The fineness of paint is to measure the size and uniformity of dispersion of particles such as pigments and extender pigments in the paint, and the unit is expressed in microns (μm). Both the back paint and the top coat of the roll material have high requirements on the fineness, which is generally controlled at 15-25 μm, while the fineness of the primer can be coarser, generally controlled at 20-40 μm. Generally speaking, the fineness is small, which can make the coating smooth and uniform, beautify the appearance and decorative performance, and have good mechanical properties.

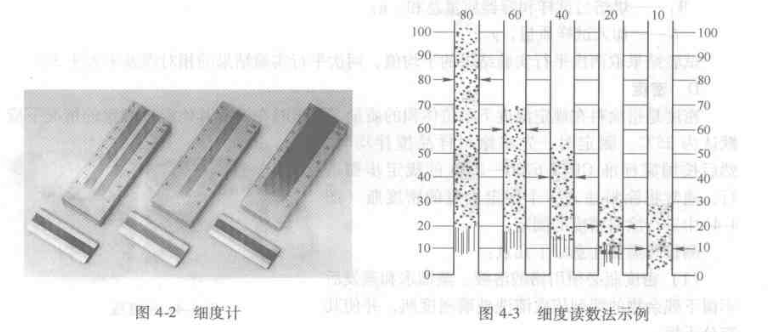

The measurement of fineness mainly adopts a scraper Fineness Meter with a range of 50 μm (as shown in Figure 4-2), and the inspection method and standard equivalent adopt the national standard GB 1724-89 (79) coating fineness measurement method. The scraper fineness gauge is constructed as a polished flat plate made of tool alloy steel. There is a groove on the board, and there are scale marks on the edge of the groove, which are divided into several specifications such as 0~50μm, 0~100μm, and 0~150μm. Comes with a spatula. Both edges are ground.

The following points should be paid attention to when measuring:

(1) Choose Fineness Meters with different measuring ranges according to different coating types, and choose a Fineness Meter with a large range for rough measurement.

(2) Drop about 1~2g of paint sample on the top of the side plate, not too much or too little.

(3) Hold the scraper with both hands so that the scraper is in vertical contact with the surface of the polished plate, and pull it from the deep part of the groove to the submerged part at a suitable speed (generally takes 3s), so that the sample fills the groove and leaves no trace on the plate. More than expected.

(4) Read quickly in the sun (should not exceed 5s), so that the line of sight and the surface of the groove form an angle of 15°~30°, and read at the place where more than three particles are evenly exposed. The reading method is shown in the figure below ( 4-3)