The E comprehensive industrial plant is designed according to the standard plant, and its main functions are electroplating production workshop, office, electronic storage, and clean room production workshop. The main design parameters, operation conditions and design experience of the plant before and after the improvement of the pure water design are introduced.

1 Overview

The total construction area of Shenzhen Foxconn E comprehensive industrial plant is about 3.2×104m2, with 4 floors on the ground and a building height of 27.6m. Among them, the first to third floors are the production workshop and office area, and the fourth floor is the chiller equipment room and high-voltage power distribution room. The equipment for production using pure water is mainly concentrated on the first floor of the building.

2 Problem and background description

2.1 Background description

E comprehensive industrial plant has been completed and put into use, but the design of the pure water system was not included in the initial design content. A certain part of the MPE that needs to use pure water for production is the production unit that is finally stationed in the E plant after the internal adjustment of the group. When the unit moved in, there was no room for pure water treatment equipment in the factory except for the production equipment. The pure water indicator reported by the demand unit is: the daily demand is 0.8m3~2.4m3, and the water quality requirement is resistance>10MΩ·m at room temperature). At present, a set of pure water treatment system has been built and put into use in the factory building of F surface treatment plant adjacent to E. The water purification capacity of the system is 50m3/h, and the pure water treatment capacity is 10m3/h. The design processing capacity of the pure water treatment system of F factory is: In addition to ensuring that the needs of each surface treatment production unit in F factory can be met, double the water treatment capacity is reserved for production capacity expansion of the production unit. In order to avoid the impact of peak water consumption and tap water cut-off on production, clean water storage equipment is installed on the third-floor roof of F factory building, with a clean water storage capacity of 100m3, and a pure water storage tank on the first floor with a water storage capacity of 20m3.

2.2 Problem description

In order to solve the problem of using pure water for production in a certain part of plant E, according to the group practice, it is necessary to build a separate pure water treatment system to meet the production needs of this unit.

3 design process

3.1 Main design parameters

The turbidity of the filtered water is less than 1 degree, and the residual chlorine is Between 6.5~7.5;

System water production: filtered water 10m3/h, pure water 5m3/h, actual daily water consumption 2.4m3.

3.2 Water source selection

The water source is municipal tap water, and the group's reservoir is used as the raw water storage tank.

3.3 System design

The water system design (see Figure 1) is a constant flow system, and the pipeline adopts a single- pipe sequence. The water volume is adjusted manually through the regulating valve on the pipeline. The RO pure water storage tank is installed on the four-story roof and doubles as an expansion tank.

3.4 Automatic control design of pure water system

Both fine sand filter and activated carbon filter are controlled by PLC (ProgrammableLogicController) to realize automatic operation and backwashing.

However, through the design of the above pure water system, it can be found that a newly built pure water system has the following defects:

①The project cost is high; ②The construction is difficult; ③The construction period is long; ④The equipment occupies a large area; ⑤The operating cost is high; ⑥The maintenance of the equipment is troublesome; The cost performance of the investment is low. Especially for point ④ above, since the newly-built system requires a building area of at least 90m2, and there is no room for equipment in the building, so the newly-built system needs to be adjusted greatly, which is not suitable for actual needs.

4 Improve ideas and goals

4.1 Ideas for improvement

In view of the above problems and combined with the design and planning scheme, it is found that the large investment in equipment caused by the complexity of the system process is the ultimate cause of the above defects.

So how to simplify the system process to reduce equipment investment is the root of solving the problem.

According to the process principle of pure water treatment, it is found that the quality of water source is the direct cause that restricts the complexity of the system process and the investment in equipment. Therefore, improving the system requires improving the water source.

In order to ensure the technical rationality of the system, the plan to improve the water source is carried out on the basis of the original planning and design of the technological process. The key point is to simplify the water treatment process on the premise of using the pure water of the F factory building directly as the water source. achieve the goal of effective improvement. In the process of modifying the plan, it is found that the use of the pure water system of plant F still needs to demonstrate whether the following points are true:

①F厂房内所有表面处理生产设备与某部生产设备同时使用纯水的情况是否可避免。因F厂房内表面处理单位的产能提升,原先预留的一倍的纯水处理能力已经所剩无几,偶尔会出现高峰用水缺水的现象。②F厂房的纯水各项技朮指标是否完全满足塑模加工一部线割机的水质要求。表面处理与精密模块加工所用纯水的指标要求略有差异。③从F厂房的纯水管路末端接引至E厂房后,出水压力是否可满足生产设备很不利环路的水头要求。E厂房纯水使用区域与F厂房纯水处理设备间存在100m左右的距离﹐F厂房的纯水处理管路末端管径DN32mm﹐纯水泵的流量为10m3/h,扬程25m。

