouling aluminum coatings can also improve the stain resistance of the product. Tests have shown that when the amount of organic silicon additives is 3%, it will not affect the paint film, and it is durable The staining effect is also satisfactory.

In the selection of pigments, choose inorganic composite pigments with excellent high temperature resistance, light resistance, weather resistance and chemical resistance, which can ensure the consistency of color difference.

Finally, the author mentioned in the conclusion that the research and development of such effective anti-fouling aluminum coil coating products are especially suitable for indoor and outdoor decoration, curtain walls, Ceilings and other places.

For related detailed papers, please refer to "Development of Effective Antifouling Aluminum Coatings for Coatings" published by Qian Bingjiang, Zhang Liying, and Wu Yong on the "Shanghai Coatings" magazine.