4.2计算与讨论结论

1)E厂房内某部使用纯水可进行间歇式取水﹐

并可通过人为调整方式避免与F厂房内表面处理各单位同时使用纯水﹐该部门使用纯水的周期较为固定﹔约为每三天换水补水一次,每次换水补水的使用时间约为3h。其用水特点规律易于掌控﹐可解决高峰用水同时使用的问题。

2)将某部的使用纯水的技朮要求参数与F厂房

内表面处理生产设备所用纯水的技朮指标﹑系统设计数据及测试仪表的数据进行对比后得知,F厂房已建的纯水系统将同等水源的原水处理后所得到的纯水各项技朮参数均符合某部生产设备的技朮要求。

3)通过水力计算,采用DN32mm管路作为E厂房

引自F房纯水系统的纯水干管,在很不利末端采用DN15mm作为末端支管,可满足很不利环路的水压要求。

4.3改善目标

在充分满足使用单位需求的前提下实现以下目标﹕

①资源优化配置﹔②设备合理;③降低工程造价;④缩短施工周期;⑤降低工程难度;⑥减少设备占用面积;⑦减少设备运行保养费用;⑧实现“零”故障﹐“零”保养。

5改善方案实施

考虑集团内各个单位发展迅速,产能扩充能力较快较强的现实,因此设计两套方案进行逐步实施。5.1方案1

The pure water is directly connected to the main water distribution point of the E factory building from the F factory building through the pipeline, and then connected to the various water equipment points of a certain department through the PVC water supply pipe from the general water distribution point. And set up the water pipe reserved interface on the pipeline at the position of the main water distribution point for the implementation of plan 2.

If the production in F factory building and E factory building expands rapidly, and there are frequent peaks and simultaneous water consumption, plan 2 will be implemented.

5.2 Scheme 2

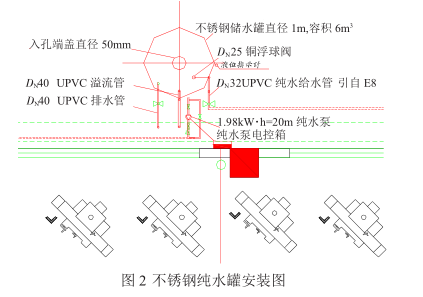

A pure water pump is added at the beginning of the pure water pipeline leading from the F workshop to the E workshop to increase the water supply pressure in the pipeline to achieve the purpose of hydraulic transportation. At the same time, a stainless steel pure Water Tank with a volume of 6m3 is installed at the end of the pipeline to store pure water and reduce interference between units. The pure water to each machine is transported to each water point by mechanical transportation through another pure water pump as a power source (see Figure 2).

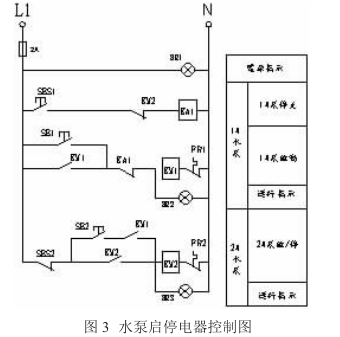

①Electrical control for starting and stopping between the two water pumps at the front and rear ends (see Figure 3)

②In order to realize automatic control, it is necessary to add sensors and test instruments to the water supply pipeline and machinery equipment .

6 Situation after improvement

Through actual operation, plan 1 is adopted, that is, without using a pure water pump, the pure water is directly connected from the F plant to a certain part of the E plant through the pipeline to meet its pure water use requirements.

Through the improvement of the system design, the actual is only 3,800 yuan. If calculated according to the calculation of a new pure water system, the investment of 158,600 yuan is needed, that is, the initial investment of the equipment can be reduced at one time through the improvement of the design plan. 154,800 yuan.

Here, only the cost saved by the initial investment of the equipment is calculated, and the labor management cost, maintenance cost, power loss, etc. that will be formed after the new pure water equipment is put into use have not been calculated.

7 Epilogue

The method of engineering investment economy is to improve or improve the system design itself. After fully be carried out to achieve the purpose of reducing initial investment and optimizing resource allocation.